Printing equipment and MES docking method and device based on industrial internet

A technology for industrial Internet and printing equipment, applied in the field of interfacing between printing equipment and MES system based on industrial Internet, it can solve the problems of data connection restoration, low stability of printing process, insufficient security warning, etc., so as to accurately locate the fault location and reduce the fault. Scope of investigation, effect of improving stability and adaptability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

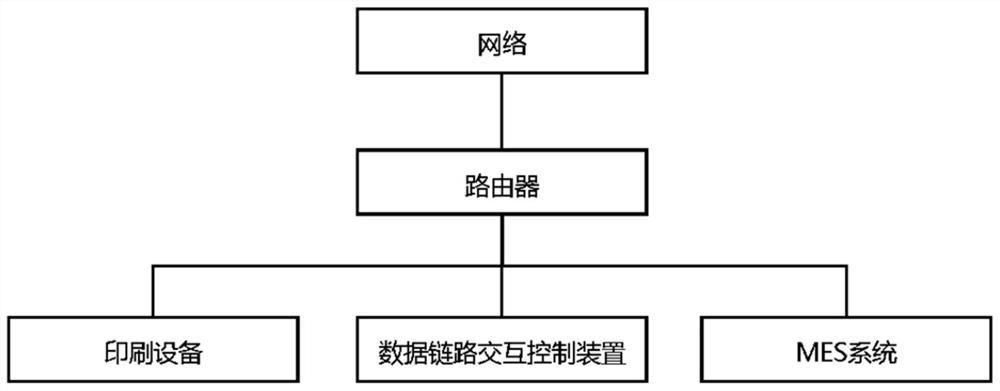

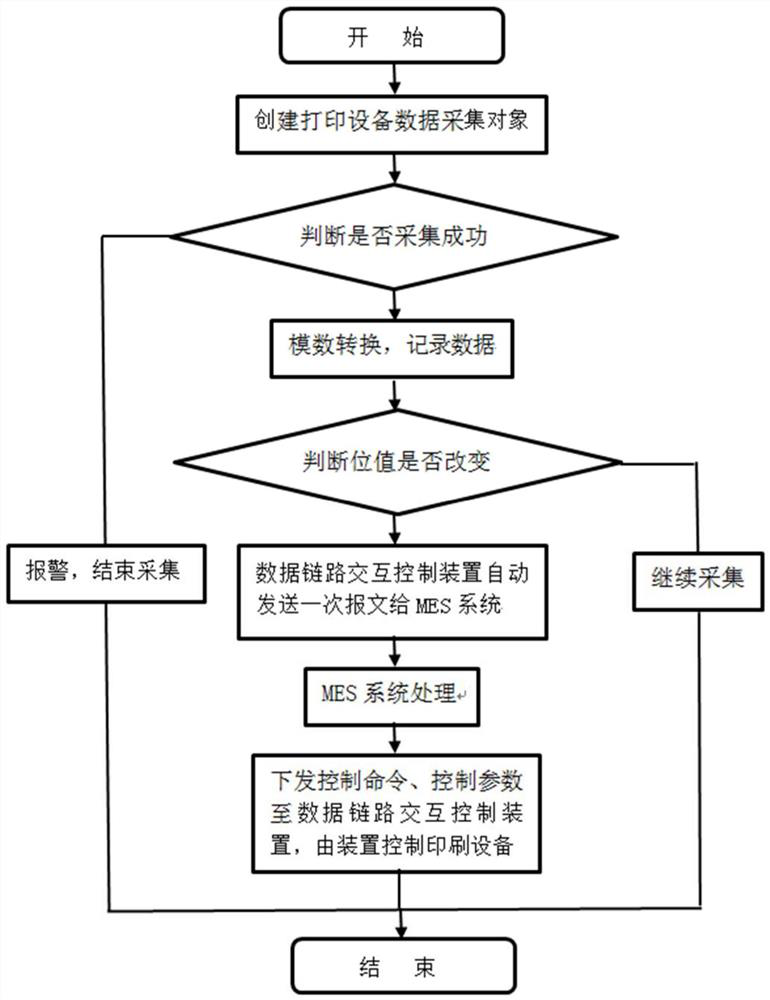

[0030] Such as figure 2 As shown in the figure, a method for connecting printing equipment and MES system based on the industrial Internet, builds the middle platform of the equipment through the data link interactive control device, and the data link interactive control device is respectively connected with the printing equipment and the MES system for data docking and equipment management. It includes that the MES system sends control commands and control parameters to the data link interactive control device, and then controls the printing equipment, and at the same time obtains the status information, alarm information and parameter data information of the printing equipment from the data link interactive control device, and then uploads them to the MES system, equipment management includes printing work order management, equipment abnormal alarm and record, preventive maintenance reminder and record, remote maintenance.

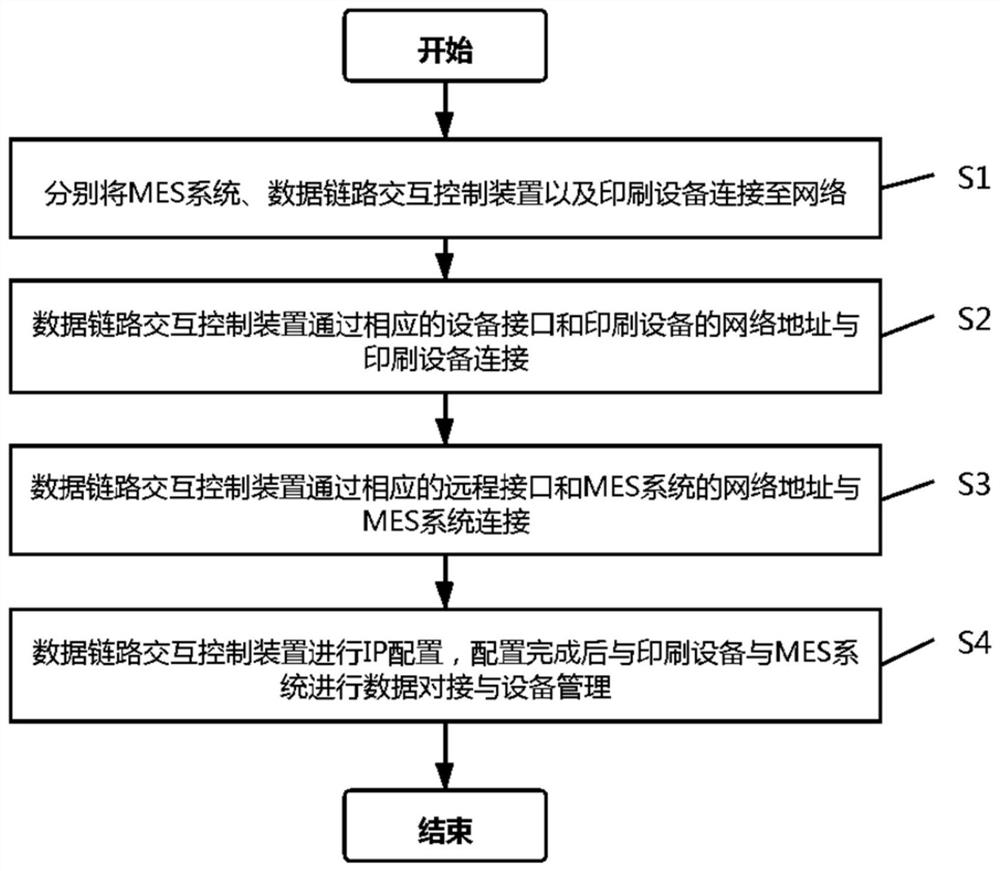

[0031] Such as figure 1 As shown, the data link ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com