Transformer insulator cleaning robot

A technology for cleaning robots and transformers, which is applied in the direction of manipulators, chemical instruments and methods, cleaning methods and appliances, etc., which can solve the problems of manual cleaning in power outages, low efficiency, and large safety hazards, and achieve flexible and reliable costs, ensure safety, and structural design reasonable effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0016] In order to make the object, technical solution and advantages of the present invention clearer, the present invention will be further described in detail below in combination with specific examples and with reference to the accompanying drawings.

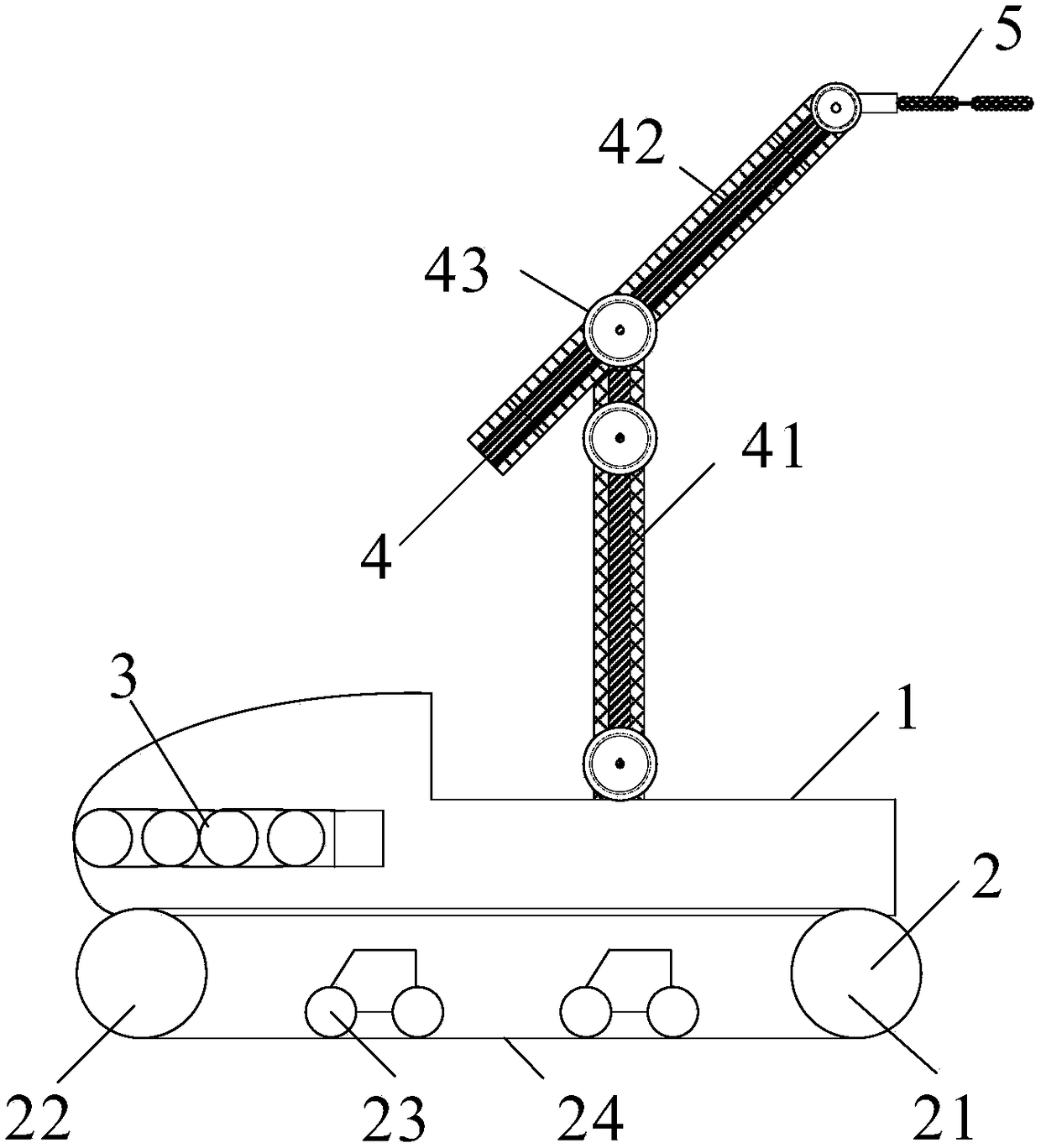

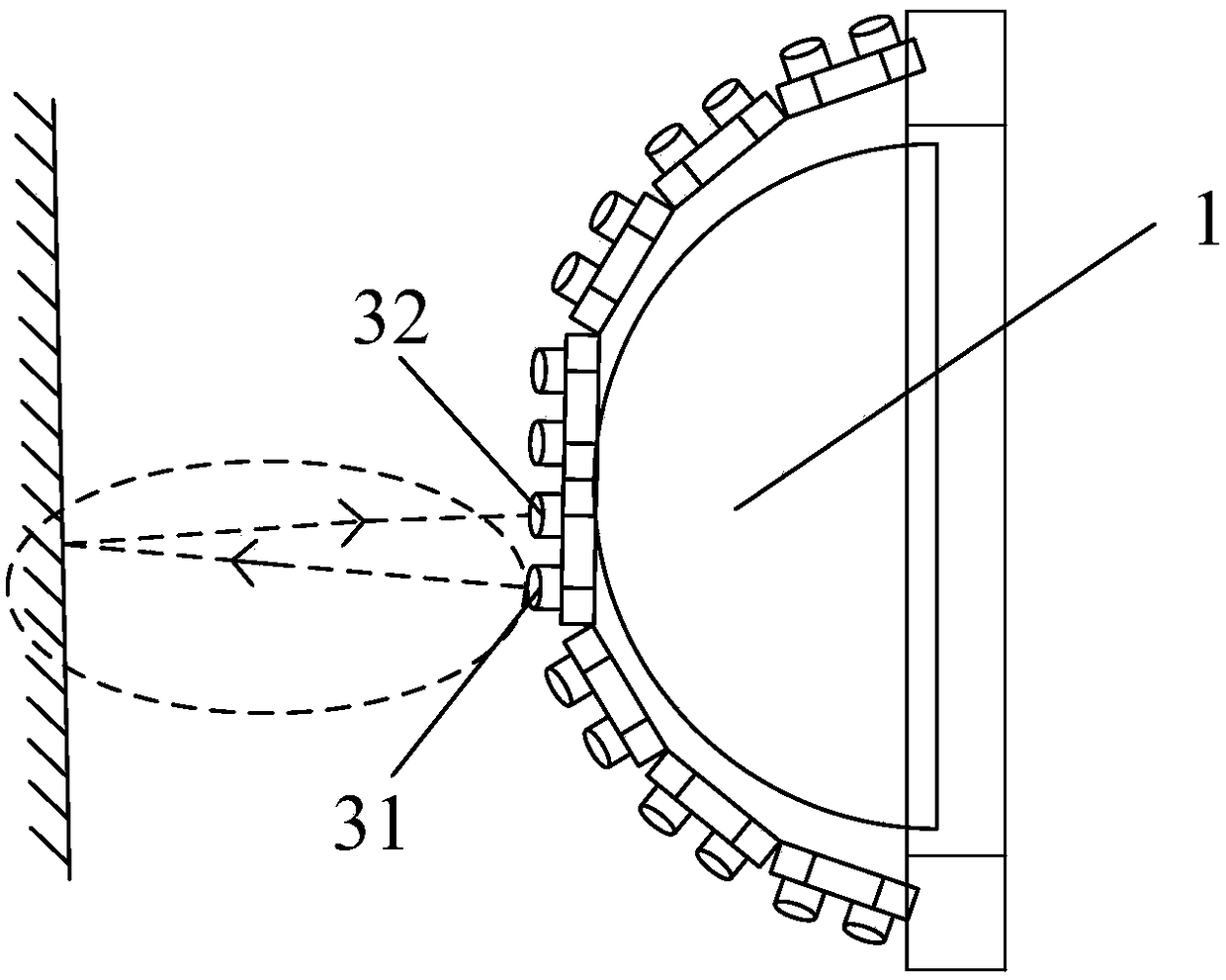

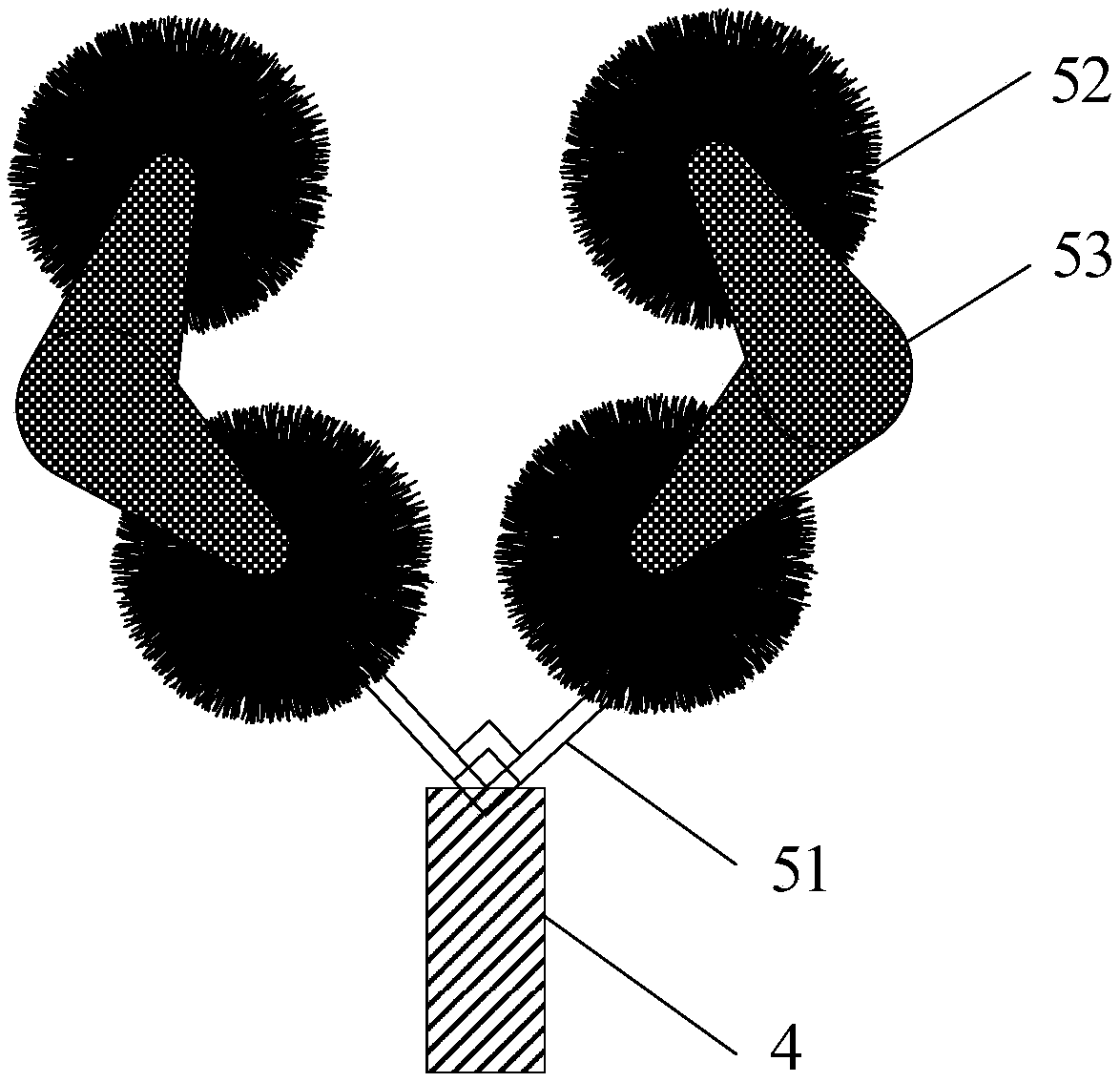

[0017] see figure 1 , a transformer porcelain vase cleaning robot, comprising a mobile robot main body 1, a traveling mechanism 2, an ultrasonic ranging mechanism 3, an adjusting mechanism 4, a cleaning mechanism 5 and a control circuit.

[0018] The control circuit is arranged in the main body 1 of the mobile robot, and its function is to realize the control of the robot. The control circuit is mainly composed of a main controller, a walking drive circuit, a walking motor, a vertical telescopic drive circuit, a vertical telescopic motor, a horizontal telescopic drive circuit, a horizontal telescopic motor, an angle adjustment drive circuit, an angle adjustment motor, a rotation drive circuit and a rotation motor. An output...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com