Calculating method for compensation quantities of hull segments

A calculation method and compensation amount technology, which is applied in the calculation field of hull section compensation amount, can solve the problems of prolonging the manufacturing cycle, waste of hull accuracy, and large trimming amount, etc., and achieve the effect of improving manufacturing accuracy and saving required materials

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0022] The specific embodiments of the present invention will be described in further detail below in conjunction with the drawings and embodiments. The following examples are used to illustrate the present invention, but not to limit the scope of the present invention.

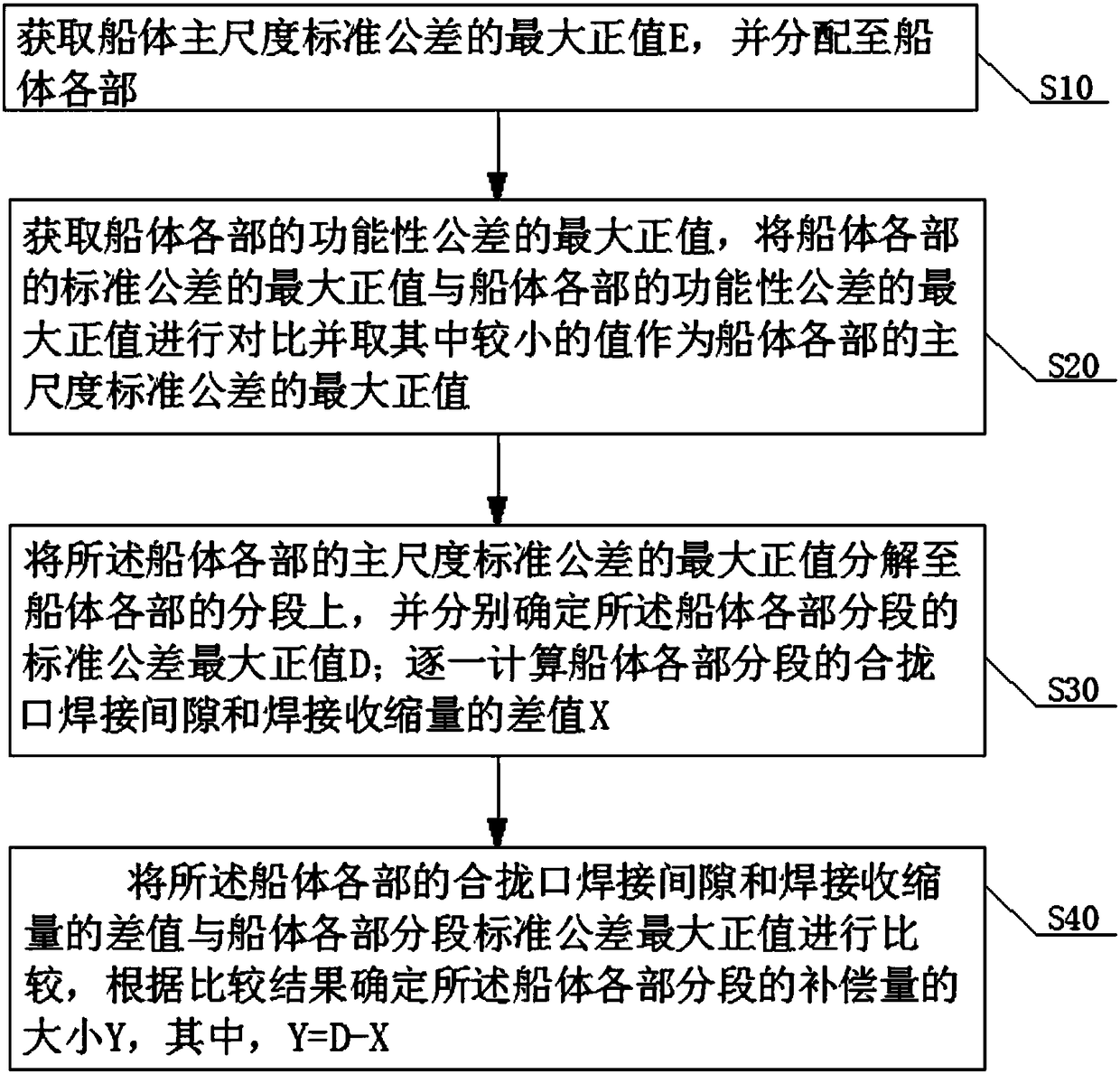

[0023] Such as figure 1 Shown is a flow chart of a method for calculating the amount of compensation for hull segments provided by the present invention, which includes the following steps:

[0024] S10. Obtain the maximum positive value E of the standard tolerance of the main hull dimension, and distribute it to each part of the hull to obtain the maximum positive value E1,..., EN of the standard tolerance of each part of the hull, where E=E1+……+EN, N ≥2;

[0025] Specifically, the maximum positive value E of the standard tolerance of the main hull dimension in the present invention is obtained by consulting the manual, where the maximum positive value E of the standard tolerance of the main hull dimension is ass...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com