Integrated tying and packing machine and packing and tying method for packing bags

A packaging bag and all-in-one machine technology, applied in packaging, bundling materials, transportation and packaging, etc., can solve the problems of relying on operators, affecting the quality of packaging, and difficult to stack neatly, so as to avoid uneven stacking, ensure scalability, The effect of complete separation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

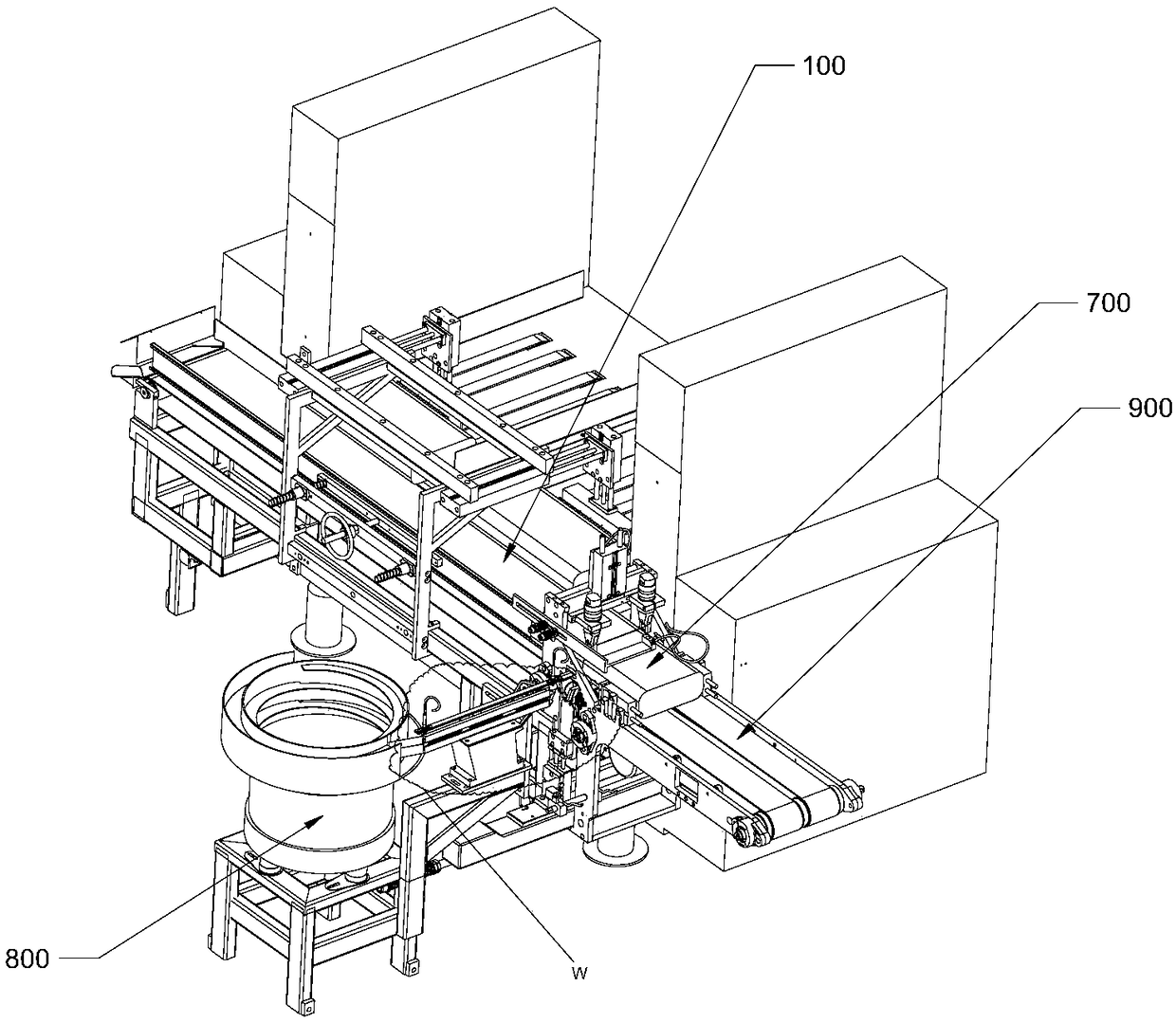

[0065] One aspect of the present invention provides a packaging bag binding and packing integrated machine, which includes a packaging bag binding machine, a packaging bag conveying device 100 and a packaging bag packing machine arranged in sequence in sequence.

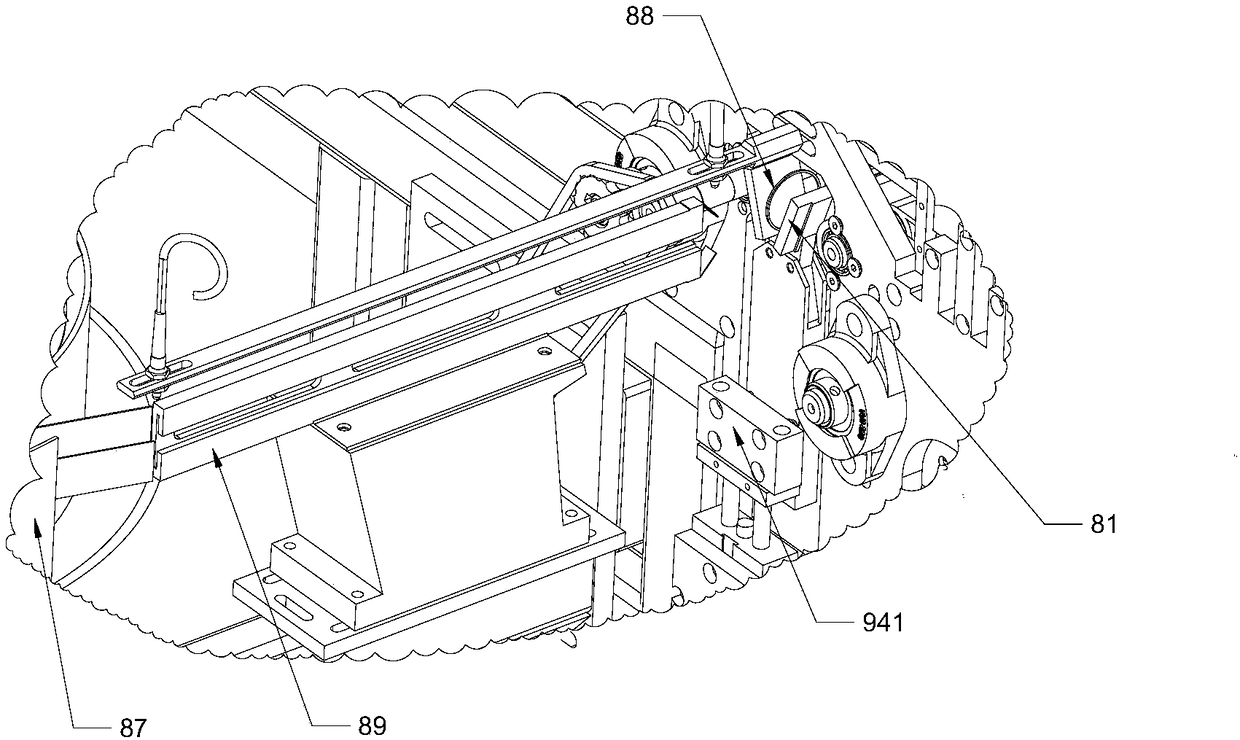

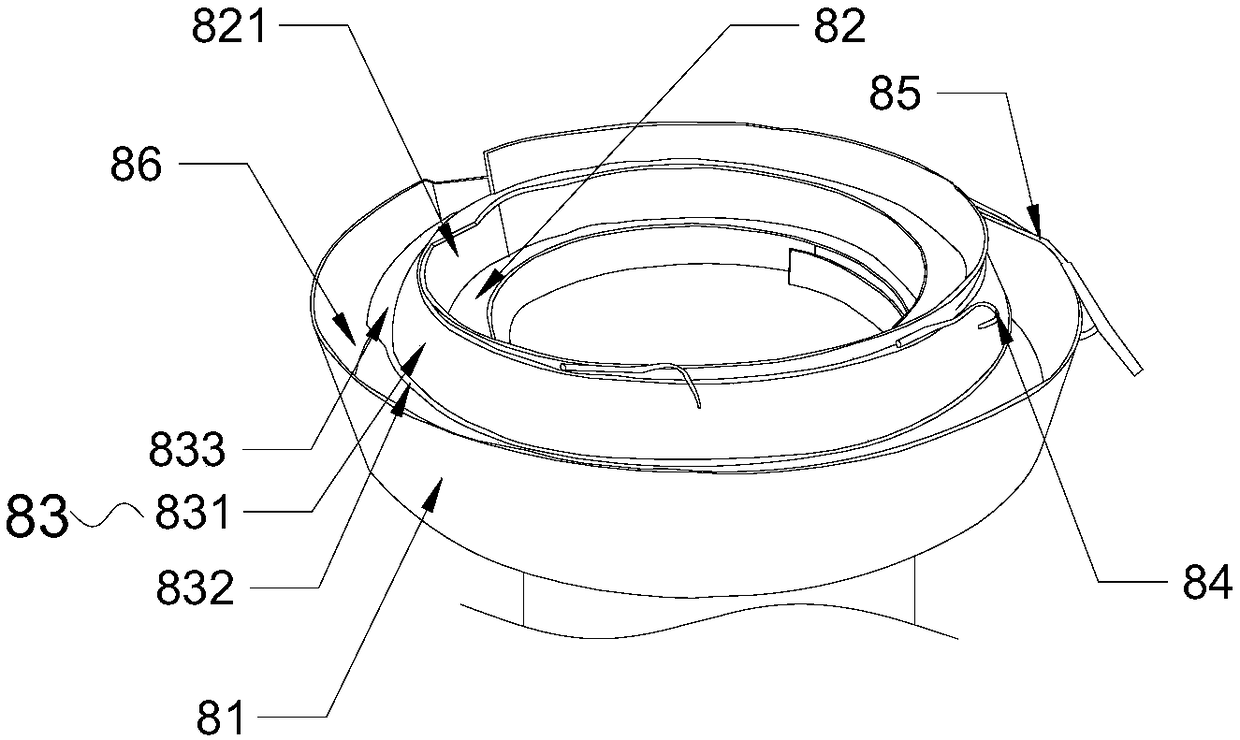

[0066] The above-mentioned packaging bag binding machine includes a rubber band screening device, a rubber band stretching device and a packaging bag conveying device, and the rubber band screening device includes a vibrating plate, see Figure 1-Figure 8 , the vibrating plate includes a hopper 81 and a feeding track 82, the outer edge of the feeding track 82 is fixed on the inner wall of the hopper 81, the feeding track 82 spirals up, the vibrating plate works, the rubber band at the bottom of the hopper 81 spirals up through the feeding track 82, and the feeding The upper end of the track 82 is provided with a feed port 821, and the rubber band is delivered to the outside of the feed track 82 through the feed port 8...

Embodiment 2

[0113] The push plate telescopic device 300 includes at least two push blocks 301 arranged in the same plane, between any two adjacent push blocks 301 in the horizontal direction, and between any two adjacent push blocks 301 in the vertical direction. Through the sliding connection of the guide posts, at least one compression spring 302 is installed between any two adjacent push blocks 301 in the horizontal direction and between any two adjacent push blocks 301 in the vertical direction; this embodiment also includes There are at least two braces 402 with adjustable spacing, and the inner surfaces of the braces 402 are adapted to the shape of the push block 301 located on the edge.

[0114] Through the push plate telescoping device 300, self-adaptive adjustment can be realized in the plane where the push block 301 is located and in the direction (front and back direction) perpendicular to the push block 301, thereby ensuring surface contact between the push block 301 and the wo...

Embodiment 3

[0124] The present invention also includes the blanking door and the opening and closing mechanism of the blanking door, the control end of the opening and closing mechanism of the blanking door is connected with the signal of the controller, and the blanking door can be opened and closed on the blanking bin through the opening and closing mechanism of the blanking door On the opening of the upper end of 200, the opening and closing mechanism of the blanking door is connected with the controller signal. Specifically, the blanking door is a pair of flashing plates 201 arranged horizontally, and the two flashing plates 201 respectively reciprocate along the front and rear directions under the action of two cylinders 202 . A blanking door is set, and when the packaging bag conveying device 100 delivers the packaging bag 700 to the opening above the blanking bin 200, the blanking door is opened, and when the packaging bag conveying device 100 has finished conveying the packaging ba...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com