Transport mechanical arm with firm clamping function

A kind of handling machinery and firm technology, applied in the field of handling mechanical arms, can solve the problems of inability to realize mechanical self-locking and easy loosening of clamping parts, achieve good clamping and fixing effect, and realize the effect of mechanical self-locking

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

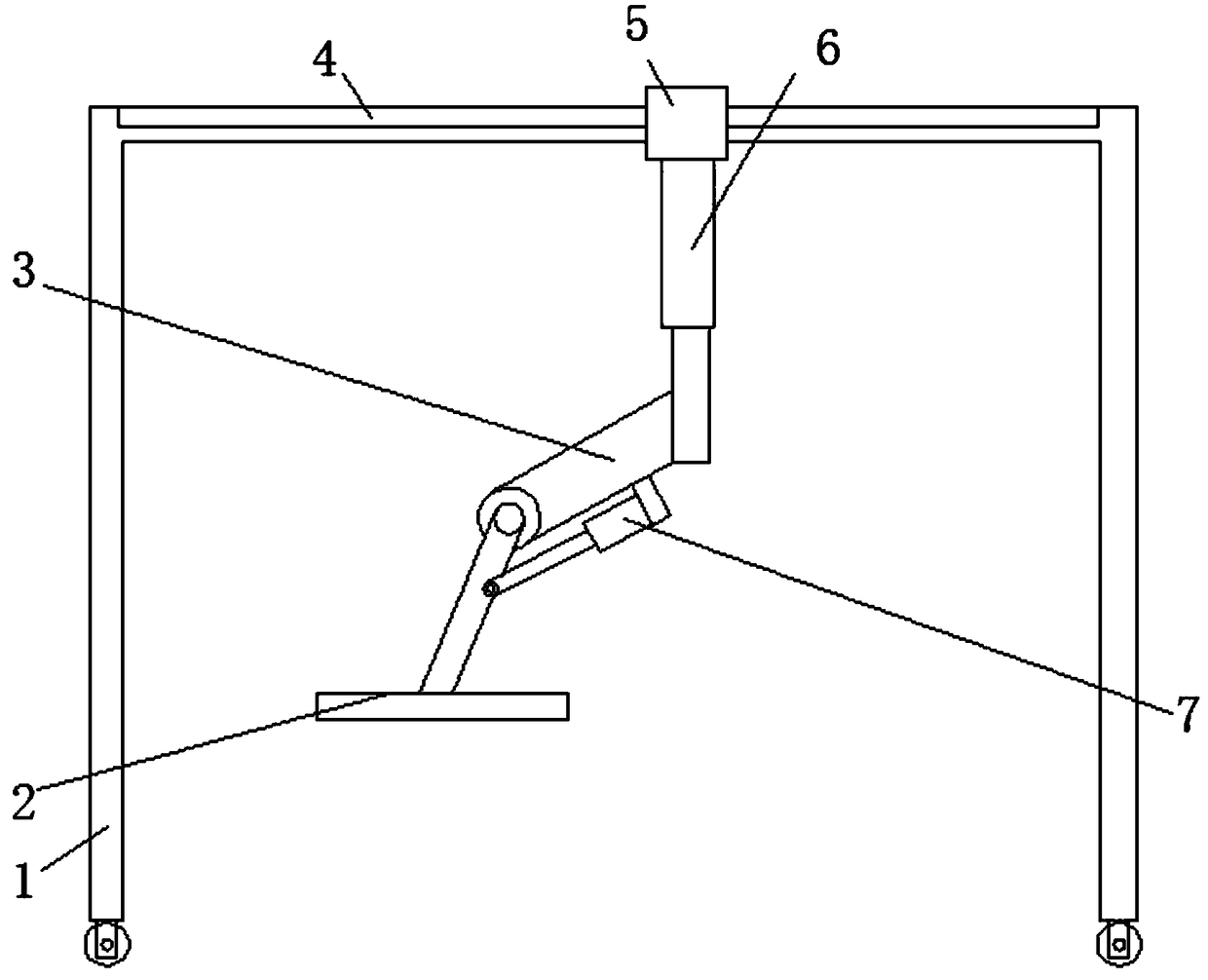

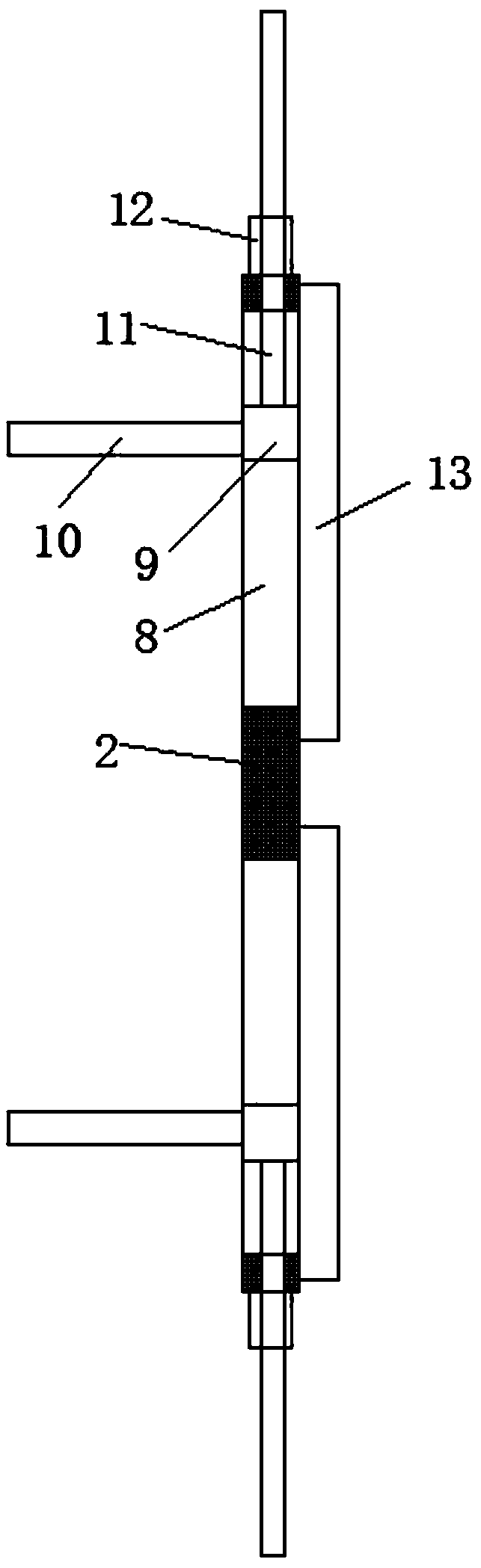

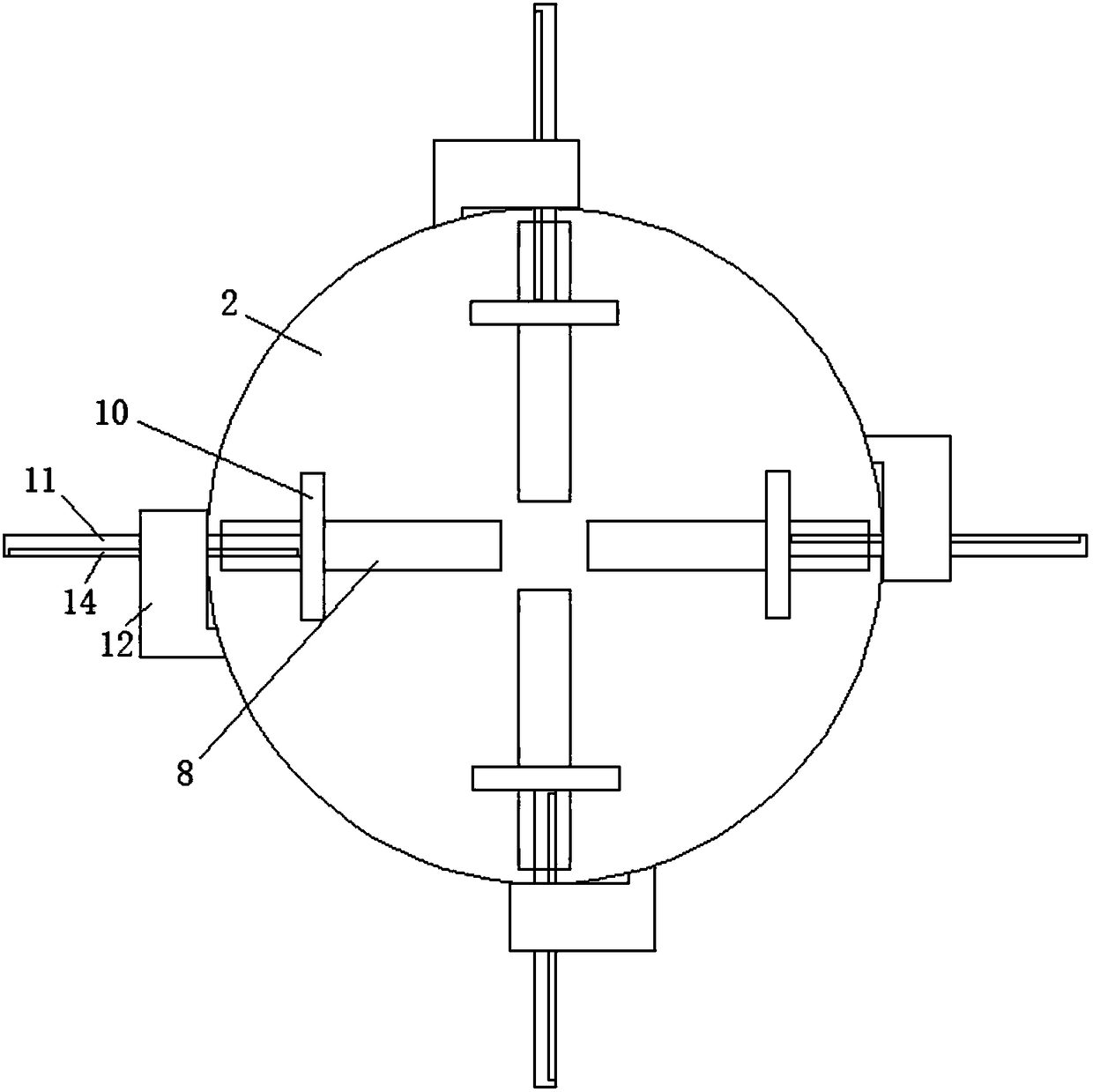

[0022] Embodiment: When in use, the device is moved to the vicinity of the workpiece to be transported through the universal wheels, the first rodless cylinder 4 drives the movable frame 5 to move on the fixed frame 1, and the telescopic column 6 drives the first connecting rod 3 to move up and down , the single-head cylinder 7 drives the second connecting rod to rotate on the first connecting rod 3 to adjust the angle, the mounting plate 2 moves to clamp the object, and the electromagnets 17 in the four fixed shells 12 are energized, and the electromagnets 17 and the magnet block 18 are adsorbed to each other, driving the movable block 15 to move, the teeth on the movable block 15 are not meshed with the rack 14, and the spring 16 is compressed at the same time, and the four second rodless cylinders 13 act to drive the slider 9 to slide in the through hole 8 , drive the positioning rod 11 to move in the fixed shell 12, and drive the clamping plate 10 to clamp the workpiece. N...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com