Brick space expanding and separating device for machine-made baking-free brick discharging machine

A technology of non-burning bricks and expanders, which is applied in the direction of manufacturing tools, ceramic molding machines, auxiliary molding equipment, etc., can solve the problems of small gaps between bricks, low efficiency, laborious and other problems, and achieve high work efficiency, The effect of reliable operation and simple structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

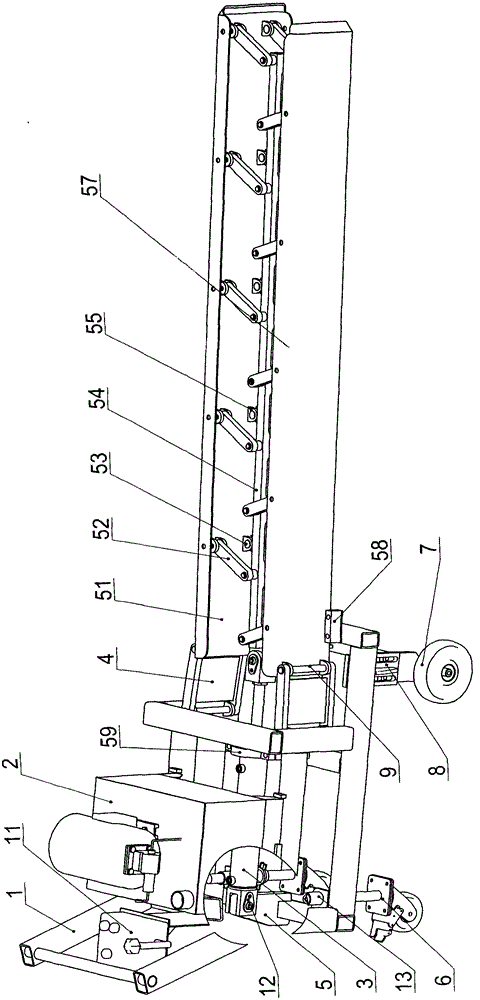

[0009] like figure 1 As shown, a mechanism of unburned bricks out of the machine brick distance expander, including a base frame 1 and a handle connected to the rear end of the base frame, consists of a C-shaped groove plate, a push rod, a hinge plate, a pin shaft and a connecting rod The expansion device constituted, as well as the hinge assembly, hydraulic cylinder, hydraulic pump station, control box and road wheels.

[0010] The C-shaped groove plates in the above-mentioned expansion device 5 are left and right C-shaped groove plates 51, 57 with opposite notches. Two rows of hinge plates 55, between the hinge plates of the upper and lower rows and the upper and lower side plates at the opening end of the notch of the C-shaped groove plate, are respectively connected with one end of the connecting rod 52 through the pin shaft 53, and the other ends of the connecting rod pass through respectively. The pin shaft is connected to the upper and lower end faces of the push rod 5...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com