Construction method of overhead fast longitudinal moving auxiliary beam

A construction method and technology of convenient beams, which are applied in the direction of laying tracks, roads, and the bottom layer of roads, etc., can solve problems such as large line stability and operation safety, heavy maintenance workload, and large safety hazards, and achieve a smooth and smooth beam moving process , shorten the construction period, ensure stability and driving safety

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

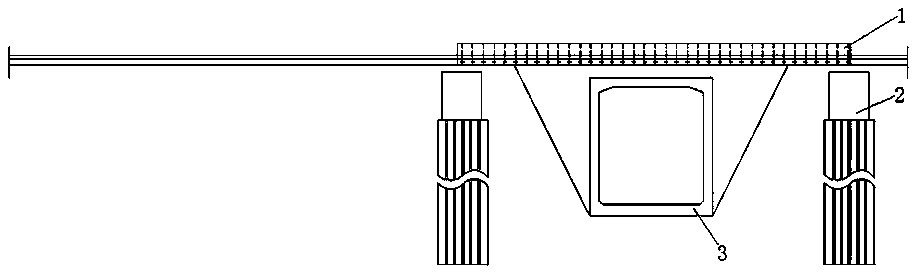

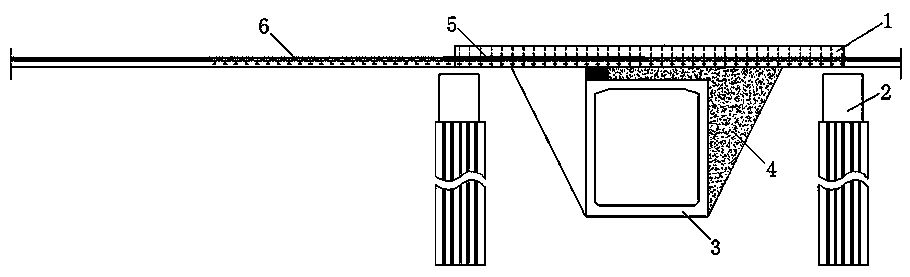

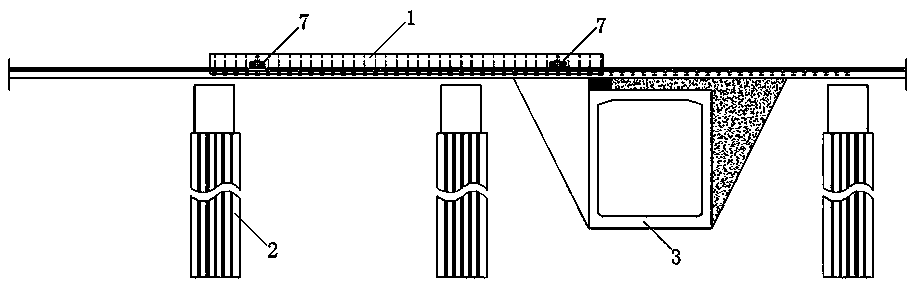

[0020] Embodiment: In this embodiment, the construction method of the suspended quick-moving convenience beam is used in the continuous jacking construction of the porous box culvert passing through the overpass. This construction is used to jack up and pass several independent box culverts one by one Existing railway. like Figure 1-6 As shown in the construction steps diagram, the continuous jacking construction can include the first box culvert 3, the second box culvert 8 and the third box culvert 10, and the three box culverts are respectively jacked one by one and pass through the existing railway above them to form The overpass can realize the mutual non-interference and high-speed passage of urban traffic and railway transportation.

[0021] This embodiment is specifically described in conjunction with the continuous jacking construction steps of the porous box culvert passing through the overpass, as follows:

[0022] 1) if figure 1 As shown, the foundation reinforc...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com