Construction method for dismantling wide continuous beam over railway business line

A construction method and cross-railway technology, applied in bridges, bridge maintenance, bridge reinforcement and other directions, can solve the problems of high impact on railway traffic safety, many cross-railway points, and complex construction process, so as to reduce traffic risks and reduce construction costs. , the effect of simple construction process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0033] The present invention will be further described below in conjunction with accompanying drawing by non-limiting embodiment:

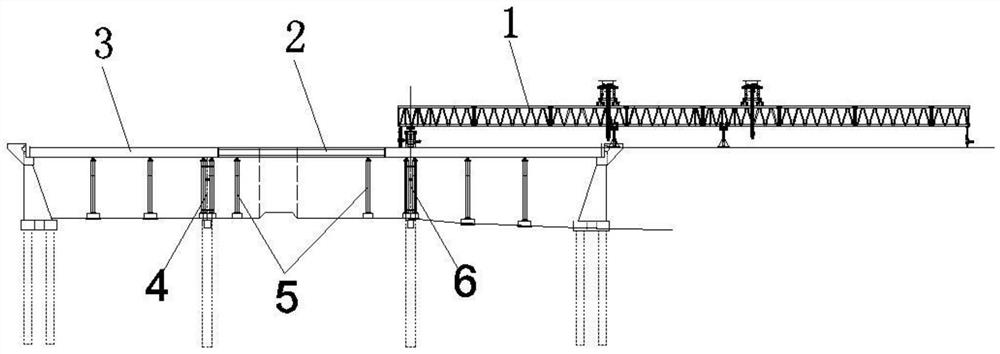

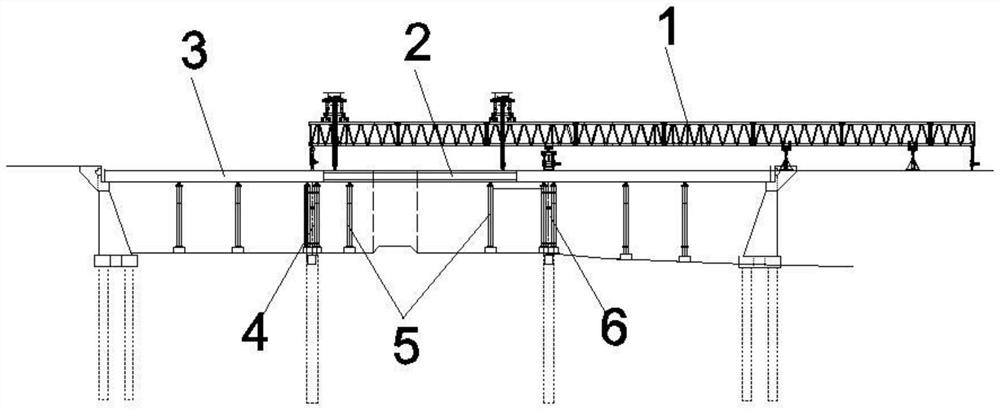

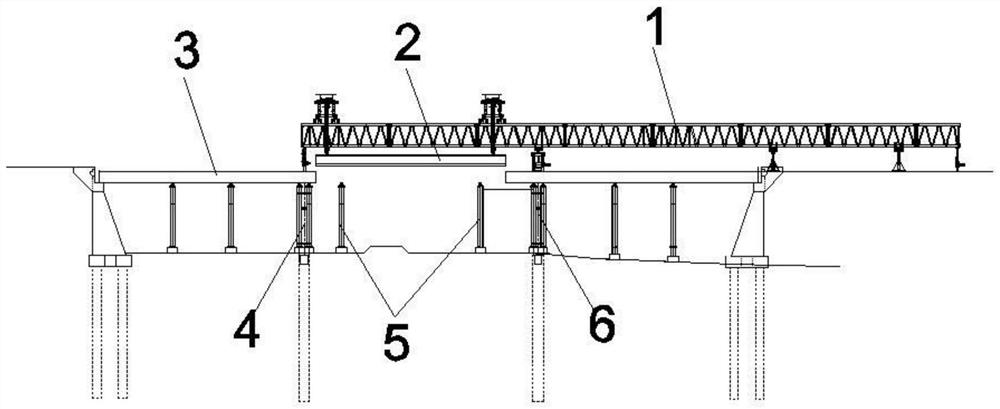

[0034] As shown in the accompanying drawing, a construction method for dismantling the wide continuous beams on the business line of the railway, which uses a bridge erecting machine to carry out integral hoisting and dismantling of the beam body across the railway section. The bridge erecting machine is an existing highway bridge erecting machine. It is prior art. The construction process is as follows: bridge erecting machine fulcrum setting → removal of the bridge deck system (near the business line) → removal of the anti-collision wall and flange plate (in the blockade point) → assembly of the bridge erecting machine, through holes → horizontal cutting of the beam body (near the business line) )→Beam binding and hoisting (within the blockade point)→Bridge erecting machine withdrawal hole (within the blockade point)→Elimination of side span bea...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com