Method for sorting white light LED

A technology of LED chips and white light, applied in the field of LED lighting, can solve the problems of inconsistency in positions, inconsistencies in lenses, and inconsistency in light color space, etc., and achieve the effect of fewer sub-blocks, improved competitiveness, and slight color difference

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

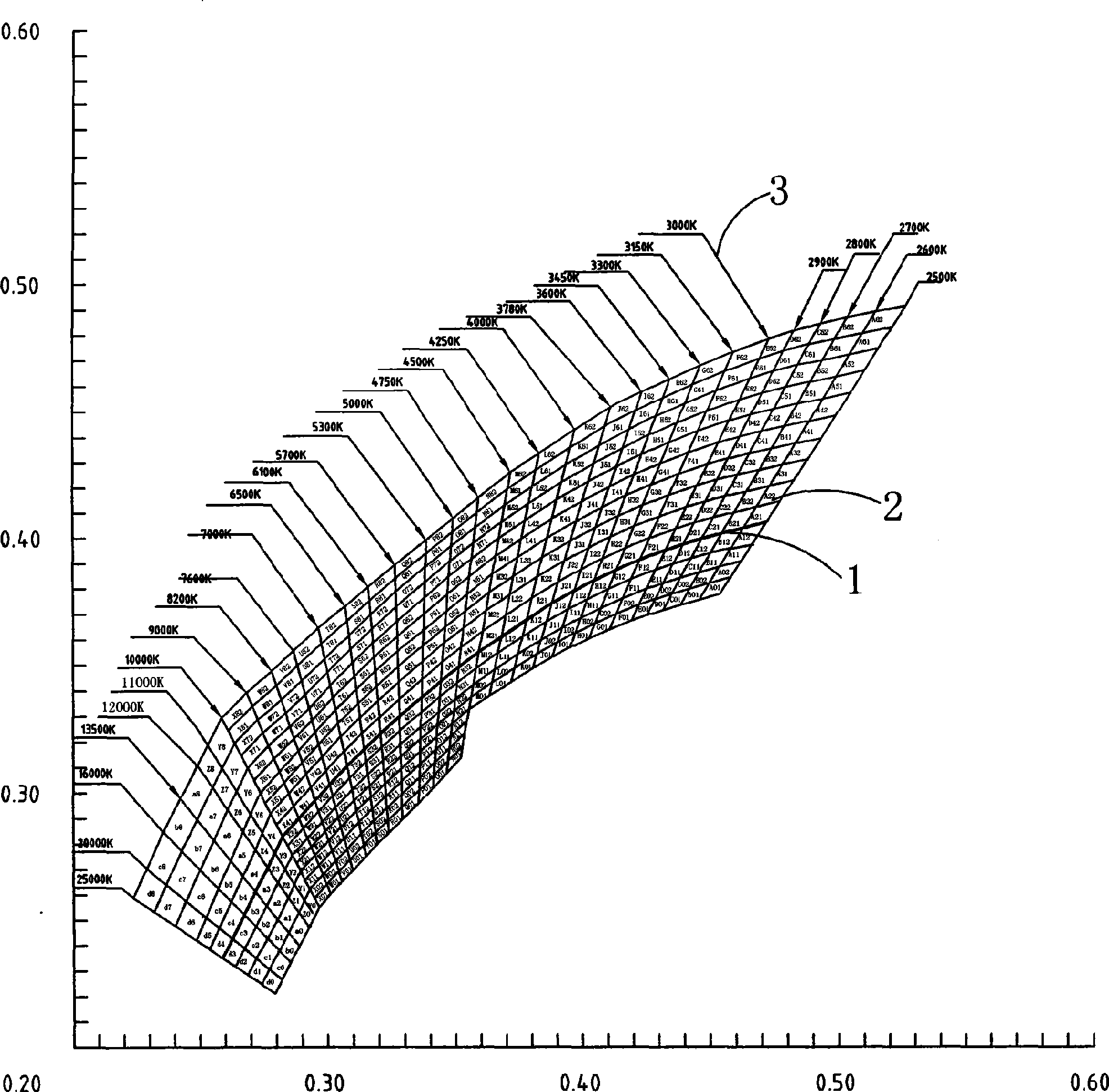

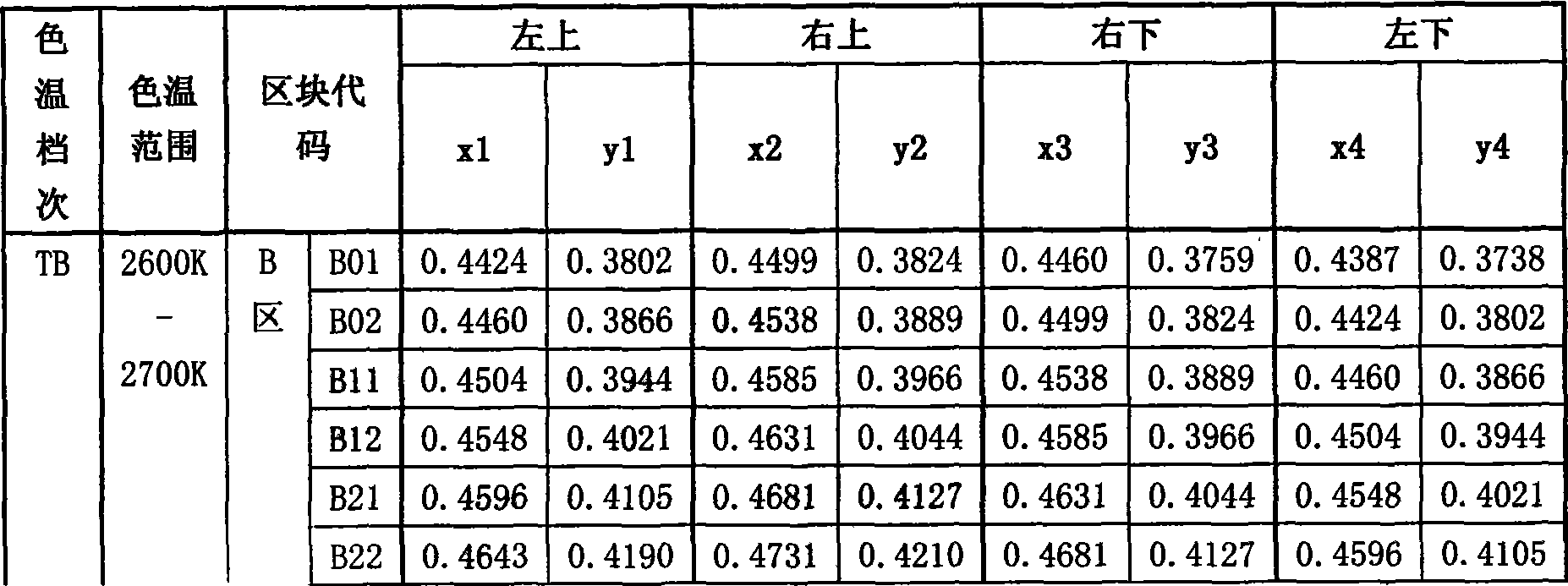

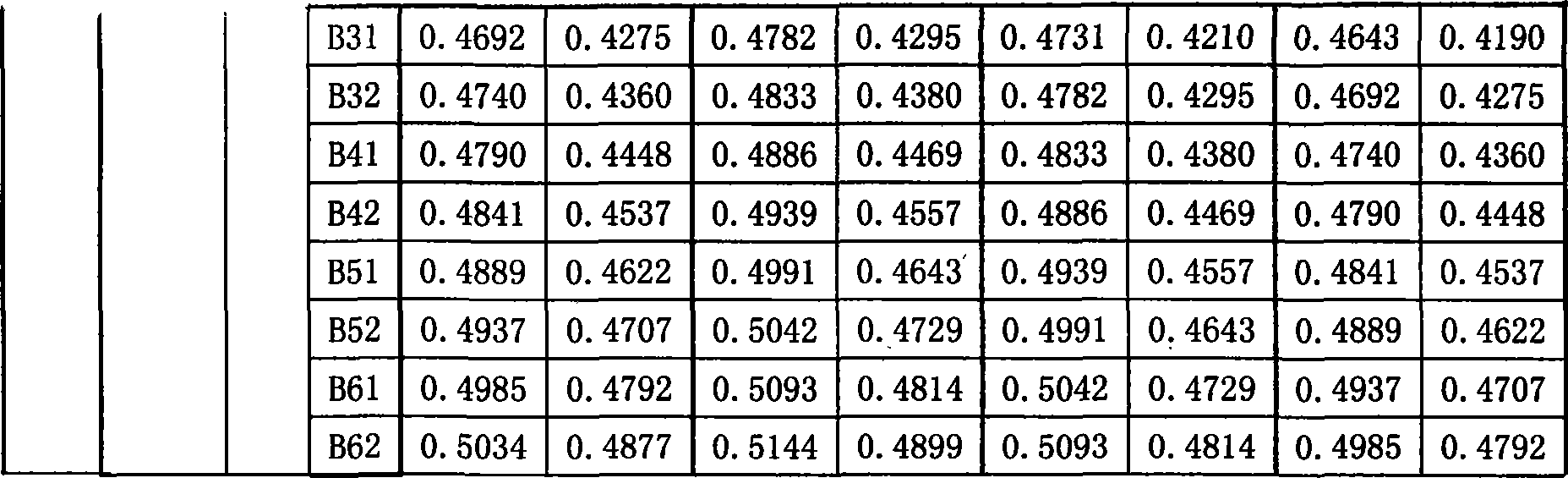

[0041] Such as figure 1 As shown, when sorting LED white light, the input voltage difference on the spectrometer is 0.10v, the brightness multiplier value is 1.19, the color difference value between the two points with the smallest color difference on the two curves is 0.0025uv, and the color temperature range is 2600K~2700K , make spectroscopic B block (such as figure 1 shown) and the coordinate table TB corresponding to the block:

[0042]

[0043]

[0044] Find the coordinate values corresponding to the four vertices of all blocks within the range of block B, input them into the automatic spectrometer, the automatic spectrometer will measure and sort the LEDs, and assign the LEDs to different types, all white LEDs in block B will be sorted out.

Embodiment 2

[0046] Such as figure 1 As shown, when sorting LED white light, the input voltage difference on the spectrometer is 0.20v, the brightness multiplier value is 1.20, the color difference value between the two points with the smallest color difference on the two curves is 0.0035uv, and the color temperature range is 6500K~7000K , make a spectroscopic T block (such as figure 1 shown) and the corresponding coordinate table TT of the block:

[0047]

[0048]

[0049] Find the coordinates corresponding to the four vertices of all blocks within the T block, input them into the automatic spectrometer, the automatic spectrometer will measure and sort the LEDs, and assign the LEDs to different types, all the white LEDs in the T block will be sorted out.

Embodiment 3

[0051] Such as figure 1As shown, when sorting LED white light, the input voltage difference on the spectrometer is 0.30v, the brightness multiplier value is 1.30, the color difference value between the two points with the smallest color difference on the two curves is 0.0055uv, and the color temperature range is 9000K~1000K , create spectroscopic X block (such as figure 1 shown) and the coordinate table TX corresponding to the block:

[0052]

[0053] Find the coordinates corresponding to the four vertices of all blocks within the X block range, and input them into the fully automatic spectrometer, which will measure and sort the LEDs, and assign the LEDs to different types. All the white LEDs in the X block will be sorted out.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com