Splicing type water permeable brick

A permeable brick, splicing technology, applied in the direction of roads, pavement details, side ditch/curbstone, etc., can solve the problems of loose brick body, unfavorable people walking, loss of permeable effect, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

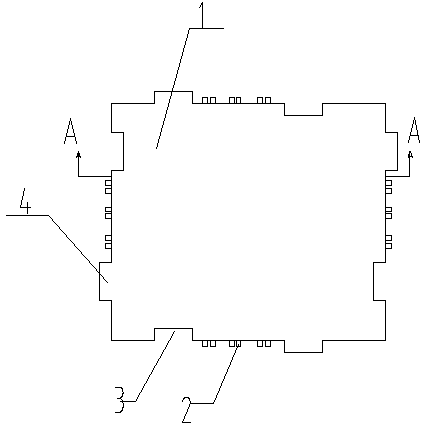

[0018] Such as figure 1 and figure 2 The spliced permeable brick includes a square base block 1, and a protrusion 4 and a groove 3 are respectively arranged on the four side walls of the square base block 1, and the protrusion The thickness of the block 4 is smaller than the thickness of the square base block 1, and the upper end surface of the bump 4 is flush with the upper end face of the base block 1; Bar 2, at least 2 sets of limiting bars 2 are arranged on each side wall. The protrusions 4 and the grooves 3 are equidistantly distributed on each side of the base block 1 , and the protrusions 4 and the grooves 3 are distributed at intervals between each side. And the two sides of each protrusion are respectively adjacent to two grooves, and the shape of the protrusion 4 and the groove 3 is preferably rectangular or V-shaped, which is convenient for splicing.

[0019] When in use, the protrusion on the side wall of each permeable brick base block is engaged with the gr...

Embodiment 2

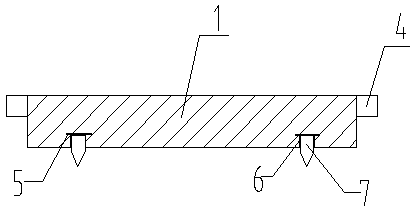

[0021] Different from Embodiment 1, in this embodiment, a support rod fixing sleeve 6 is embedded in the lower part of the base block 1, and the lower end surface of the support rod fixing sleeve 6 is flush with the lower end surface of the base block 1. , the fixed sleeve 6 is provided with an internal thread, and the fixed sleeve 6 is threadedly connected with a support rod 7 protruding from the fixed sleeve 6, and the upper end surface of the fixed sleeve 6 is fixed with a connecting piece 5, and the diameter of the connecting piece 5 is larger than The diameter of fixed sleeve 6. There are at least four support rod fixing sleeves on each base block, and the lowermost end of the support rod is a pointed structure.

[0022] In areas with large precipitation, or areas with large drainage needs, concrete can be laid on the foundation first, and then the support rods on the permeable bricks of this embodiment are embedded in the concrete layer and fixed, so that the water is pe...

Embodiment 3

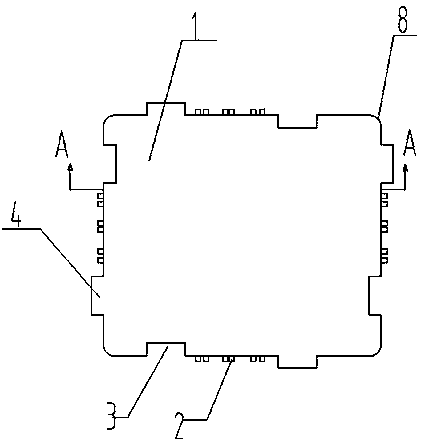

[0024] Such as image 3 As shown, the difference between this embodiment and Embodiment 2 is that the four corners of the base block are provided with arc-shaped chamfering 8 structures. By setting the chamfering structure, the gap between each permeable brick can be increased, and at the same time, it can also protect people from being scratched.

[0025] The invention provides a spliced permeable brick, which can be easily spliced and installed by adopting the form of bumps and grooves on the four sides of the base block, and can When each base block is spliced, the two adjacent base blocks are separated by a limit strip, so that there is a suitable gap between each base block, which is convenient for rainwater to penetrate through the gap, thereby reducing the area of the road surface. water; by making the thickness of the bump smaller than the thickness of the base block, there is still a certain gap between the bump and the foundation, which increases the drainage ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com