Column base structure of large-span steel structure trestle

A steel structure and long-span technology, applied in bridges, bridge parts, bridge materials, etc., can solve the problems of large impact on the central column of the stacker and fracture of the central column, so as to reduce the horizontal thrust, improve the service life, and not easily break Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

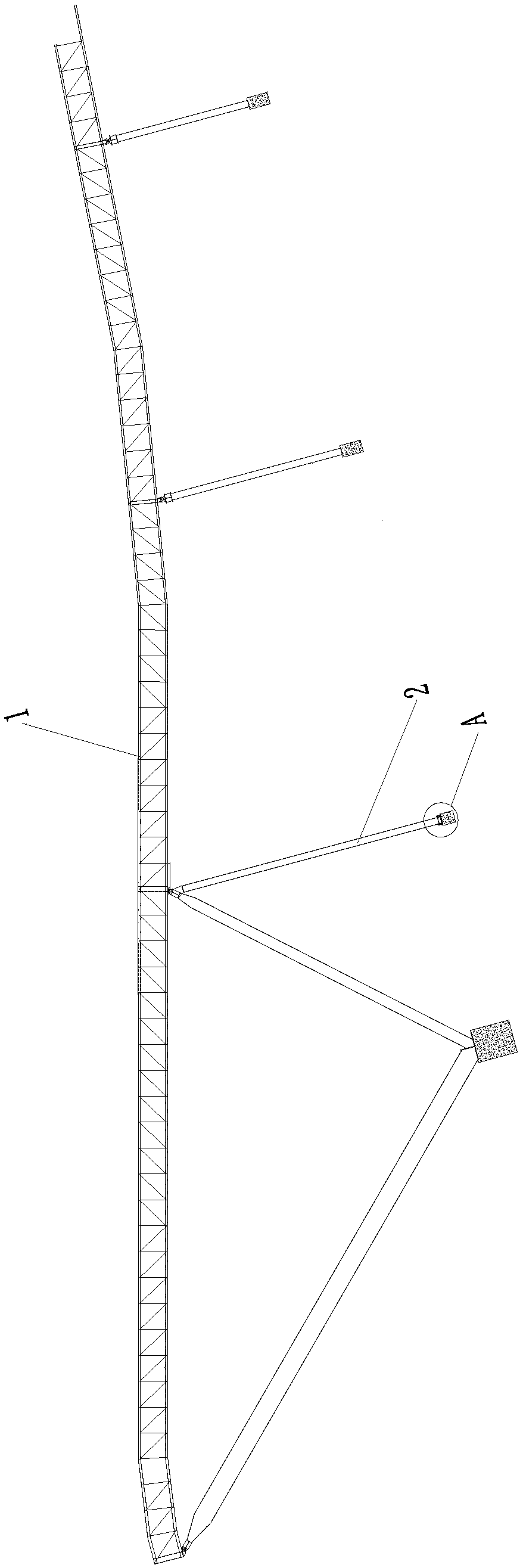

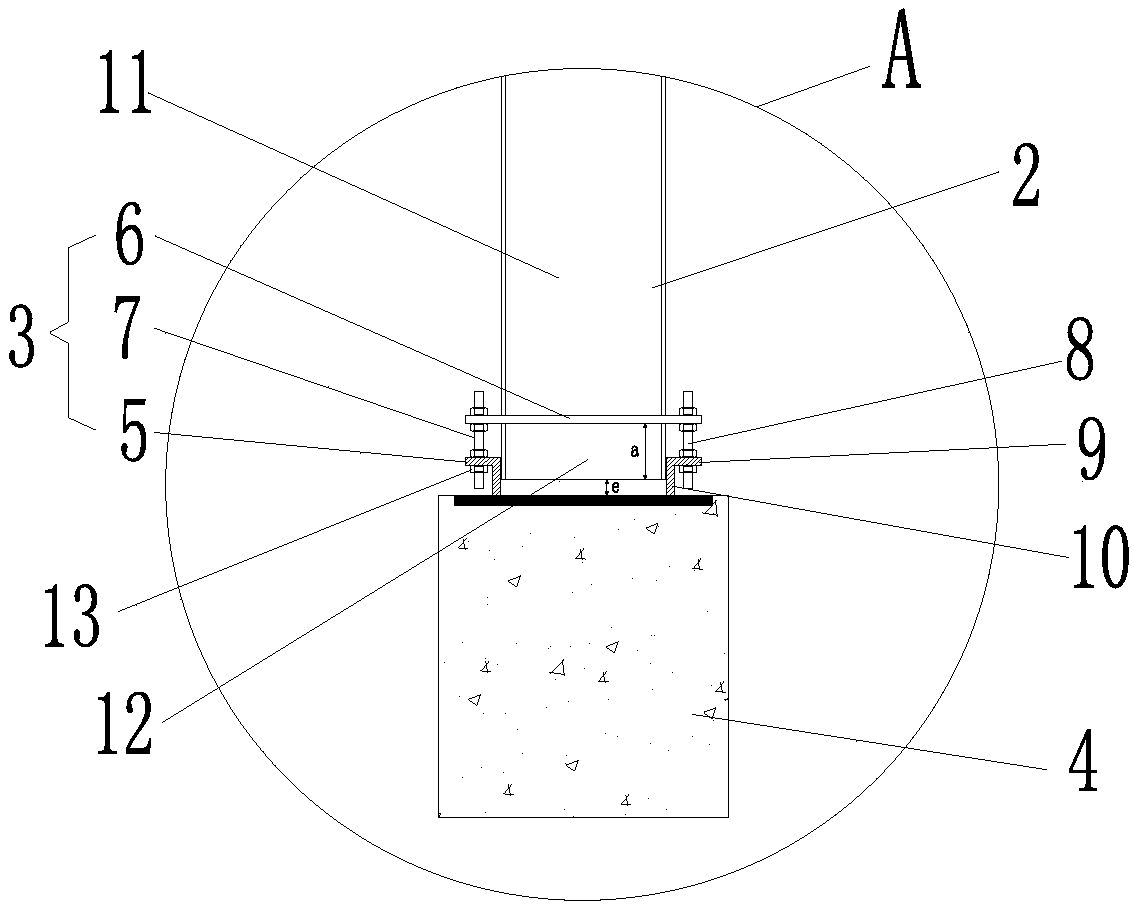

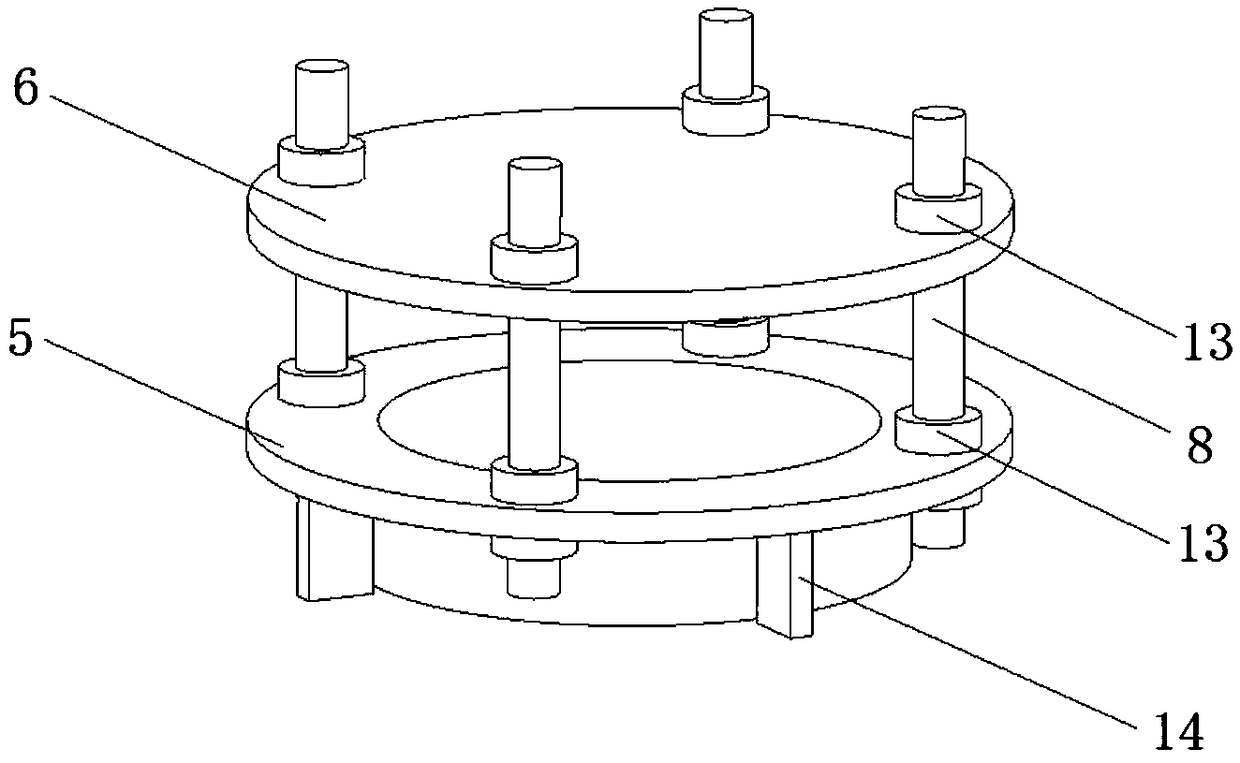

[0019] Embodiment 1: A column foot structure of a long-span steel structure trestle, including a steel structure trestle 1 and a column 2, the column 2 is arranged below the steel structure trestle 1, and is connected with the steel structure trestle 1; the bottom position of the column 2 A height adjustment device 3 is provided. The height adjustment device 3 is fixedly connected with the foundation embedded part 4. The height adjustment device 3 includes a positioning device 5, a column connecting plate 6 and a bolt adjustment assembly 7. The positioning device 5 is fixedly installed on the foundation embedded part 4. Above, the column connecting plate 6 is arranged above the positioning device 5, the bolt adjusting assembly 7 is arranged between the positioning device 5 and the column connecting plate 6, the bolt adjusting assembly 7 is connected with the positioning device 5, and the bolt adjusting assembly 7 is also connected with the column connecting plate 6 connections....

Embodiment 2

[0020] Embodiment 2: A column foot structure of a long-span steel structure trestle, including a steel structure trestle 1 and a column 2, the column 2 is arranged below the steel structure trestle 1, and is connected with the steel structure trestle 1; the bottom position of the column 2 A height adjustment device 3 is provided. The height adjustment device 3 is fixedly connected with the foundation embedded part 4. The height adjustment device 3 includes a positioning device 5, a column connecting plate 6 and a bolt adjustment assembly 7. The positioning device 5 is fixedly installed on the foundation embedded part 4. Above, the column connecting plate 6 is arranged above the positioning device 5, the bolt adjusting assembly 7 is arranged between the positioning device 5 and the column connecting plate 6, the bolt adjusting assembly 7 is connected with the positioning device 5, and the bolt adjusting assembly 7 is also connected with the column connecting plate 6 connections....

Embodiment 3

[0021] Embodiment 3: A column foot structure of a long-span steel structure trestle, including a steel structure trestle 1 and a column 2, the column 2 is arranged below the steel structure trestle 1, and is connected with the steel structure trestle 1; the bottom position of the column 2 A height adjustment device 3 is provided. The height adjustment device 3 is fixedly connected with the foundation embedded part 4. The height adjustment device 3 includes a positioning device 5, a column connecting plate 6 and a bolt adjustment assembly 7. The positioning device 5 is fixedly installed on the foundation embedded part 4. Above, the column connecting plate 6 is arranged above the positioning device 5, the bolt adjusting assembly 7 is arranged between the positioning device 5 and the column connecting plate 6, the bolt adjusting assembly 7 is connected with the positioning device 5, and the bolt adjusting assembly 7 is also connected with the column connecting plate 6 connections....

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com