Rotary rice drying system

A drying system, rotary technology, applied in the direction of drying, drying machine, non-progressive drying machine, etc., can solve the problems of low rice quality, failure to meet quality requirements, affecting rice export and foreign exchange earnings, etc. Achieve the effects of low drying cost, reduced horizontal thrust, and strong overload resistance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

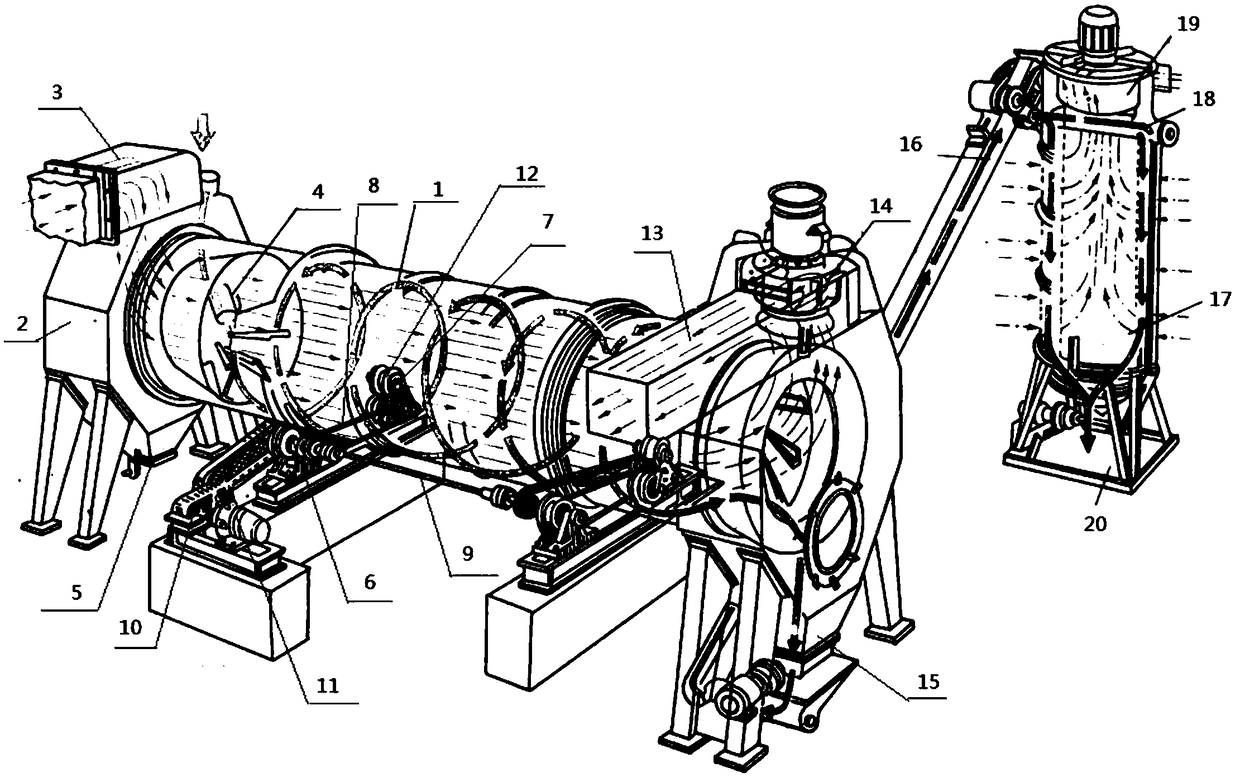

[0010] Example: see attached figure 1 , a rotary rice drying system, a drying drum 1 is arranged horizontally, the drying drum is provided with a left feed box 2 on the left side, and the left feed box is provided with a hot air inlet pipe 3 at the top, the The left feed box is provided with a drying drum docking hole on the right side, and a rice feed pipe 4 is also arranged in the left feed box, and the rice feed pipe is vertically arranged on the left feed box, And the lower end of the rice feed pipe extends to the inside of the drying cylinder, the left feed box is provided with a cleaning bin door 5 at the bottom, and the drying cylinder is provided with several oblique stirring plates on the inner cylinder wall, so that Described drying drum is provided with support frame at the bottom, and described support frame is all provided with first inner side support wheel 6, the first outer side support wheel 7 respectively at both sides of drying drum, and described first inne...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com