Structural design and construction method of a partially assembled subway station

A subway station, partial assembly technology, applied in the direction of basic structure engineering, underwater structures, artificial islands, etc., can solve the problems of uncoordinated deformation of columns and side walls, insufficient deformation capacity of columns, loss of vertical bearing capacity, etc., to achieve Improve the waterproof effect, the waterproof quality is easy, and the effect of improving the construction environment

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment

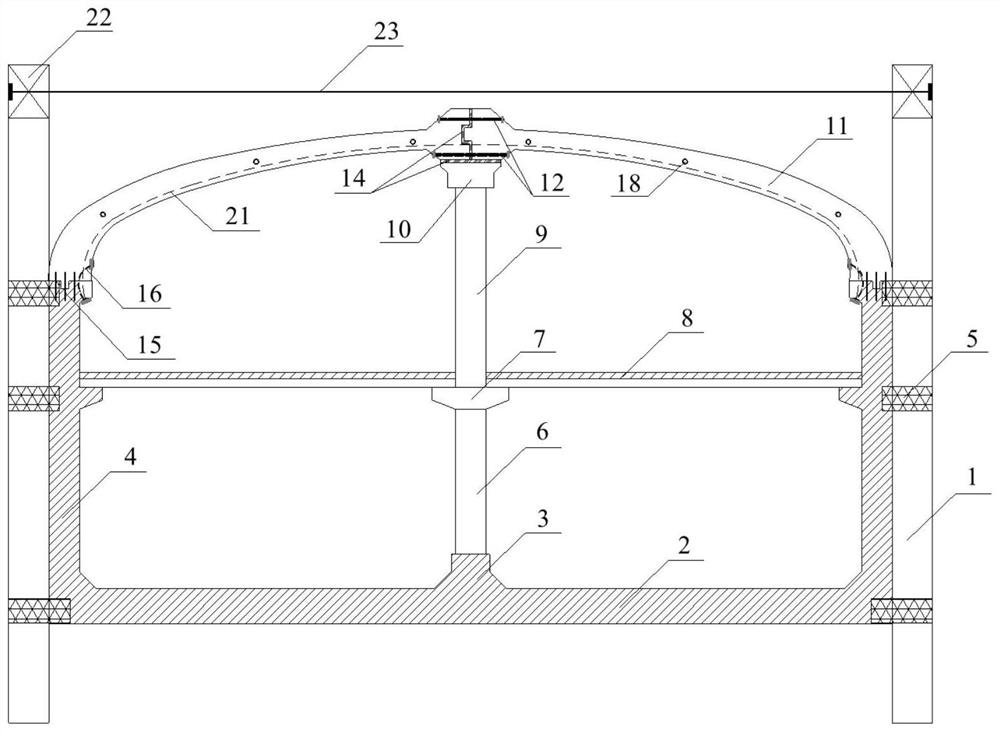

[0057] Step 1: Construction enclosure, leveling the site, constructing bored piles at equal intervals along the periphery of the foundation pit, pouring pile crown beams, excavating the foundation pit and supporting it in time.

[0058] Step 2: Apply the floor cushion. After the cushion is finally set, construct the waterproof layer and protective layer of the floor.

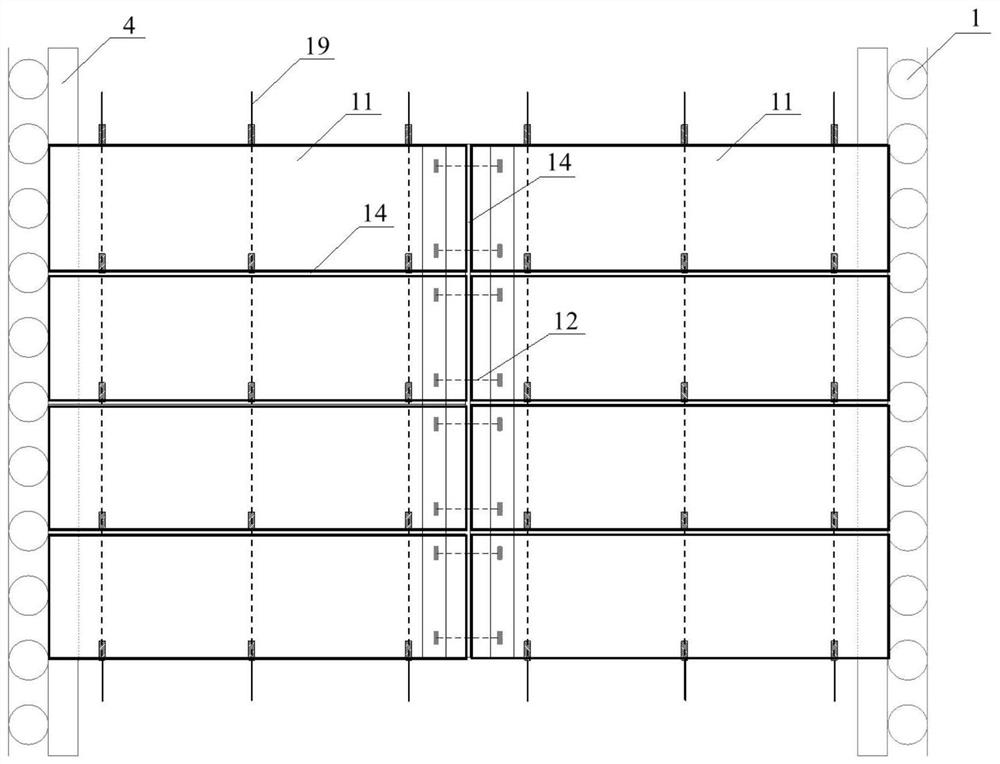

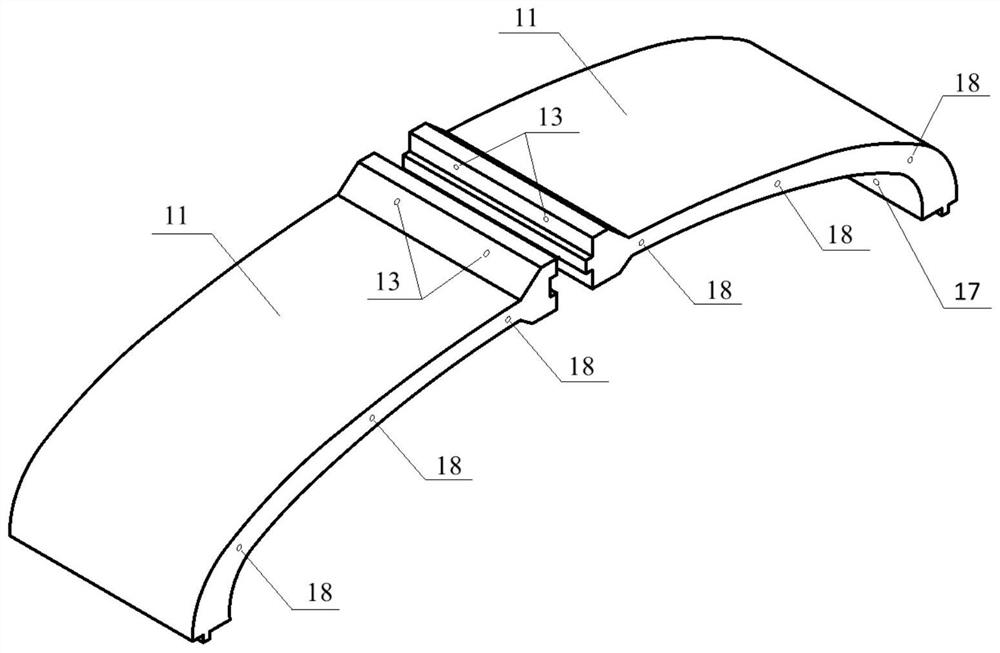

[0059] Step 3: Bind the bottom slab, bottom beam and side wall steel bars, and pour them on site separately. At the height of each floor slab, a reinforcement layer is set to connect the cast-in-place side wall and the bored pile, and the two are poured as one. Corbels are set at the joints between the cast-in-place side wall and the laminated middle plate and the prefabricated arched roof; the top surface of the cast-in-place side wall is provided with notches, reserved holes and extended longitudinal ribs for connecting the prefabricated arched roof.

[0060] Step 4: Assemble the prefabricated lower column, p...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com