Preparation technical equipment of continuous ceramic fiber and composite material thereof

A composite material and technical equipment technology, which is applied in the field of continuous ceramic fiber and composite material preparation technology equipment, can solve the problems of difficult operation, complex equipment structure, large volume, etc., and achieves easy cleaning and maintenance, simple equipment structure, and automation. high degree of effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

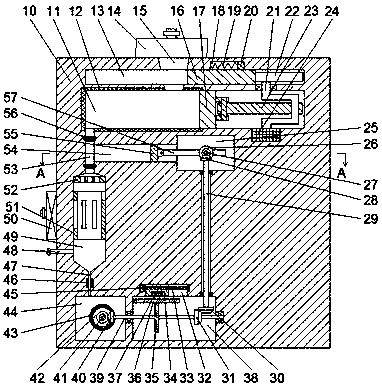

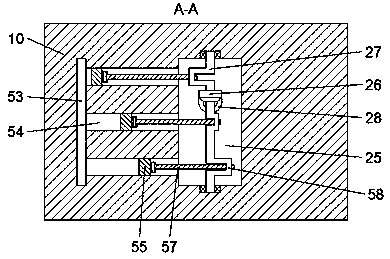

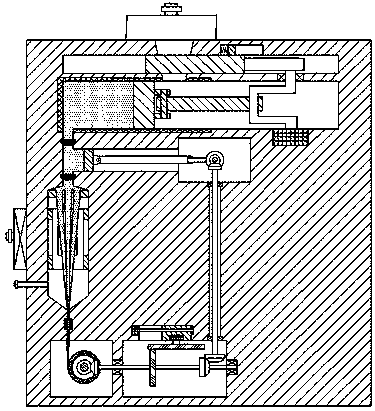

[0017] Such as Figure 1-Figure 3As shown, a kind of continuous ceramic fiber and its composite material preparation technical equipment of the present invention, comprise box body 10, described box body 10 is provided with first cavity 13, second cavity 11, the first cavity successively from top to bottom. Three cavity 25, the fourth cavity 49 and the fifth cavity 44, the fifth cavity 44 right end is provided with the sixth cavity 38, between the second cavity 11 and the fourth cavity 49 The first conveying groove 53 located at the left end of the third cavity 25 is communicated with the first conveying groove 53 and the third cavity 25 is communicated with three extruding passages 54 arranged uniformly. A second delivery groove 47 is communicated between the fourth cavity 49 and the fifth cavity 44, and a first guide slider 17 is slidably connected to the second cavity 11, and the first guide slider The right end of the block 17 is hingedly connected with a first connecting...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com