Steel belt uniform-speed edge-scraping equipment

A technology for edge scraping and steel strip, applied in metal processing equipment, measuring/indicating equipment, other manufacturing equipment/tools, etc., can solve problems such as temperature rise of scraping tool, affecting steel strip material, waste of resources, etc., to prevent Reduce scraping quality, ensure scraping quality and prolong service life

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

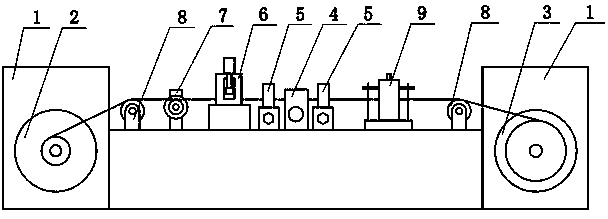

[0026] Example: see figure 1 , figure 2 , image 3 , Figure 4 , Figure 5 , Figure 6 , Figure 7 , Figure 8 , Figure 9 with Figure 10 , in the picture, 1-frame, 2-take-up pulley, 3-release pulley, 4-knife holder, 5-limiting wheel, 6-auxiliary wheel, 7-speed measuring roller, 8-guiding wheel, 9-leveling wheel;

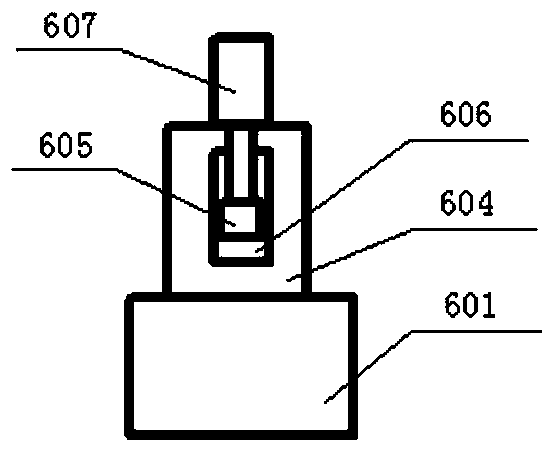

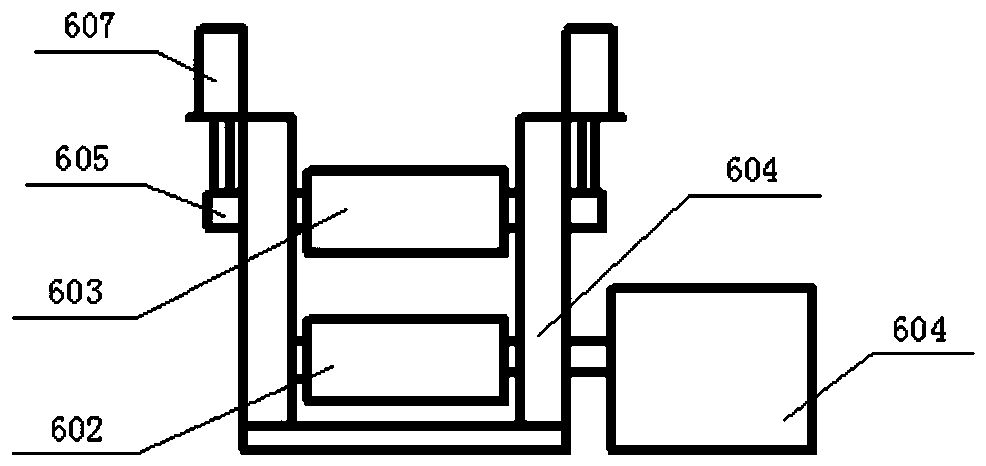

[0027] 601-auxiliary motor, 602-auxiliary wheel one, 603-auxiliary wheel two, 604-auxiliary bracket, 605-slider, 606-slide, 607-auxiliary cylinder;

[0028] 401-cutter head Ⅰ, 402-cutter head Ⅱ, 403-guide rail, 404-baffle plate, 405-moving handle;

[0029] 501-limiting wheel bracket, 502-removable limiting wheel, 503-limiting wheel bolt, 504-groove, 5021-detachable limiting wheel bracket, 5022-limiting wheel one, 5023-limiting wheel two;

[0030] 901-leveling wheel bracket, 902-bolt, 903-upper leveling wheel fixing plate, 904-upper leveling wheel, 905-lower leveling wheel, 906-adjusting bolt.

[0031] Steel belt uniform speed scraping equipment, includ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com