Casual inspection device for medicine filling glass bottle

A technology for glass bottles and medicine, which is applied in packaging, bottle filling, bottle cap pretreatment, etc. It can solve the problems of high cost, loose structure, and large floor space, and achieve the effect of low cost, compact structure, and rapid sampling inspection

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0019] The specific implementation manner of the present invention will be described in detail below in conjunction with the accompanying drawings.

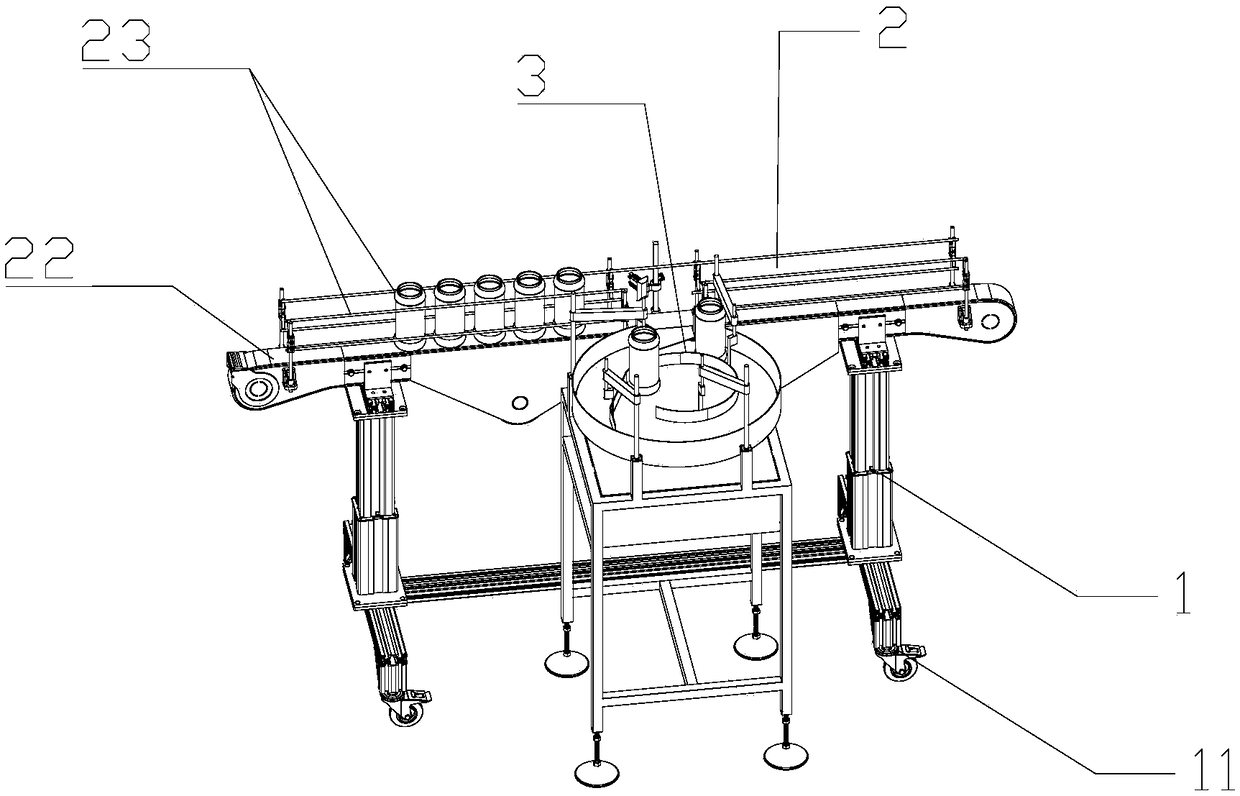

[0020] Such as figure 1 Shown is a medical filling glass bottle sampling device, the device includes a conveyor belt base 1, a glass bottle conveying device 2, a turntable sampling collection device 3, the glass bottle conveying device 2 is fixedly arranged on the conveyor belt base 1, The turntable sampling collection device 3 is connected with the glass bottle conveying device 2, and the glass bottles are transported from the glass bottle conveying device 2, and the glass bottles are pushed to the turntable sampling collecting device 3 at the joint to complete the collection of glass bottles.

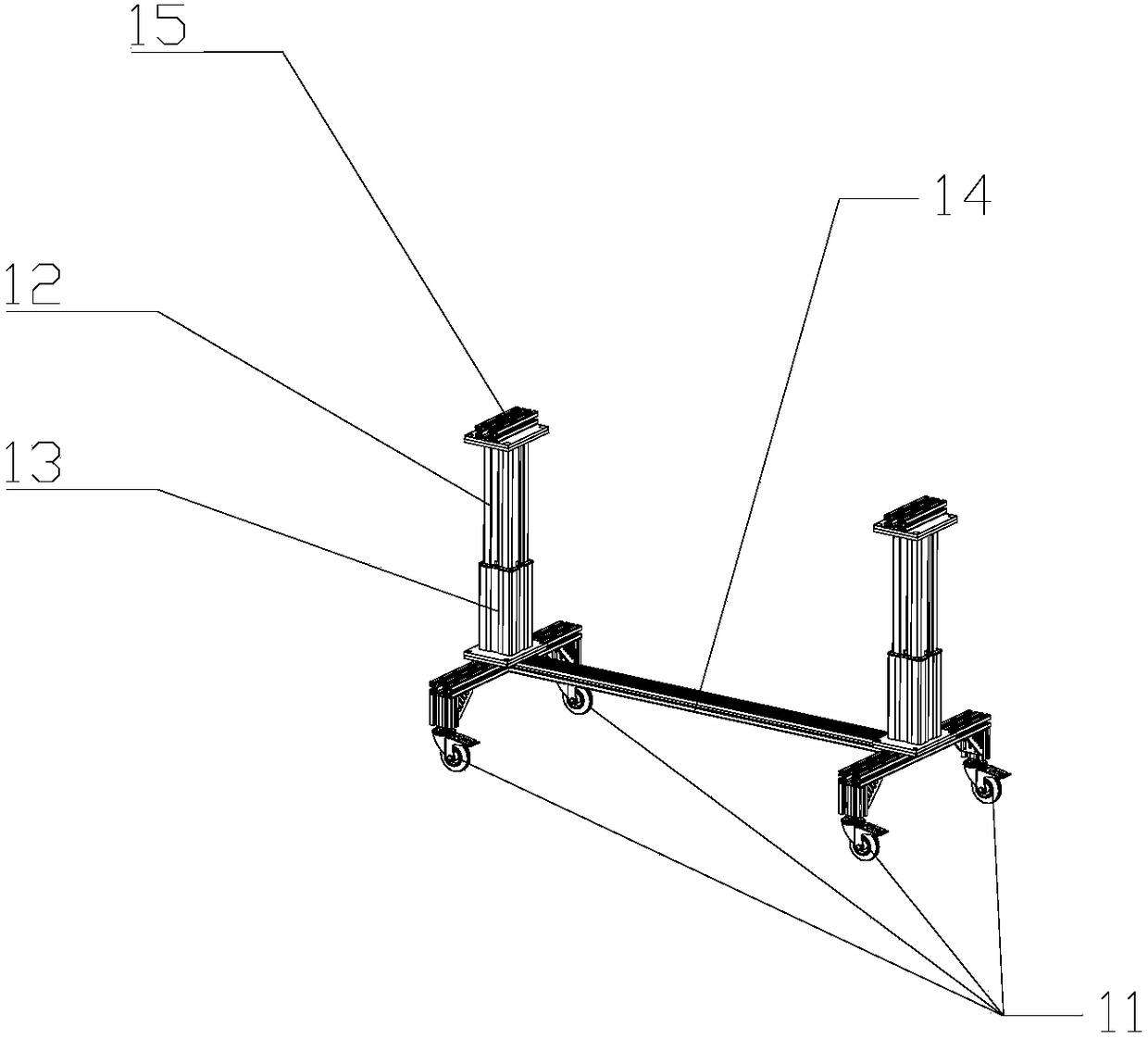

[0021] Such as figure 2 As shown, the conveyor belt base 1 includes a universal wheel 11, an embedded column 12, an outer column 13, a profile chassis 14, and a connection fixing plate 15, and the four universal wheels 11 are all fixed...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com