A Design Method of Uniform Flow Guide Components Based on Exhaust Duct Area Control

A technology of flow guide components and design methods, applied in geometric CAD, special data processing applications, etc., can solve problems such as uneven exhaust, and achieve the effect of avoiding debugging work and high adaptability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0043] The present invention is described in further detail below in conjunction with embodiment.

[0044] First, explain or define the terms involved:

[0045] Exhaust duct area control: Exhaust duct area control refers to the design of atlases in accordance with national regulations or relevant national building standards to determine the size of residential centralized flue and branch pipes.

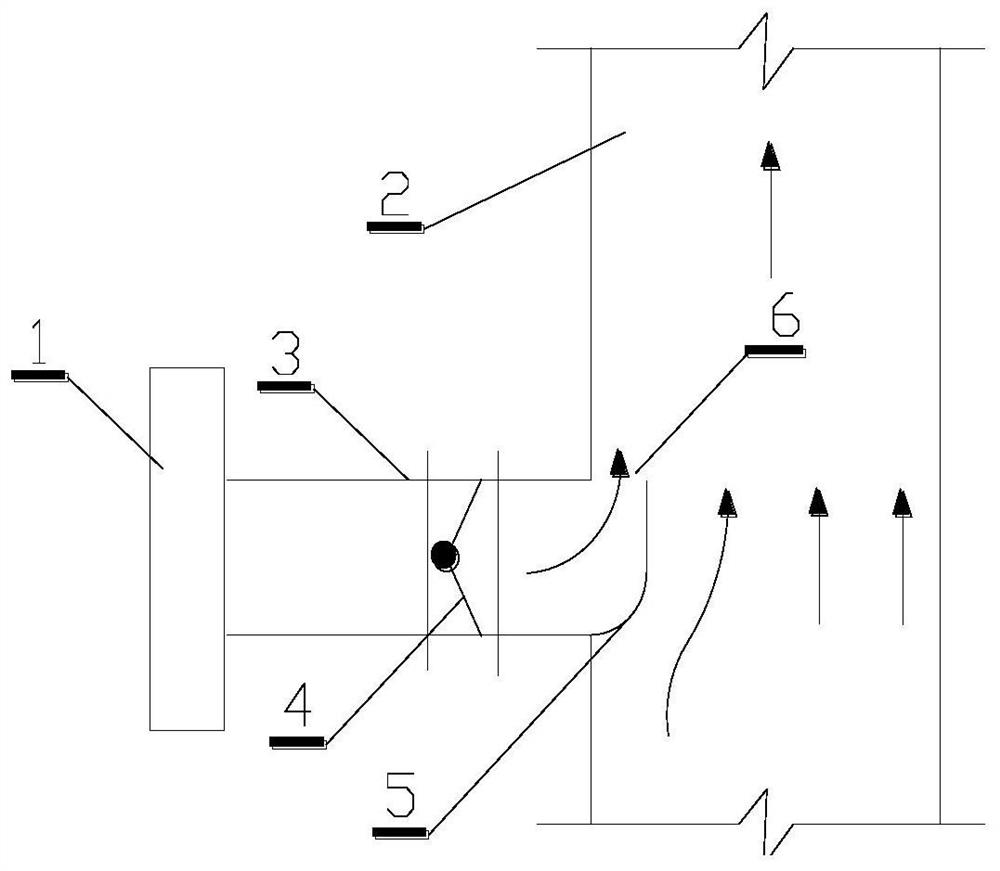

[0046] see figure 1 , is a schematic diagram of the installation position of a certain layer of flow guide members in the centralized air duct according to the embodiment of the present invention. It includes a range hood 1, an exhaust duct 2, a user branch pipe 3, a check valve 4, and a flow guide member 5; the range hood 1 and the exhaust duct 2 are connected through the user branch pipe 3, so that the oil fume absorbed by the range hood passes through the branch pipe, exhaust The air duct is discharged, and the check valve 4 is installed on the user branch pipe 3 to prevent the o...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com