A control system based on two-story lift and traverse parking equipment

A technology of parking equipment, lifting and traversing, applied in the direction of comprehensive factory control, comprehensive factory control, electrical program control, etc., can solve the problems of long construction period and complex on-site wiring, reduce workload and avoid repetitive hardware design. effect of work

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

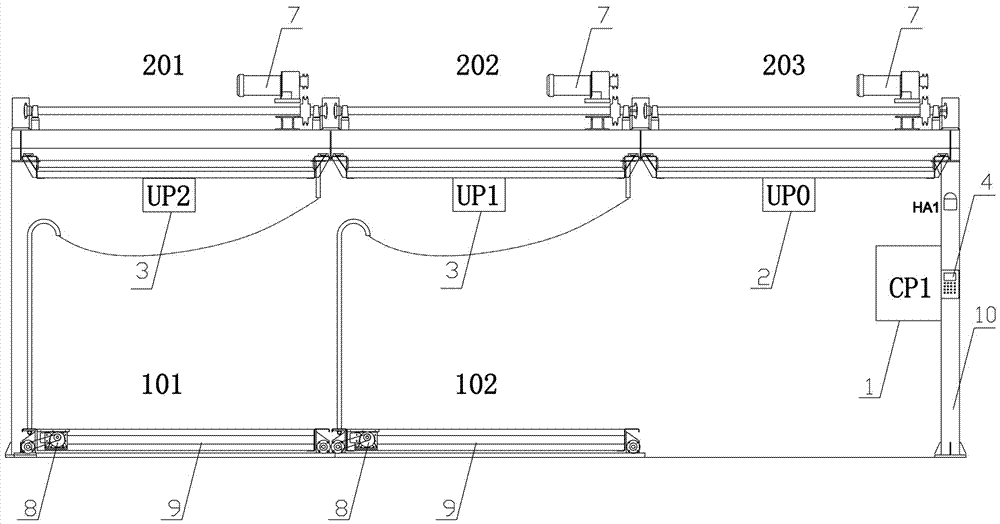

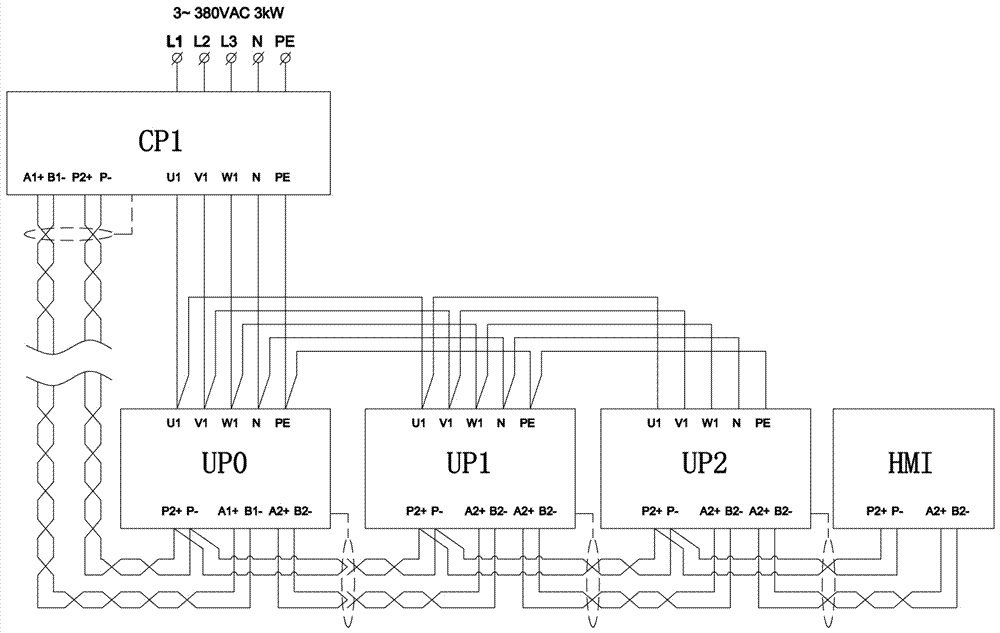

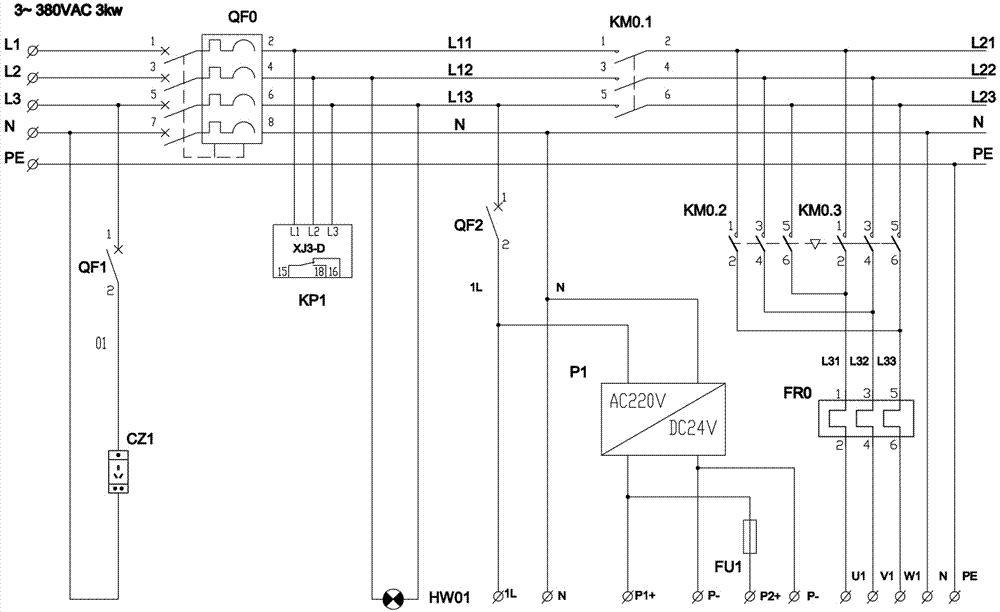

[0040] This embodiment describes the control system of the present invention by taking 1-row, 3-row, 2-floor lifting and traversing parking equipment as an example.

[0041] see figure 1 , 1-row, 3-column, 2-floor lifting and traversing parking equipment has 5 mechanical parking units to form a three-dimensional garage complex with 1 row, 3 columns, and 2 floors. Each mechanical parking unit corresponds to a parking space. The bottom parking spaces of the parking equipment are 101 parking spaces and 102 parking spaces, and there is an empty parking space on the right side of the 102 parking spaces. The upper parking spaces are 201 parking spaces and 202 parking spaces directly above the empty parking spaces. and 203 parking spaces, each mechanical parking unit includes a vehicle-carrying plate 9 arranged in each parking space and corresponding drive motors and detection components, wherein the vehicle-carrying plate 9 at the bottom of the parking equipment can only move latera...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com