Round wire L-shaped locking connector and connection method thereof

A technology of connectors and round wires, which is applied in the field of round wire L-shaped locking connectors and their connections, and can solve the problem of relatively large differences in the linear expansion coefficients between wire connectors and wires, small contact areas between wires and connectors, and wire bolts. Problems such as plastic deformation at the crimping point, to avoid electrochemical reactions, improve connection reliability, and increase the effect of connection contact area

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

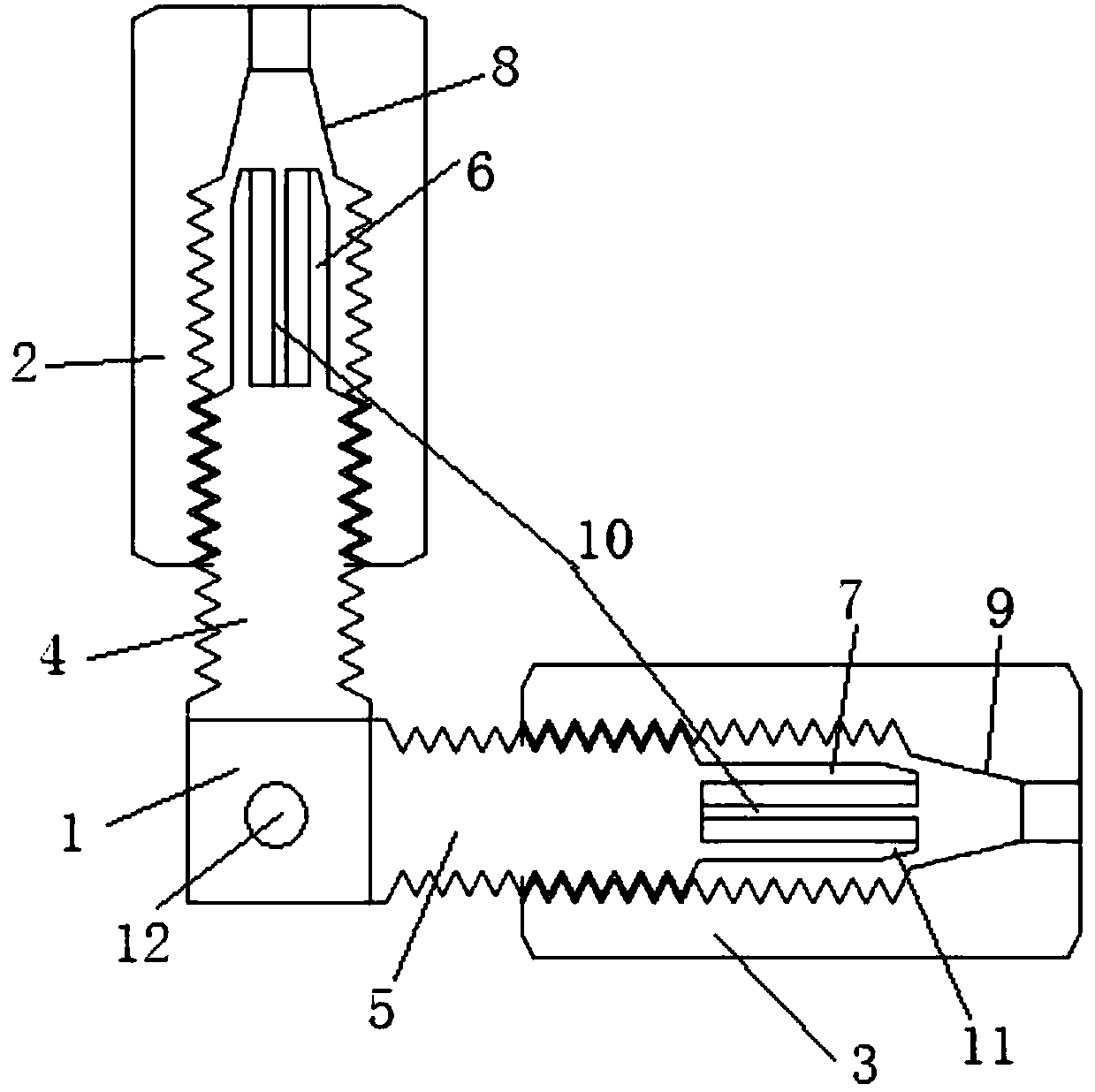

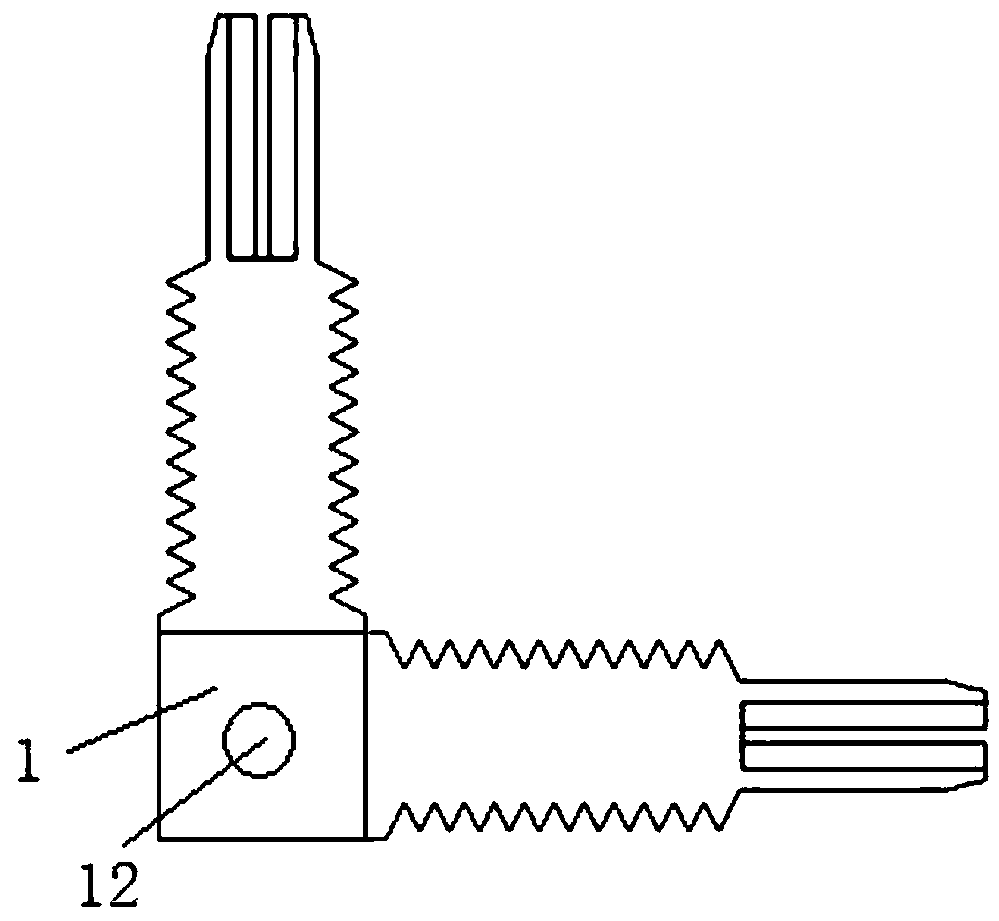

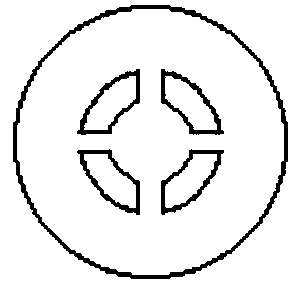

[0063] Embodiment 1: as Figure 1-Figure 8As shown, an L-shaped locking connector for round wires includes a conductive connecting body 1, an input locking nut 2 and an output locking nut 3, and the two ends of the connecting body 1 are respectively provided with mutually perpendicular input screw parts 4 and The output screw part 5, the ends of the input screw part 4 and the output screw part 5 are respectively provided with an input locking tube 6 and an output locking tube 7, and the inner holes of the outer ends of the input locking nut 2 and the output locking nut 3 are respectively provided There are input locking cone section 8 and output locking cone section 9, both input locking tube 6 and output locking tube 7 are provided with U-shaped opening 10, input locking nut 2 and output locking nut 3 are respectively connected to On the input screw part 4 and the output screw part 5, the input locking cone segment 8 and the output locking cone segment 9 are respectively sque...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com