Fixture device for processing the lower outlet seat of the solid-sealed pole on the ordinary machine tool

A technology for solid-sealing poles and fixture devices, applied in positioning devices, manufacturing tools, metal processing equipment, etc., can solve the problem that the dimensional accuracy of the lower outlet seat does not meet the requirements, affect the conductivity of the solid-sealing pole resistance loop, and increase the manufacturing process. Cost and other issues, to achieve the effect of improving product processing quality, simple structure, and reducing manufacturing and processing costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

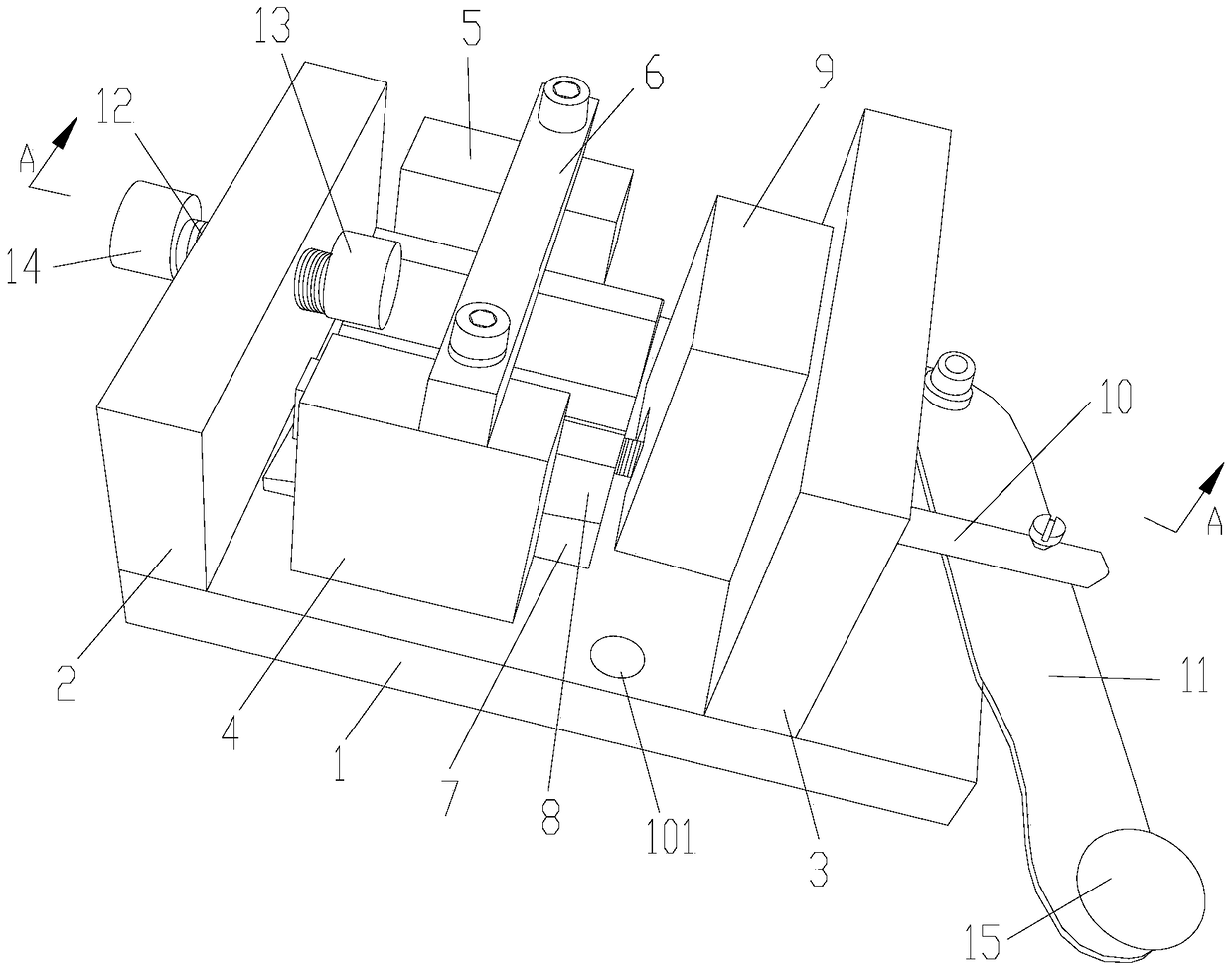

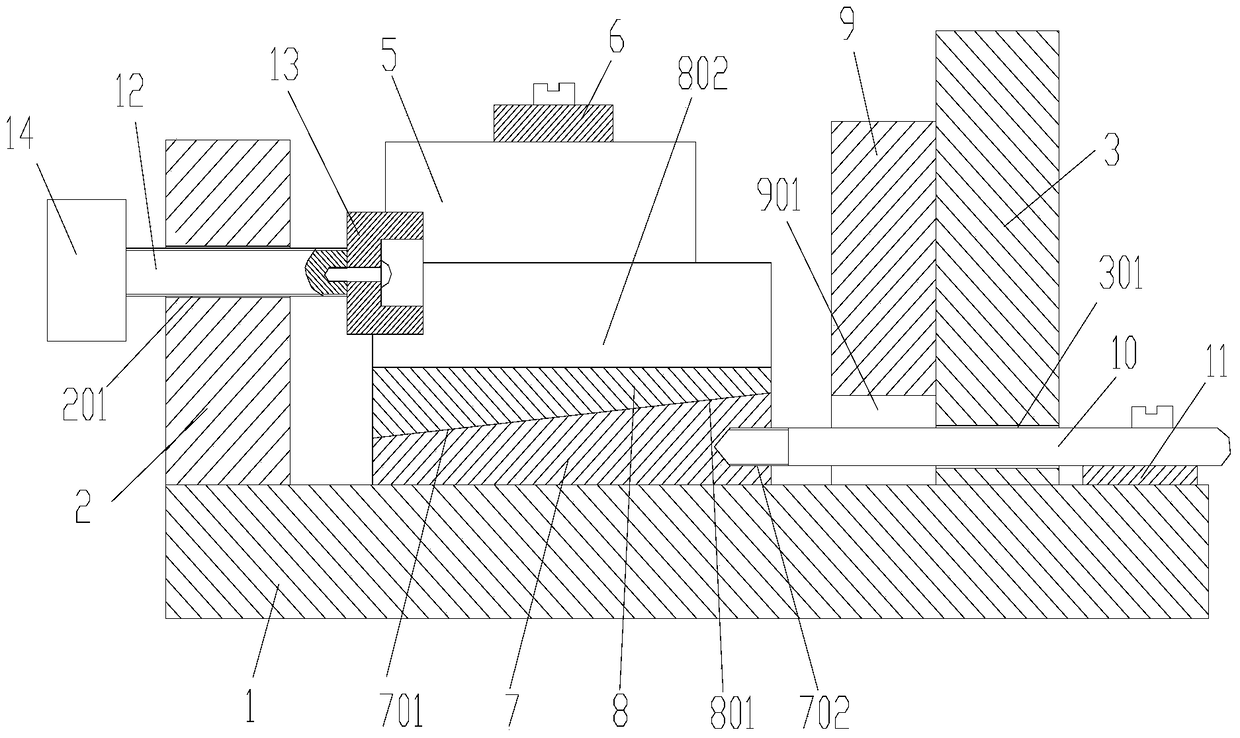

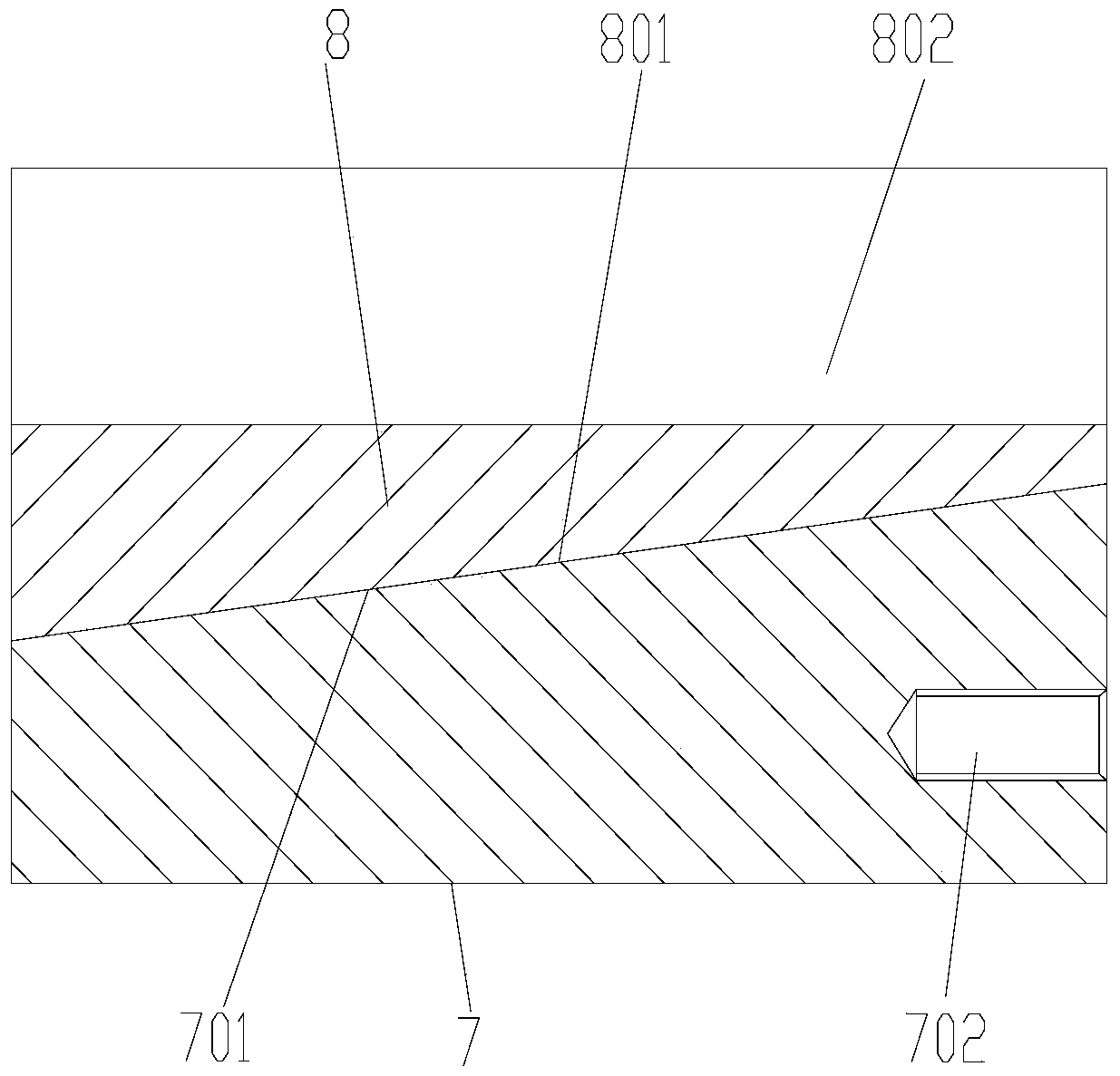

[0023] Attached below Figure 1-7 Embodiments of the present invention are described.

[0024] The fixture device used for processing the lower outlet seat of the solid-sealed pole on the ordinary machine tool, such as figure 1 and 2 As shown, it includes a bottom plate 1 fixedly connected with the working table of the machine tool, and the bottom plate 1 is provided with bolt connection holes 101 . One end of the upper end surface of the bottom plate 1 is vertically provided with a front plate 2, and the front plate 2 is provided with a front tightening assembly for horizontally and axially tightening the lower outlet seat 16. Specifically, the front tightening assembly includes a screw 12 and top tight block 13, the middle part of the front plate 2 is provided with a screw hole 201, the screw 12 is screwed with the screw hole 201, one end of the inner side of the screw 12 is fixed with a top tight block 13, the screw 12 One end of the outer side is provided with a rotati...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com