Control method of garbage crusher for water tank dish-washing machine

A control method and breaker technology, applied in the automatic detection under the control of the tableware washing machine/rinsing machine, tableware washing machine/rinsing machine, tableware washing machine/rinsing and rinsing machine parts, etc., can solve the problem of increasing labor intensity, Sink dishwasher damage, affecting user experience and other issues, to achieve the effect of small and compact structure and strong versatility

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0038] The present invention will be further described below in conjunction with the accompanying drawings and specific embodiments.

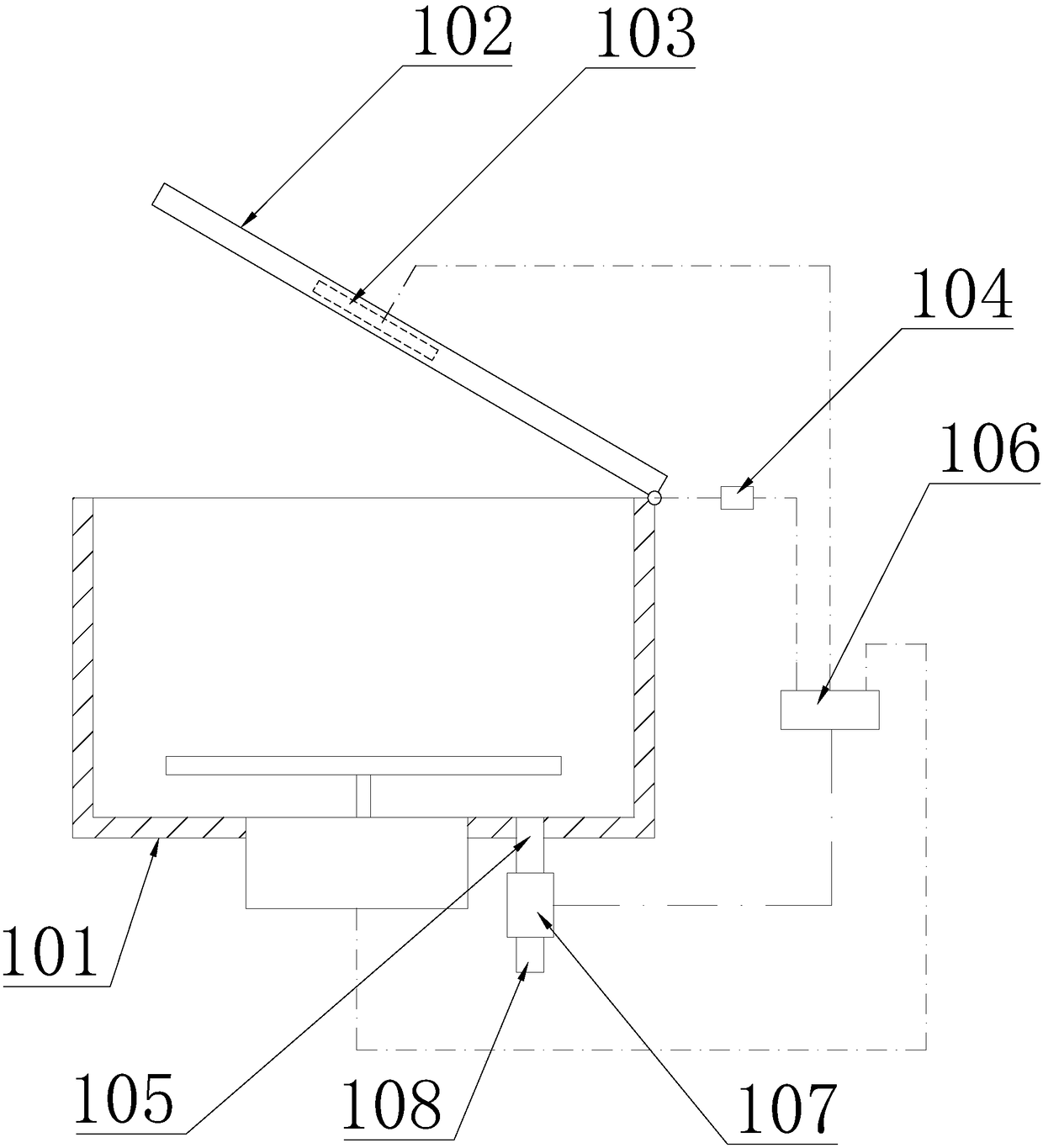

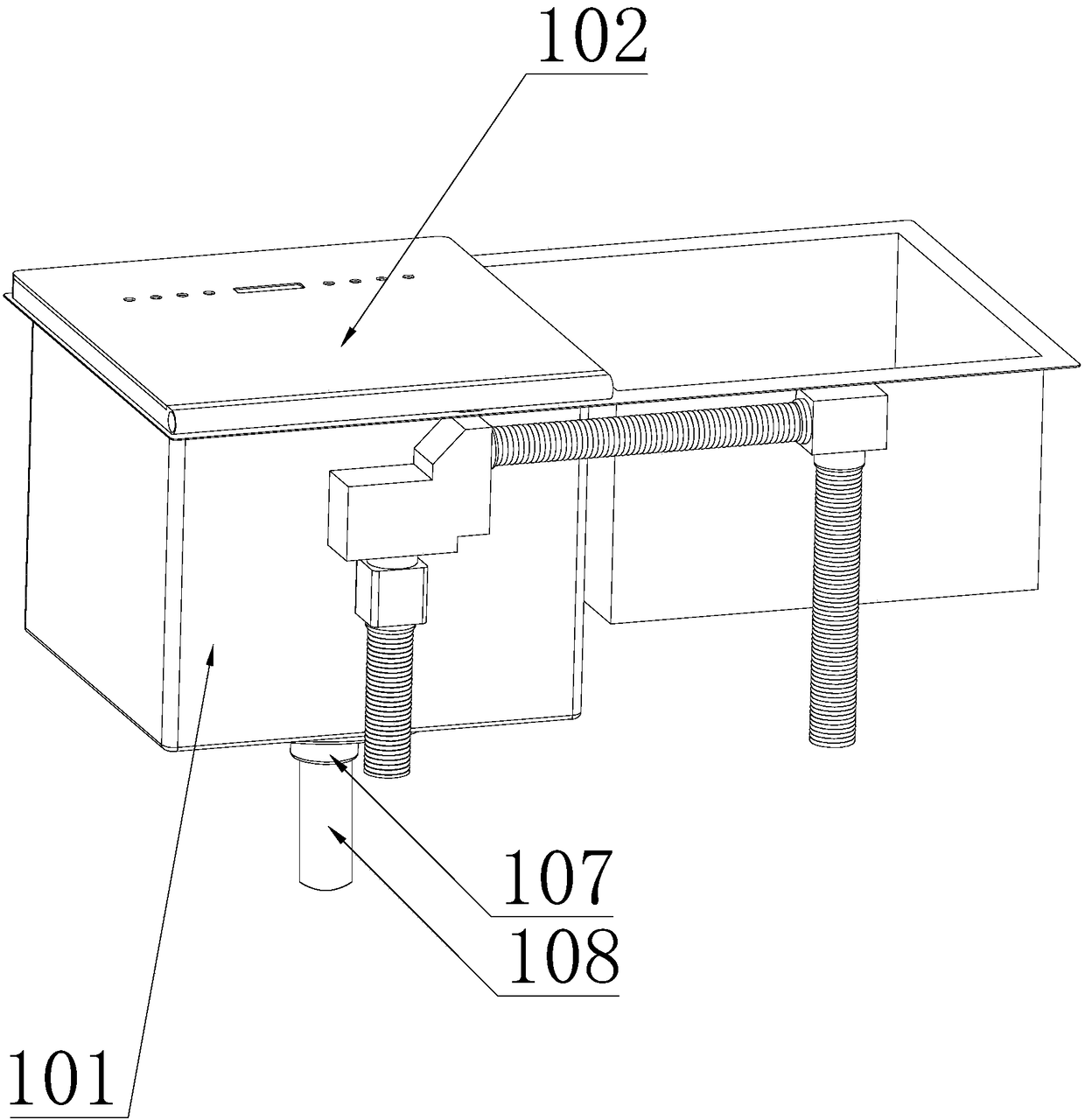

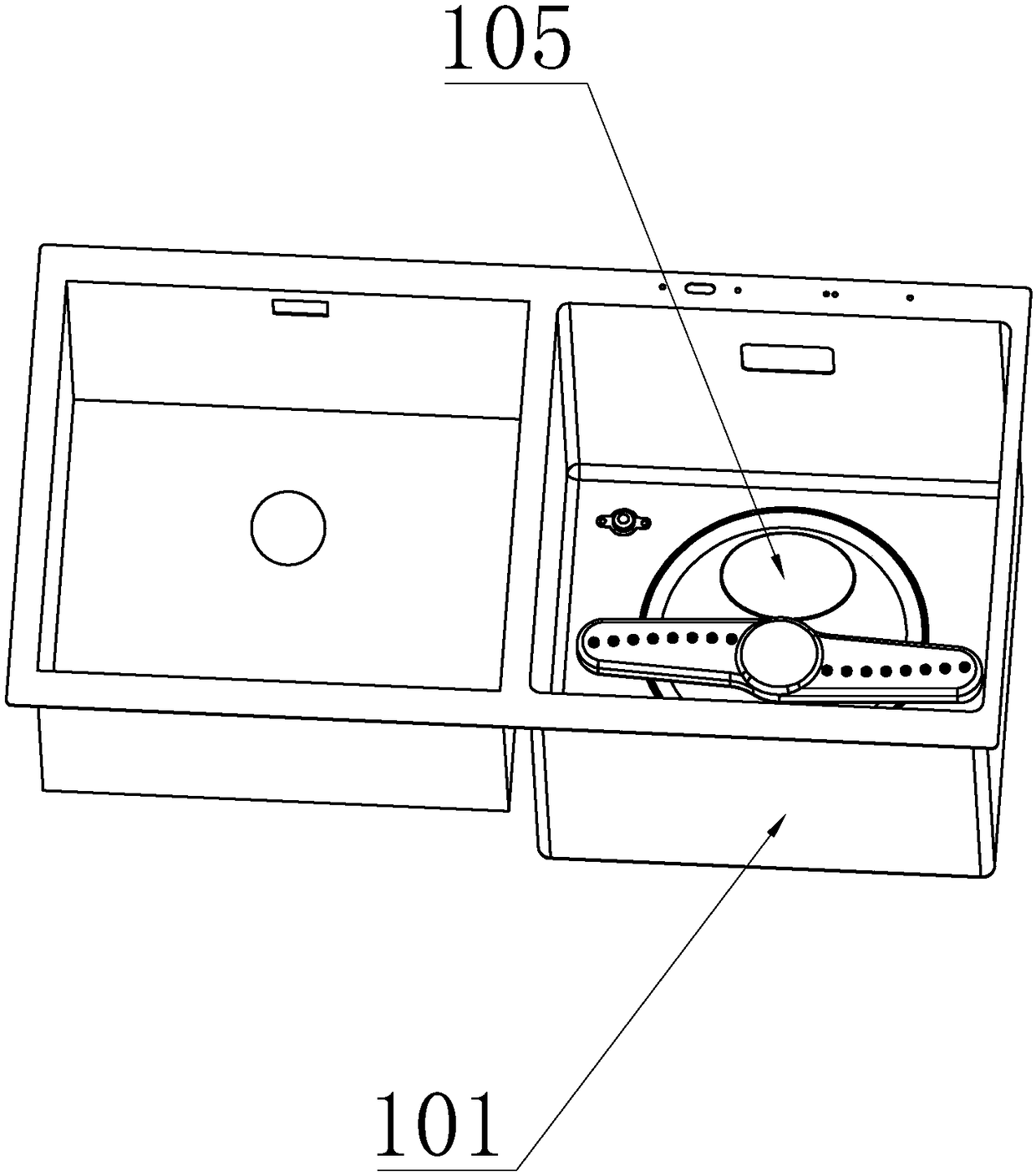

[0039] The present invention provides a control method for a garbage breaker used in a sink dishwasher, which includes a sink 101, a cover plate 102 is covered above the sink 101, and an operation panel 103 is arranged on the cover plate 102. The sink 101 is provided with a first sensor 104 for detecting the opening and closing of the cover plate 102. A drainer 105 and a controller 106 are installed at the bottom of the sink 101. The drainer 105 is provided with a garbage crushing device. The garbage breaker 107 includes a cylinder body 1 with pipe joints at both ends. The upper end of the cylinder body 1 communicates with the sink 101 through the drainer 105. A blade group 4, an impeller 5 and a stirring rod group 6 are provided in sequence, and the control method also includes the following steps:

[0040] S1. Close the cover plate 102, and ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com