Miniature pressure differential precipitation separation device

A technology of sedimentation separation and differential pressure, which is applied in the direction of sedimentation separation, feeding/discharging device of settling tank, separation method, etc. It can solve the risk of increasing sample contamination, disturb or destroy the sedimentation interface, and increase liquid removal Tools and other issues to achieve the effect of reducing the risk of secondary pollution, conducive to environmental protection, and improving experimental efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

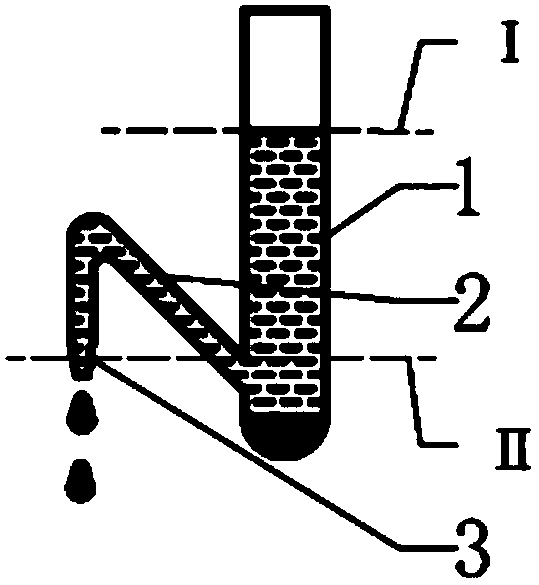

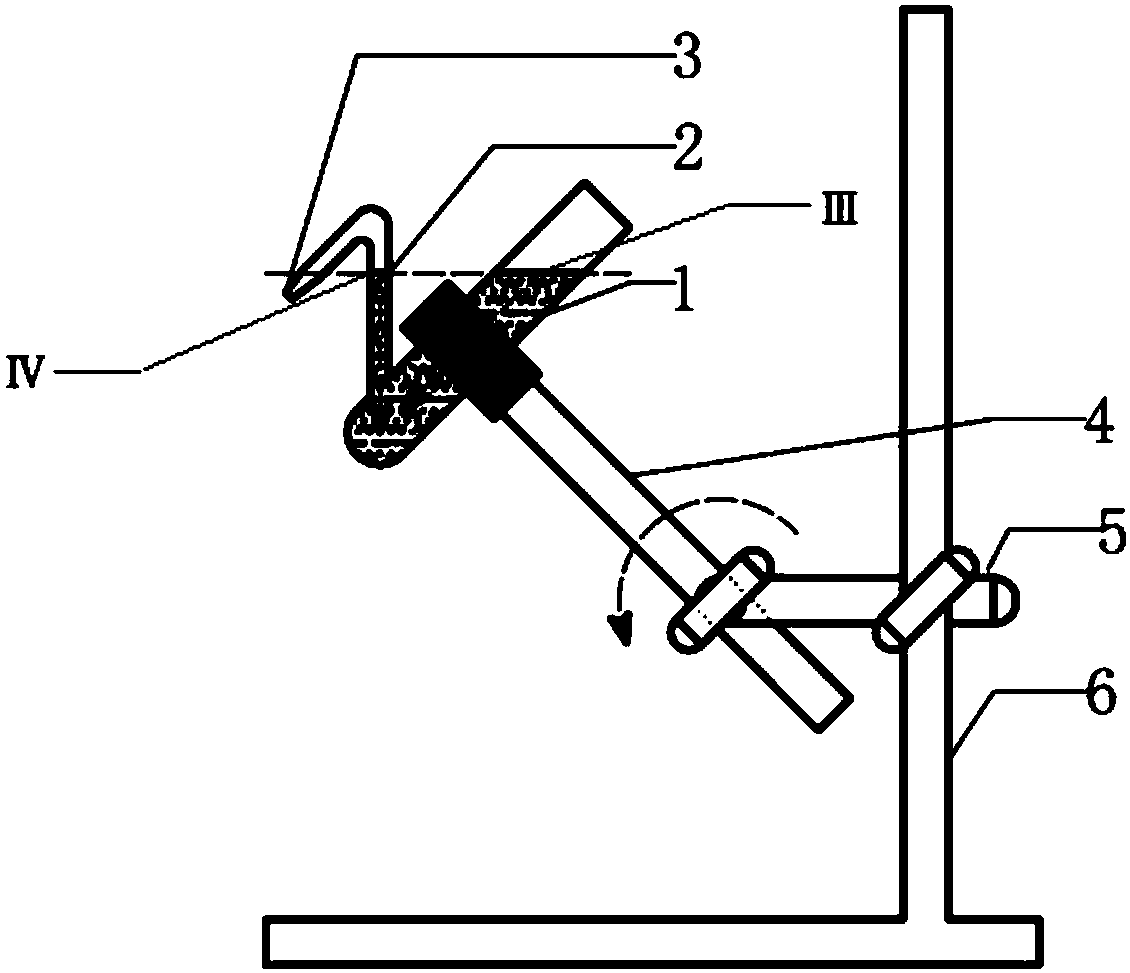

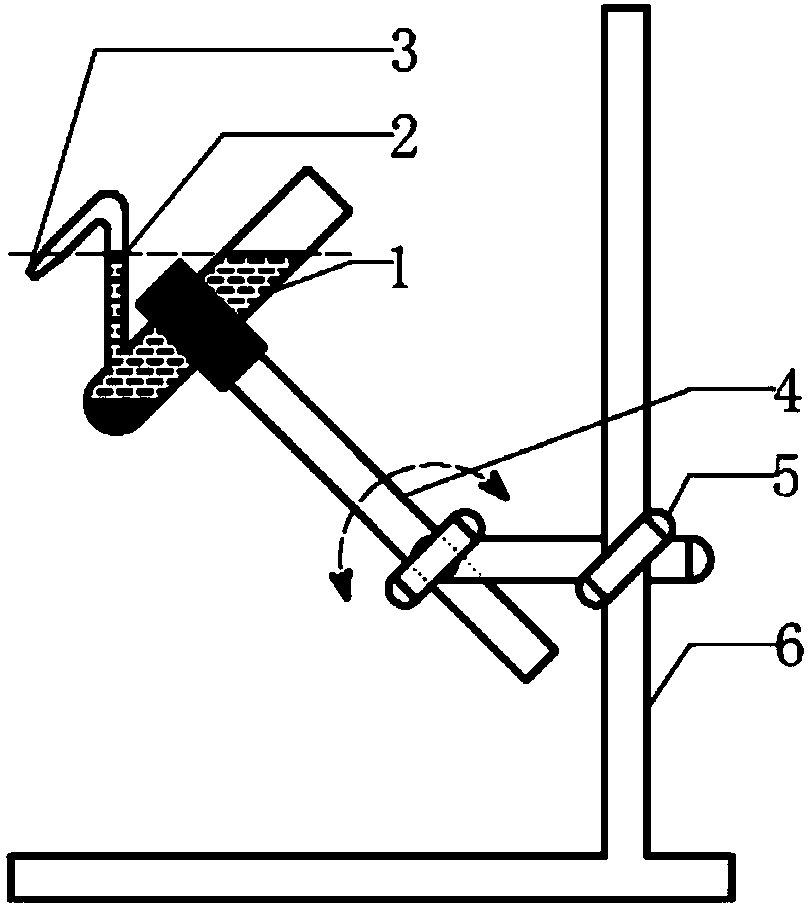

[0020] like Figures 1 to 3 As shown, a micro-pressure differential precipitation separation device includes a settling tube assembly and a settling tube holder. The settling set includes a settling tube 1, a manifold 2 and a dripper 3. Above the settling tube 1 is a One end of the manifold 2 communicates with the side of the sedimentation pipe 1, and the other end connects with the dripper 3. Manifold 2 is a bent pipe drawn from the side wall of sedimentation pipe 1. The angle ∠A between manifold 2 and sedimentation pipe 1 is 60°. Manifold 2 has a bend. The angle at this bend ∠B=∠ a. The diameter of the manifold 2 is smaller than that of the settling pipe 1; the diameter of the dripper 3 is smaller than that of the manifold 2. The connection between the manifold 2 and the settling pipe 1 is located at 1 / 5 of the bottom of the settling pipe 1 upward. When the settling tube 1 is placed vertically, the intersection point of the manifold 2 and the settling tube 1 is on the sam...

Embodiment 2

[0028] The included angle ∠A between the manifold 2 and the sedimentation pipe 1 is 30°, and the connection between the manifold 2 and the sedimentation pipe 1 is located at 1 / 2 of the bottom of the sedimentation pipe 1. All the other are with embodiment 1.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com