Bionic structure for long-distance spontaneous directional transmission of liquid drops and processing method of bionic structure

A technology of directional transmission and processing methods, applied in chemical instruments and methods, laboratory containers, laboratory utensils, etc., can solve the problem of smaller transmission droplets

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

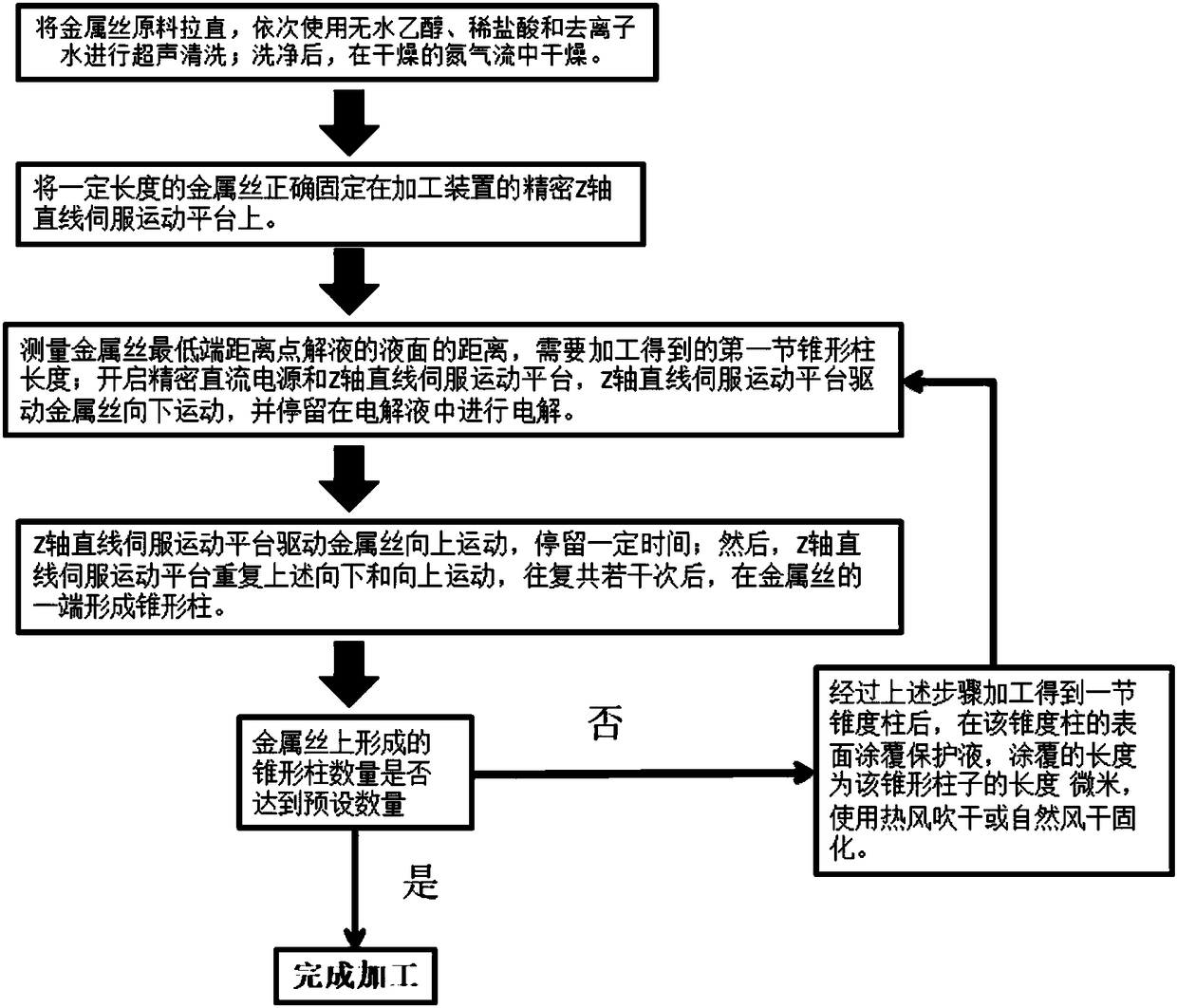

[0025] The technical solutions of the present invention will be further described below in conjunction with the accompanying drawings and through specific implementation methods.

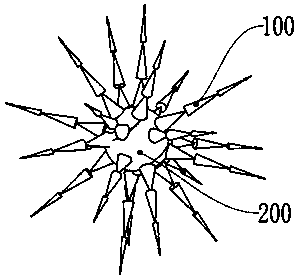

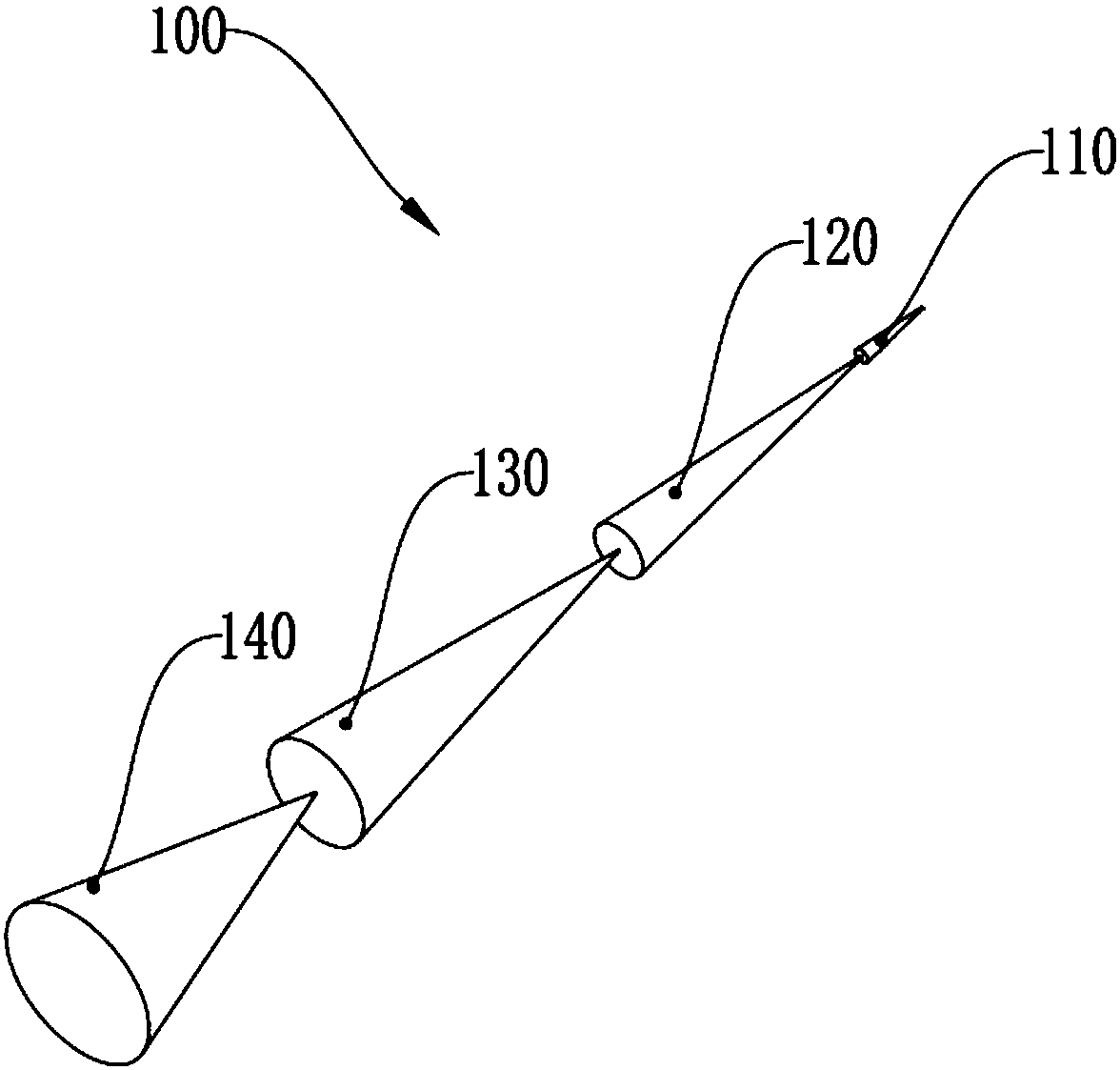

[0026] Such as figure 1 and 2 As shown, a biomimetic structure for long-distance spontaneous directional transport of droplets, which includes a mount body 200 and a conical spine 100 composed of four conical columns, the four conical columns are sequentially from the tip to the bottom of the conical thorn 100 It is: the first conical column 110, the second conical column 120, the third conical column 130, and the fourth conical column 140; the conical columns are connected end to end and coaxially arranged to form a strip-shaped cone Shaped thorns 100; the apex angles and lengths of a plurality of conical columns of the conical thorns 100 gradually increase along the direction from the apex to the bottom of the conical thorns 100; a plurality of the conical thorns 100 are uniform Fixed on the sur...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com