Crushing plant for substrates of waste printed circuit boards

A technology for waste circuit boards and crushing devices, applied in grain processing and other directions, can solve the problems of difficult crushing operation, incomplete crushing, etc., and achieve the effects of convenient and fast crushing operation, good crushing effect, and simple and effective structure.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0021] The following descriptions are only preferred embodiments of the present invention, and do not limit the scope of the present invention.

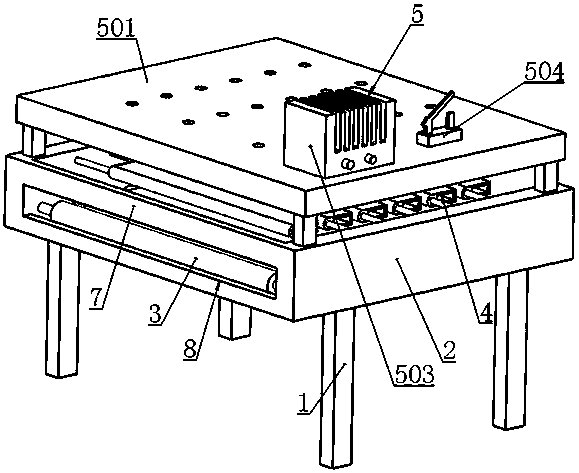

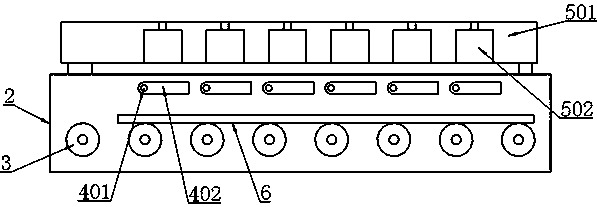

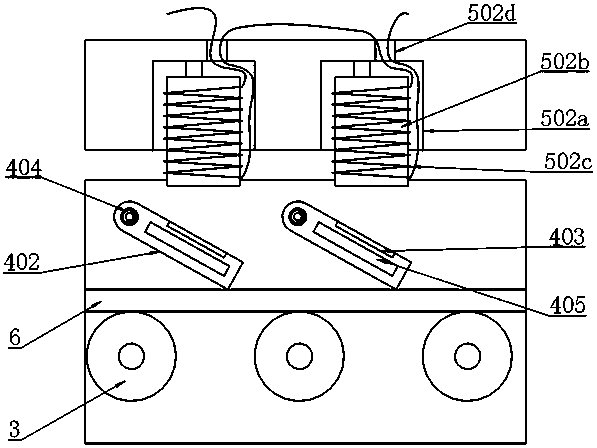

[0022] Example: as attached figure 1 , 2 , 3 and attached Figure 4 As shown, a crushing device for waste circuit board substrates includes a column 1, two mounting plates 2 arranged on the column 1, two rollers 3 respectively arranged on the two mounting plates 2 at both ends, rotating A crushing unit 4, and a magnetic drive unit 5 arranged on the mounting plate 2 and used to drive the rotary crushing unit 4 downward through magnetic repulsion, the rotary crushing unit 4 is arranged between the roller 3 and the between the magnetic drive units 5 .

[0023] In this embodiment, the substrate 6 is pushed onto the roller 3, and then the magnetic drive unit 5 generates a suitable and sufficient magnetic force to repel the rotation of the rotary crushing unit 4 and "hit" the substrate downward. 6. The purpose of crushing is achieved b...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com