Crushing process for building materials

A technology for building materials and processes, applied in the field of crushing technology for building materials, can solve problems such as low efficiency of crushing process, and achieve the effect of improving crushing effect, increasing efficiency and solving low production efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

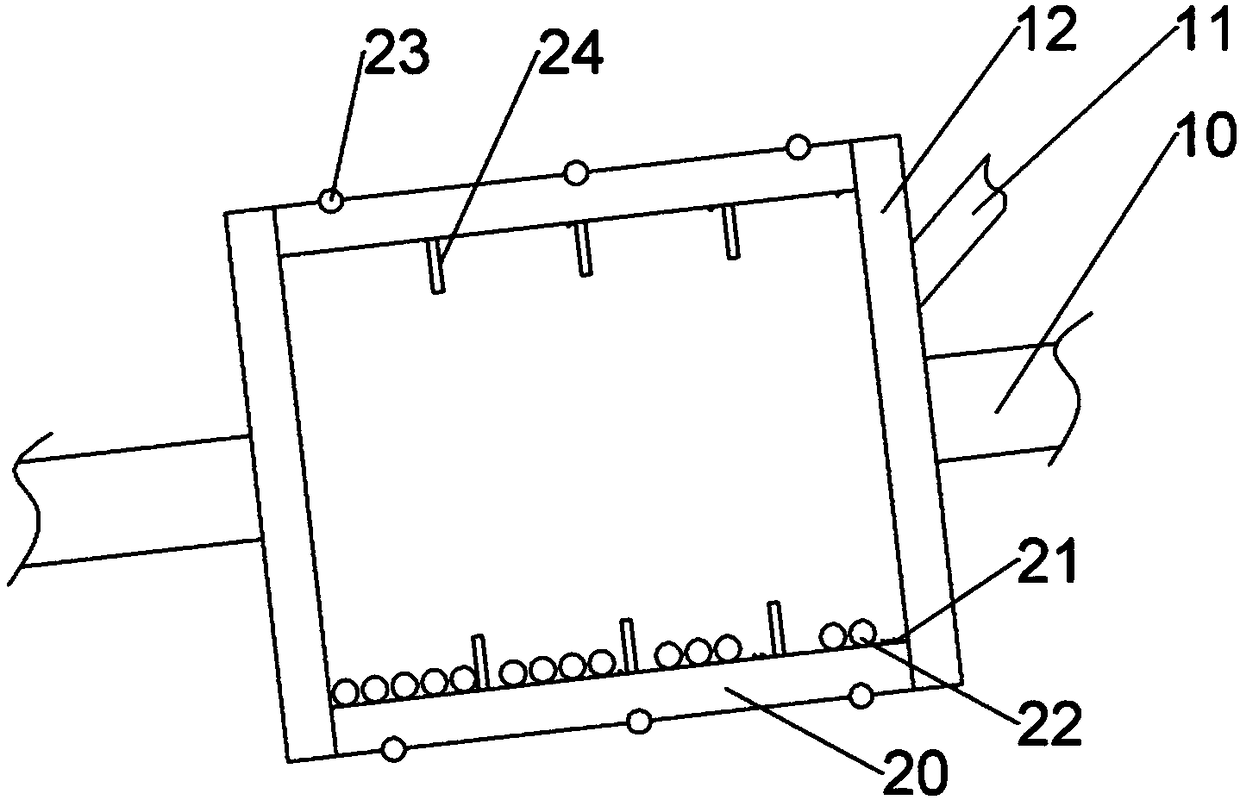

[0031] Basic as attached figure 1 Shown: A crushing device for construction, including a frame, on which a feeding pipe, a front shaft, a front support frame, an elastic cylinder wall, a crushing mechanism, a rear support frame, and a rear shaft are arranged inclinedly in sequence along the direction of material travel .

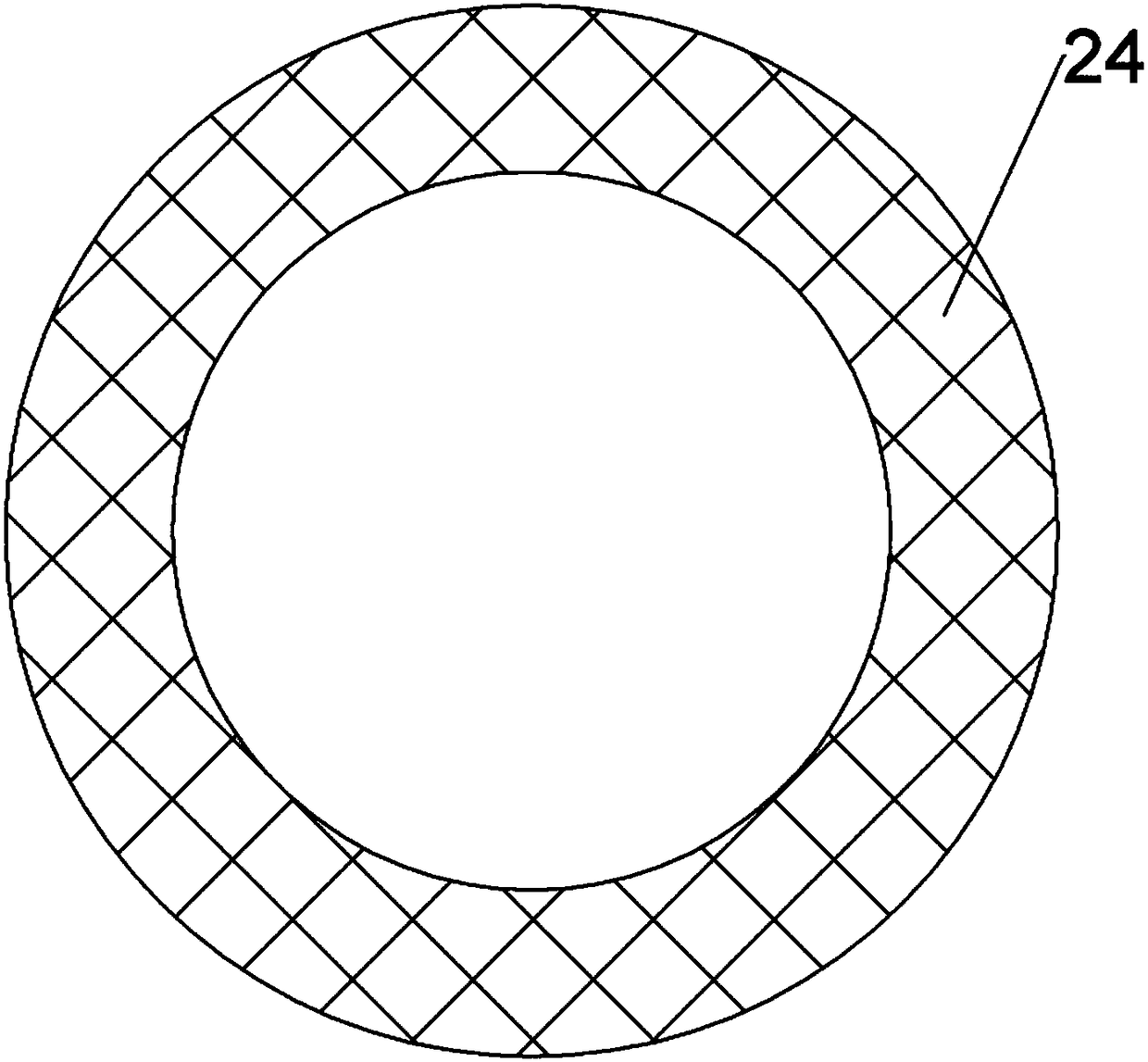

[0032] Among them, the elastic cylinder wall is surrounded by a number of independently arranged airbags along the circumferential direction. The airbags are evenly arranged and bonded and fixed between two adjacent airbags. The outer wall of the airbag is provided with an air intake check valve, and the inner wall of the airbag is provided with several air outlet check valves. One-way valve, the number of air outlet one-way valves gradually decreases from front to back, and the crushing mechanism includes an annular screen set on the inner wall of the air bag.

[0033] Such as figure 2 As shown, there are several sieve holes on the ring screen, and the r...

Embodiment 2

[0046] The only difference from Example 1 is: in step 1, the building materials are transported 1.3 tons every half hour; in step 2, the speeds of the front and rear shafts are both 34r / min; in step 4, the power is turned on every half hour for 6 minutes; The middle front shaft and the rear shaft continue to run for 2.5 minutes before closing.

Embodiment 3

[0048] The only difference from Example 1 is: in step 1, the building materials are transported 1.5 tons every half hour; in step 2, the speeds of the front and rear shafts are both 45r / min; in step 4, the power is turned on for 10 minutes every half hour; The middle front shaft and the rear shaft continue to run for 3 minutes before closing.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com