Solid material grinding device

A solid material and grinding device technology, applied in grain processing and other directions, can solve the problems of different grinding particle sizes, reduced efficiency, slowness, etc., to reduce the probability of secondary rework grinding, increase availability, and improve the effect of fineness

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

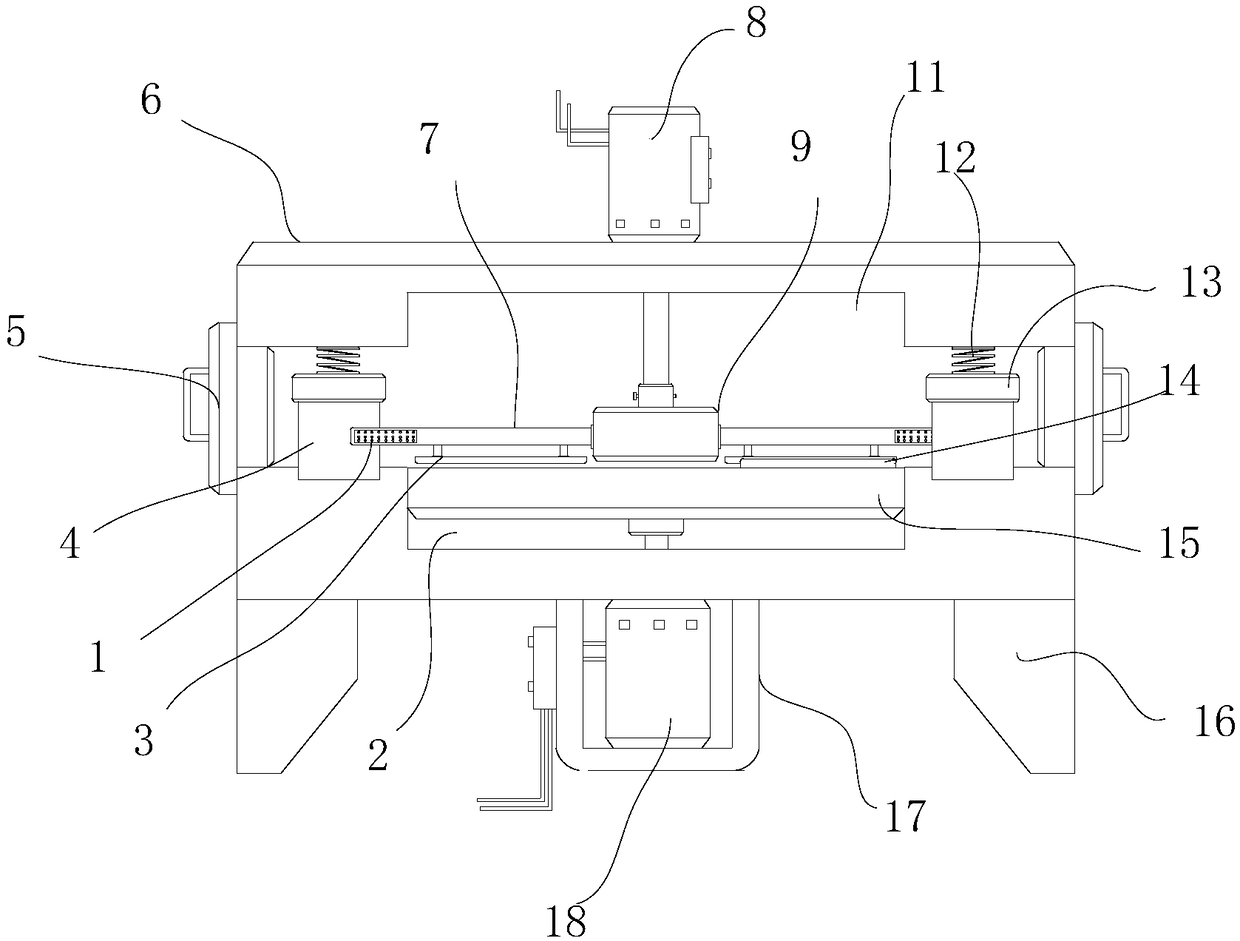

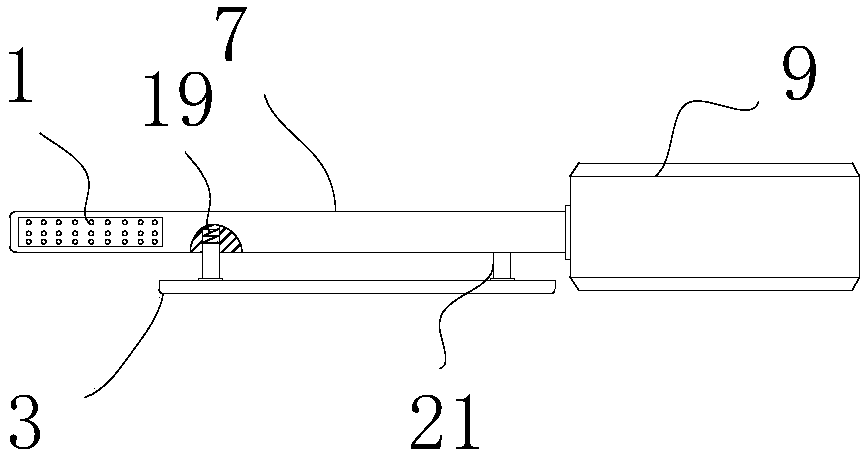

[0015] Such as figure 1 As shown, the grinding device for solid materials includes a device box 6, a first drive motor 8 is installed on the top of the device box 6, and the motor shaft of the first drive motor 8 passes through the device box and extends into the middle of the device box. In the grinding chamber 11, a rotating disc 9 is fixedly installed at the protruding end thereof, and the rotating disc 9 is driven to rotate by the first driving motor 8, and a grinding blade 7 is respectively arranged on both sides of the rotating disc 9;

[0016] The bottom surface of the grinding chamber 11 of the device box 6 is provided with an installation chamber 2, and a grinding block 15 is loaded in the installation chamber 2. The outer diameter of the grinding block 15 is slightly smaller than the inner diameter of the installation chamber, and the sealing must be guaranteed, and it cannot be in contact with the inner wall of the installation chamber. The two sides of the device b...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com