A multifunctional coating die head

A multi-functional, die-head technology, which is applied to the device and coating of the surface coating liquid, can solve the problems of poor coating quality, uniformity, and inconsistent thickness, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

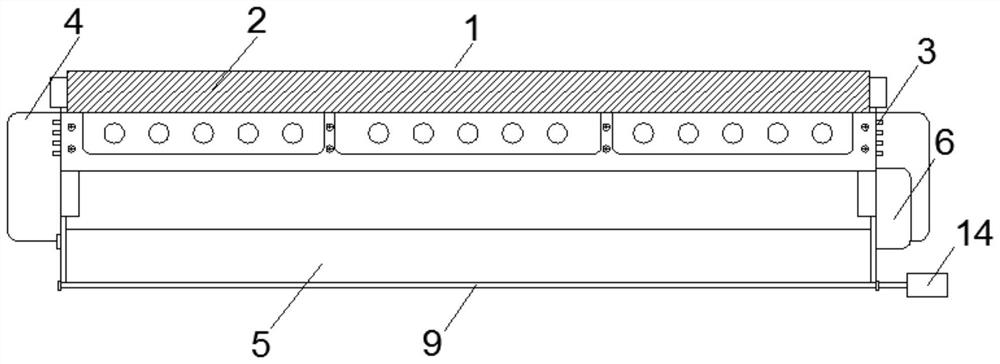

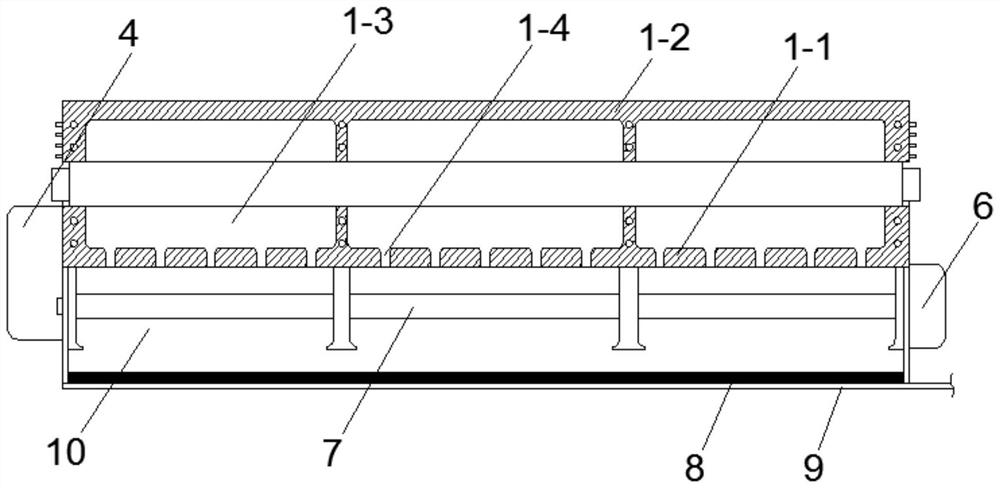

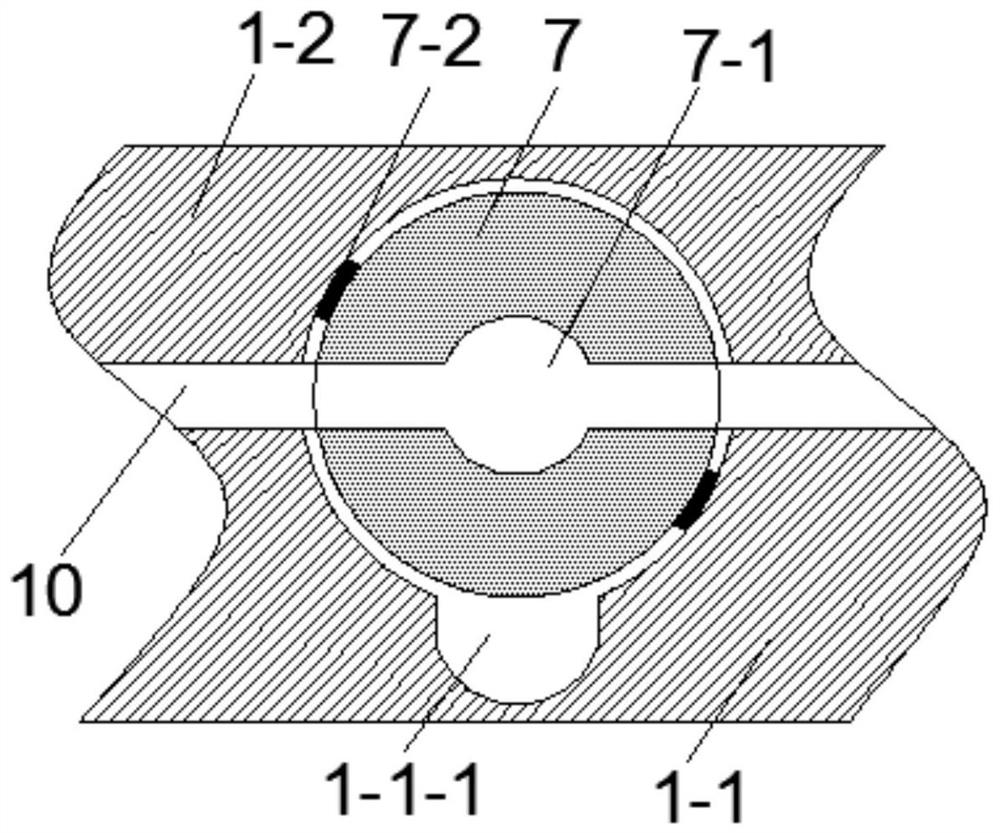

[0020] Such as figure 1 , figure 2 and Figure 4 Shown, a kind of multifunctional coating die head comprises die head frame and die head; Described die head frame 1 comprises upper cavity shell 1-2 and lower cavity shell 1-1, and described upper cavity shell 1-2 passes through The rotating shaft 2 is connected with the lower chamber shell 1-1, and the lower end of the lower chamber shell 1-1 is sealed and connected with the die head 5, and the die head 5 is connected with the coating roller 9 through the stopper 8, and the center of the coating roller 9 is inserted The key shaft 9-1 is connected with the adjustment mechanism 14. Wherein, the present invention is based on the die frame 1, and the die frame 1 is composed of an upper chamber shell 1-2 and a lower chamber shell 1-1 folded and connected. The traditional die frame 1 is fixed and welded, so it does not have the function of secondary repair, which greatly reduces the use efficiency. The upper chamber shell 1-2 an...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com