Acoustic impedance matching layer of ultrasonic transducer and manufacturing method thereof

A technology for ultrasonic transducers and manufacturing methods, which can be applied to sound-producing devices, instruments, and fluids using vibrations, etc., and can solve problems such as difficulty in implementation, large sensitivity limit of ultrasonic transducers, and low efficiency of acoustic energy transmission, and achieve operability strong effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

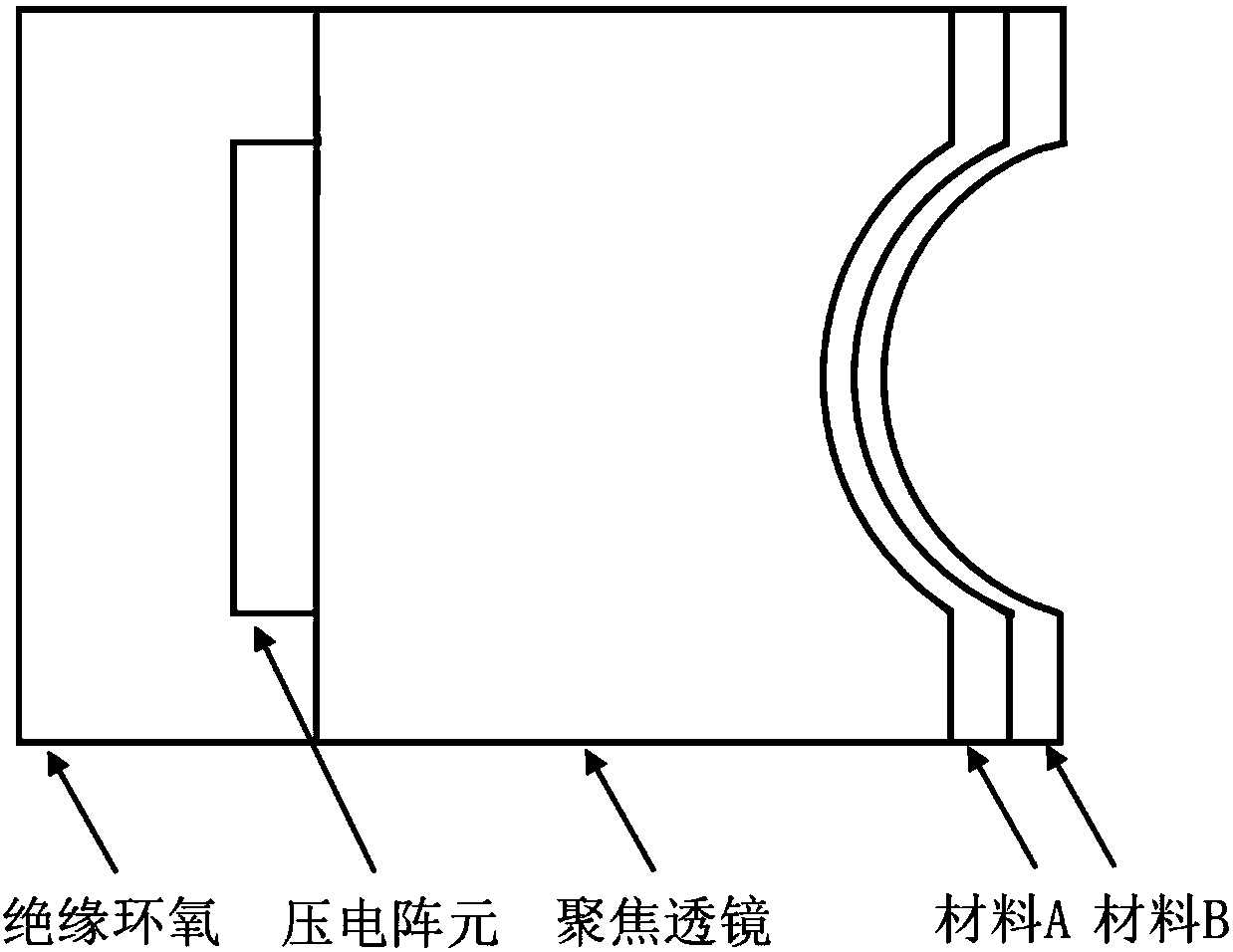

[0020] An acoustic impedance matching layer of an ultrasonic transducer, comprising a low-density sound velocity layer and a high-density sound velocity layer arranged in sequence, the low-density sound velocity layer is composed of material A, the high-density sound velocity layer is composed of material B, the low-density sound velocity layer and the focusing lens The surface is connected, and the high-density sound velocity layer is exposed to the air or connected to other devices.

[0021] The material A is a polymer resin material, and the polymer resin material is composed of any one of epoxy and parylene; the material B is a metal material, and the metal material is composed of any one of gold, silver, and copper.

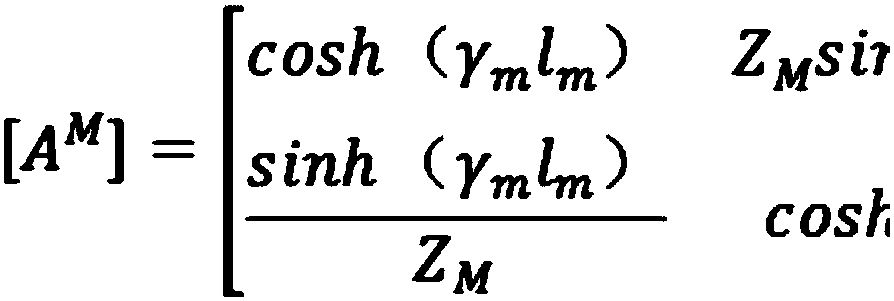

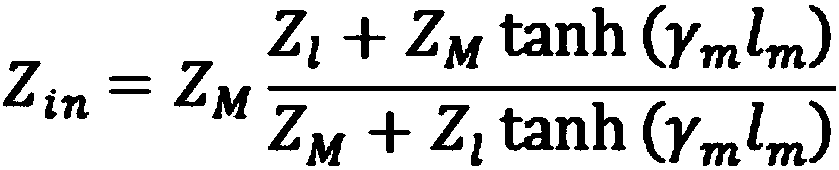

[0022] Since the length of the focusing lens is much longer than that of the piezoelectric array element, when using the transmission line theory for impedance matching, the matching impedance value is set as the characteristic impedance value of the focusing...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com