Automatic feeding, pressing and cutting machine

An automatic feeding and cutting machine technology, applied in metal sawing equipment, sawing machine equipment, metal processing equipment, etc., can solve the problems of worker injury, instability, poor manual cutting quality, etc., to achieve high safety performance, fast efficiency, Good cutting quality

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

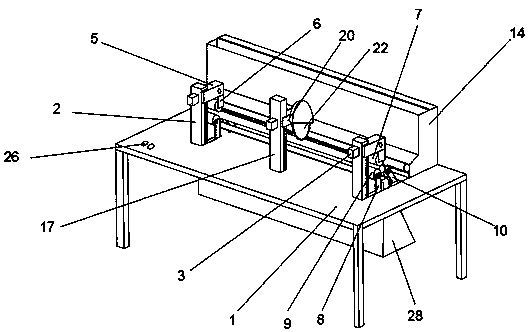

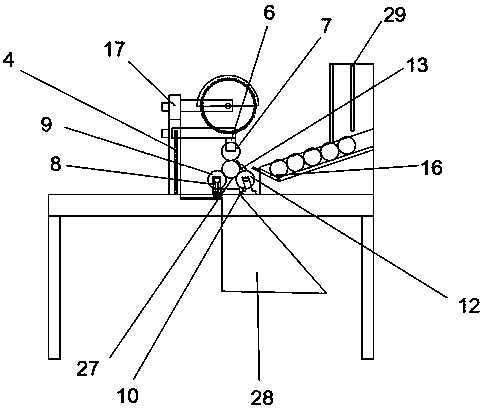

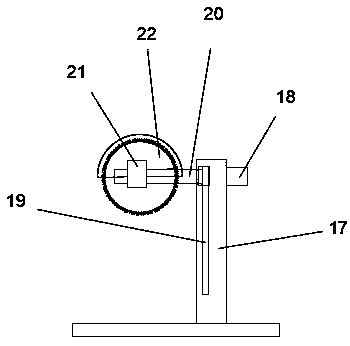

[0023] Embodiment: including a frame body 1, a pair of pressure roller columns 2 are arranged on both sides of the frame body 1, and a first slide rail 4 controlled by a first servo motor 3 is arranged on the pressure roller column 2, and a first slide rail 4 is provided on the first slide rail 4. The first lifting slider 5, a pair of pressure wheel plates 6 are arranged below the first lifting slider 5, and the lifting pressure wheels 7 are arranged on the pressure wheel plate 6; 2 side sliding plates 8, sliding plate 8 is provided with sliding pressure roller 9; Described frame body 1 both sides is provided with a pair of rotating wheel pressing plate 10, and rotating wheel pressing plate 10 side is provided with rotating servo motor 11, and rotating servo motor The output end of 11 is connected with rotating pinch wheel 12, and the surface of rotating pinch wheel 12 is provided with first baffle 13; There is a pair of second baffles 16 controlled by the torsion spring 15, a...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com