Flat cutting device used before deep processing of giant yellow bamboos

A technology for deep processing and giant yellow bamboo, applied in the field of bamboo processing equipment, can solve the problems of inability to cut bamboo with different diameters, limited functions, hidden dangers, etc., and achieves the effect of reducing hidden dangers, not easy to spread, and ensuring stability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

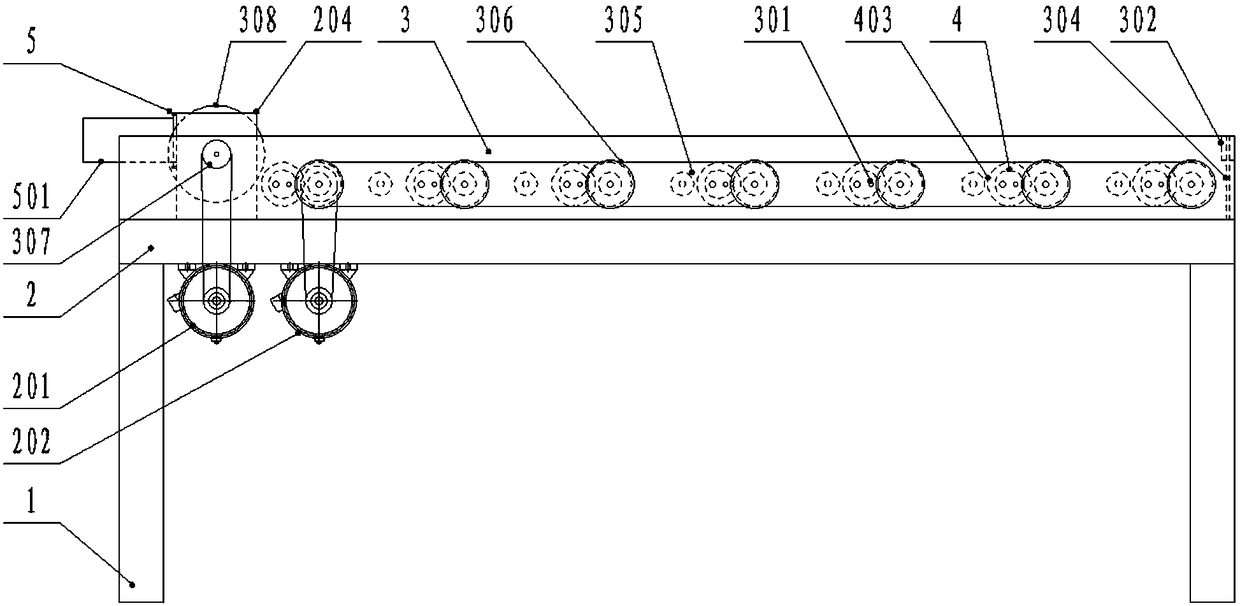

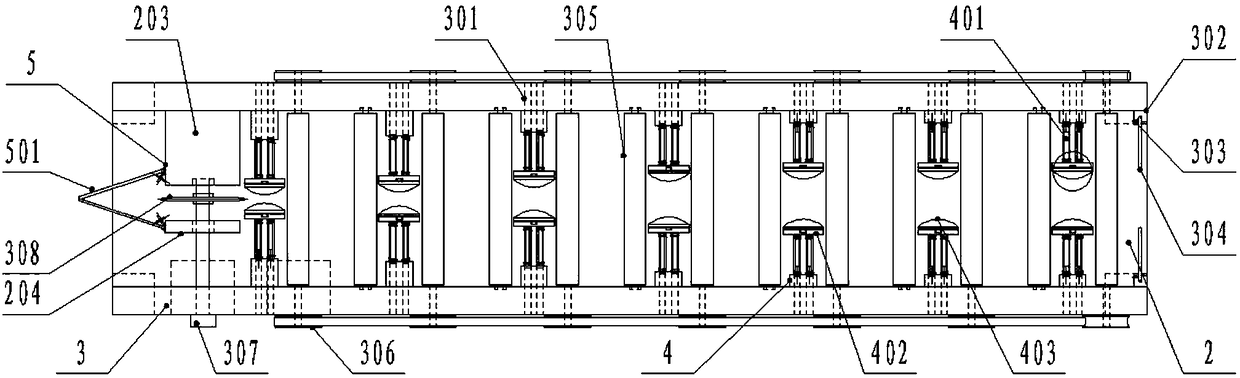

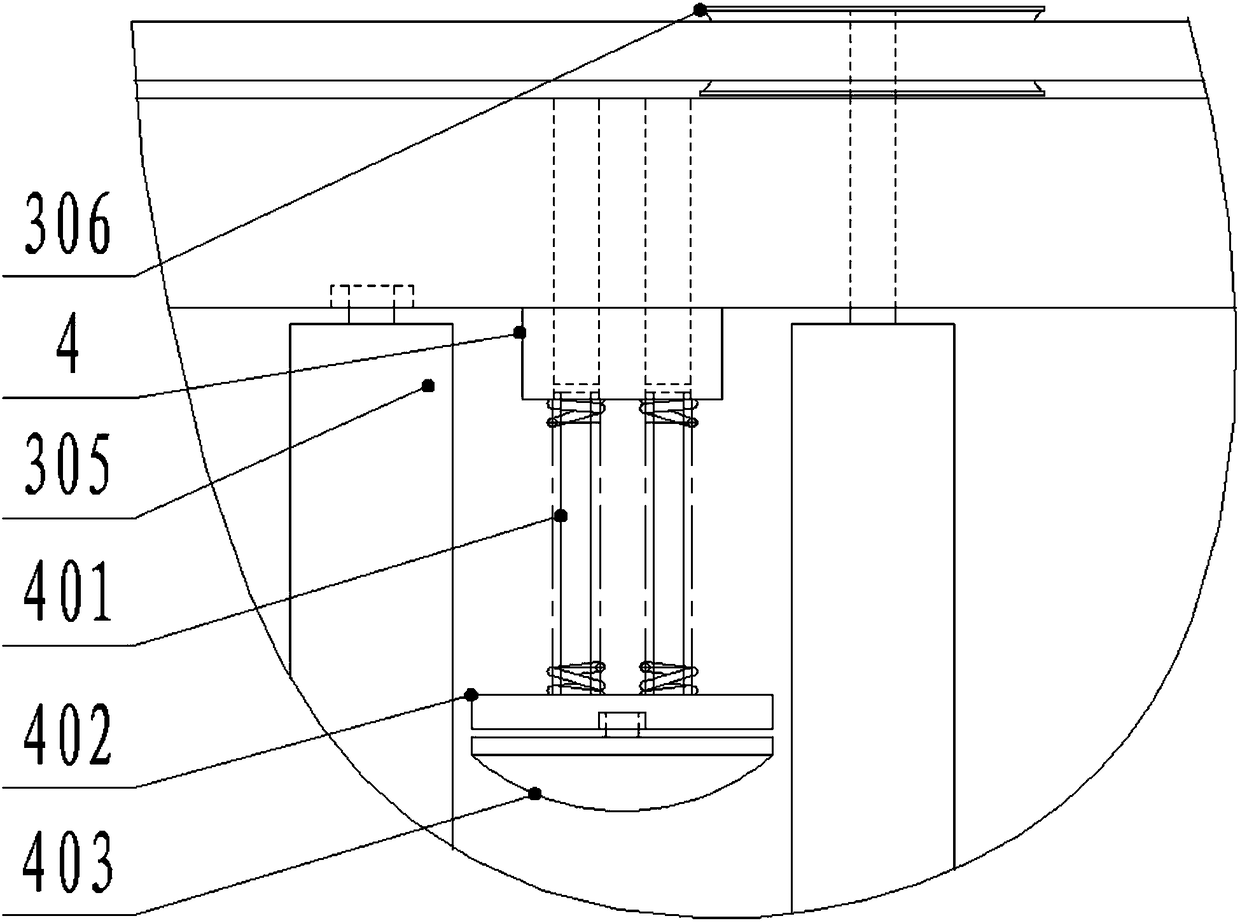

[0038] as attached figure 1 To attach Figure 11 Shown: a flat cutting device used before the deep processing of giant yellow bamboo, including a column 1, a top plate 2, a first reduction motor 201, a second reduction motor 202, a rear tool rest 203, a front tool rest 204, a side plate 3, Telescopic hole 301, swing block 302, top 303, swing plate 304, guide roller 305, pulley 306, pulley 307, rotary blade 308, base block 4, telescopic shaft 401, pressing block 402, arc block 403, fixed block 5 and The converging plate 501; the column 1 is a square tube structure with four places in total, which are welded to the four corners of the bottom side of the top plate 2; the top plate 2 is a rectangular plate; the first gear motor 201 and the second gear motor 202 are fixed on the bottom side of the top plate 2 by bolts , and the first reduction motor 201 is located on the left side of the second reduction motor 202; there are two side plates 3, which are rectangular plates, which are...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com