Special thermal transfer printer for taper product

A thermal transfer machine and product technology, applied in the direction of rotary printing machine, printing machine, transfer printing, etc., can solve the problems of easy damage of parts, substrate film crimping and shifting, large rotational inertia of the bottom plate, etc., and achieve product quality The effect of stability and efficiency improvement

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0023] The following are specific embodiments of the present invention and in conjunction with the accompanying drawings, the technical solutions of the present invention are further described, but the present invention is not limited to these embodiments.

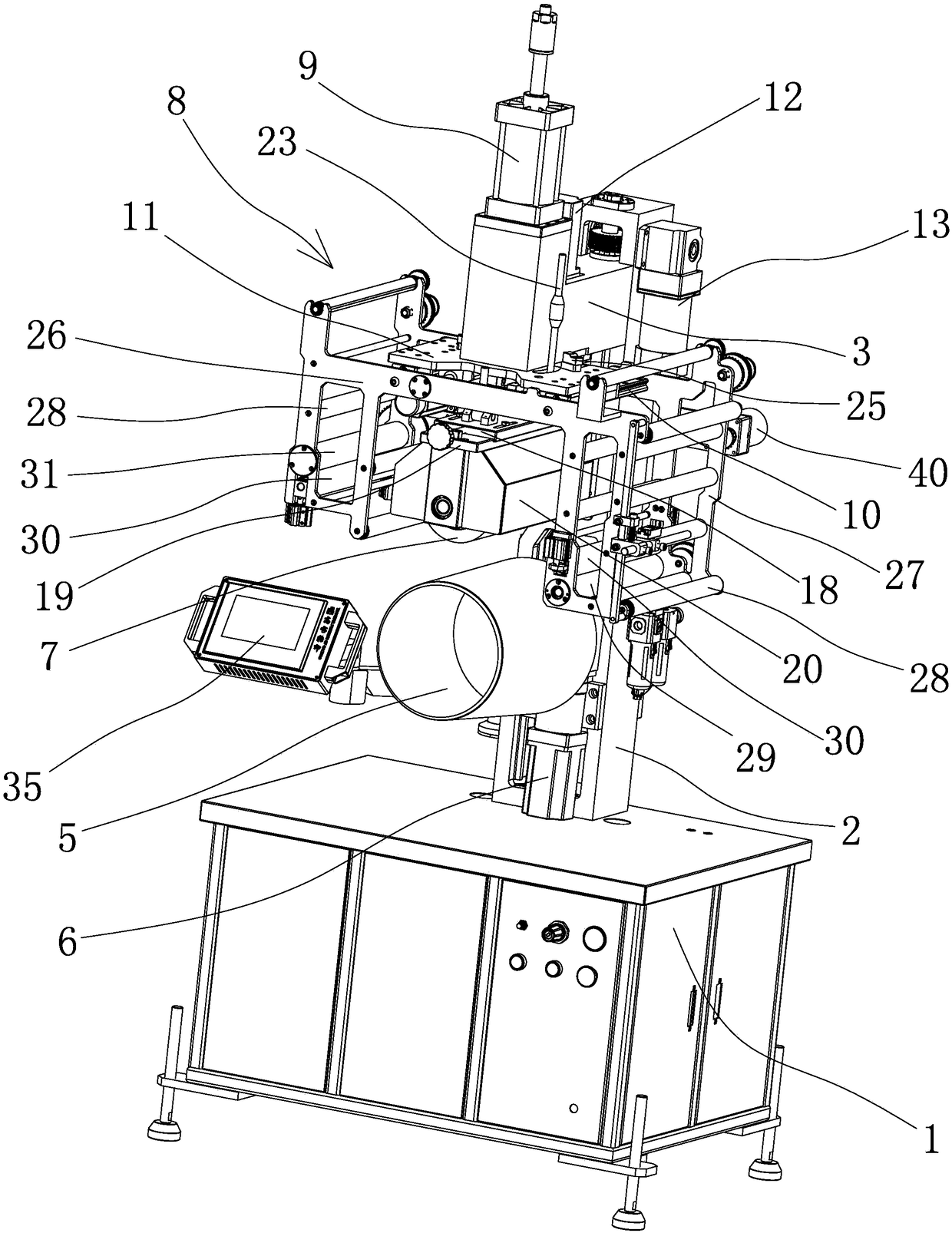

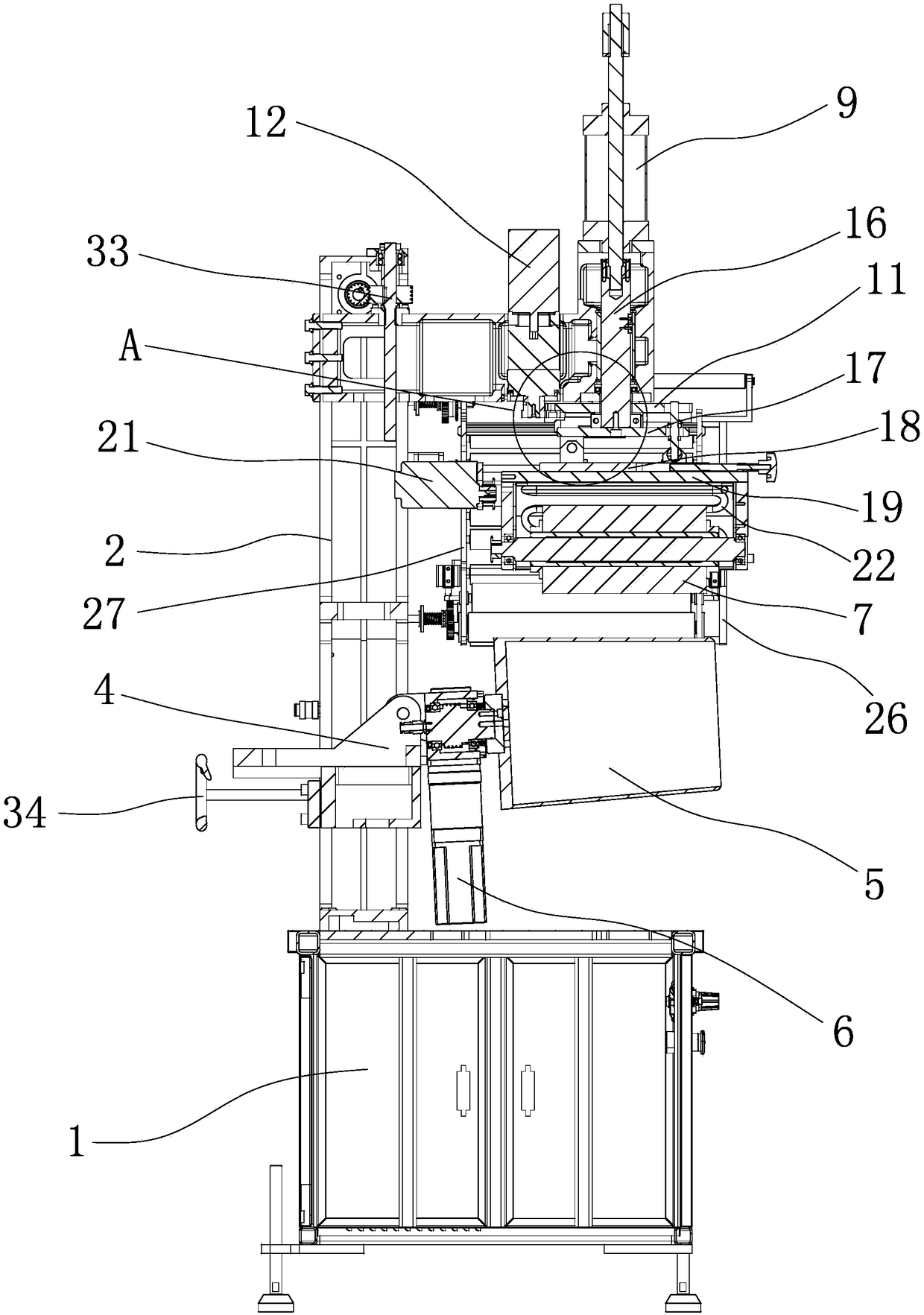

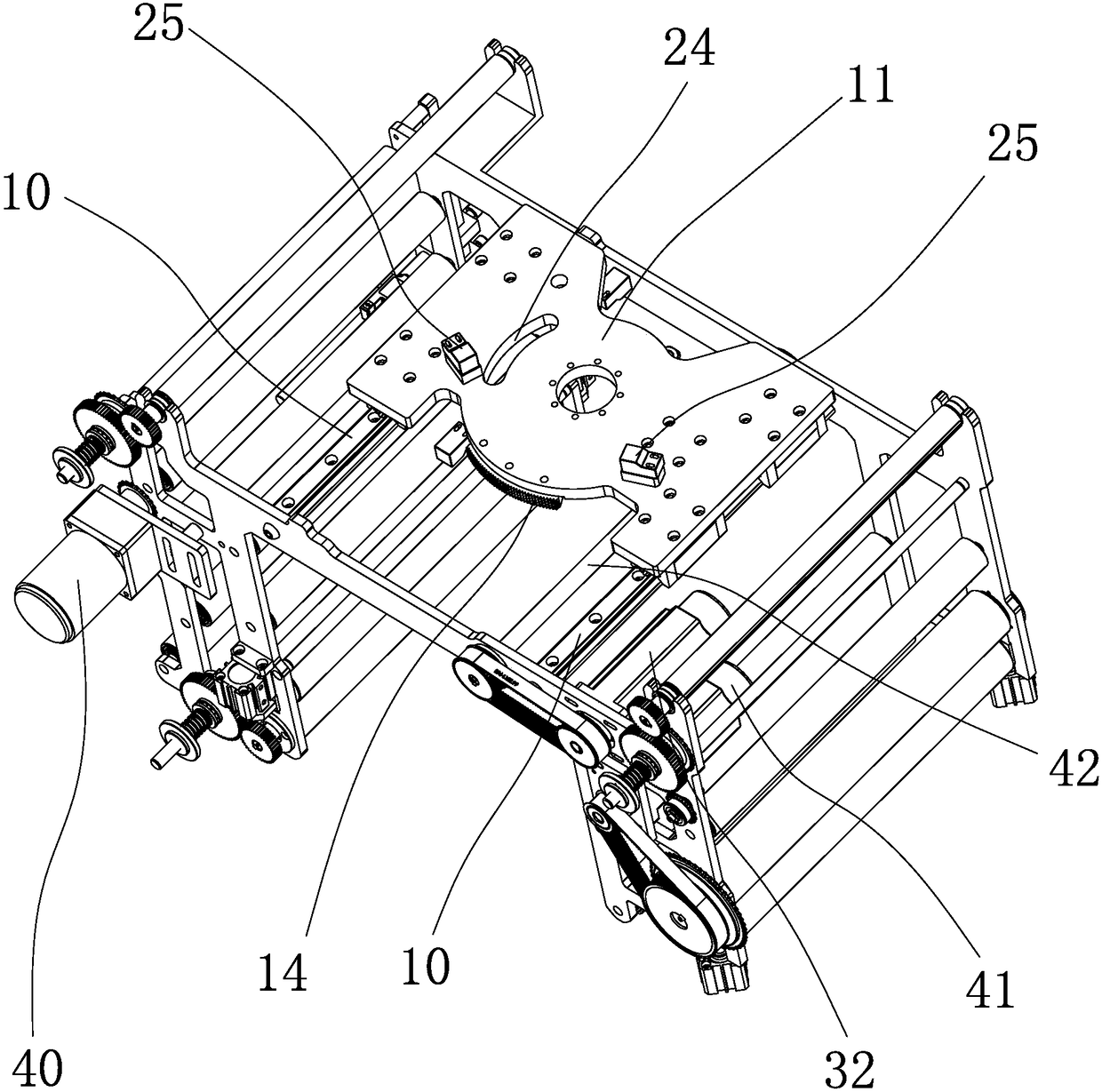

[0024] Such as figure 1 , figure 2 , image 3 , Figure 4 , Figure 5 As shown, the special thermal transfer machine for taper products includes a control panel 35, a base 1 and a column 2 arranged on the base 1. The upper part of the column 2 is provided with a cantilever 3 that can be lifted and lowered, and the lower part is provided with a multi-directional tooling that can adjust the angle. 4. The multi-directional tooling 4 is equipped with a substrate transfer roller 5 and a motor 6 that controls the turnover of the substrate transfer roller 5, and a liftable hot stamping rubber roller is installed at the position between the cantilever 3 and the substrate transfer roller 5 7 and a rotatable film frame 8, the t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com