Construction method of walking trackless triangular hanging basket

A technology of a triangular hanging basket and a construction method, which is applied in construction, bridge construction, bridges, etc., can solve the problems of high construction cost, easy overloading of shear stress, and high structural strength requirements of main truss longitudinal beams.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment approach 1

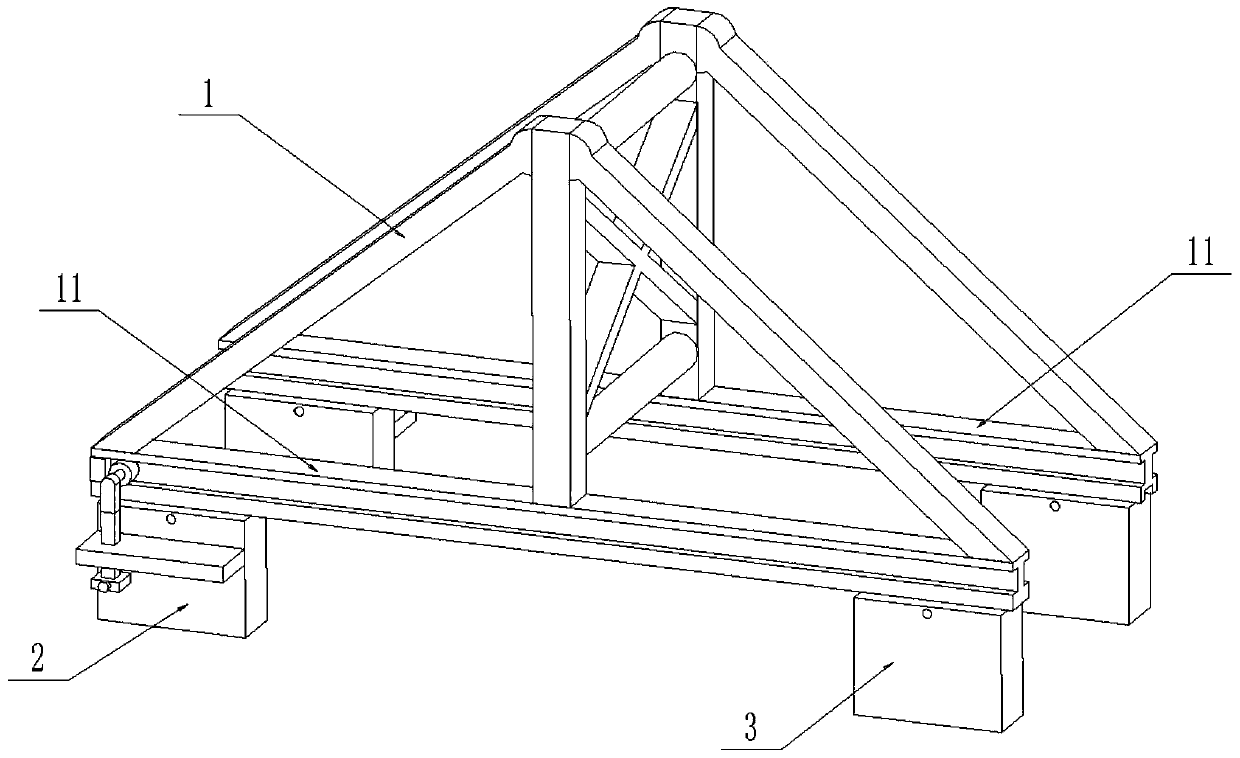

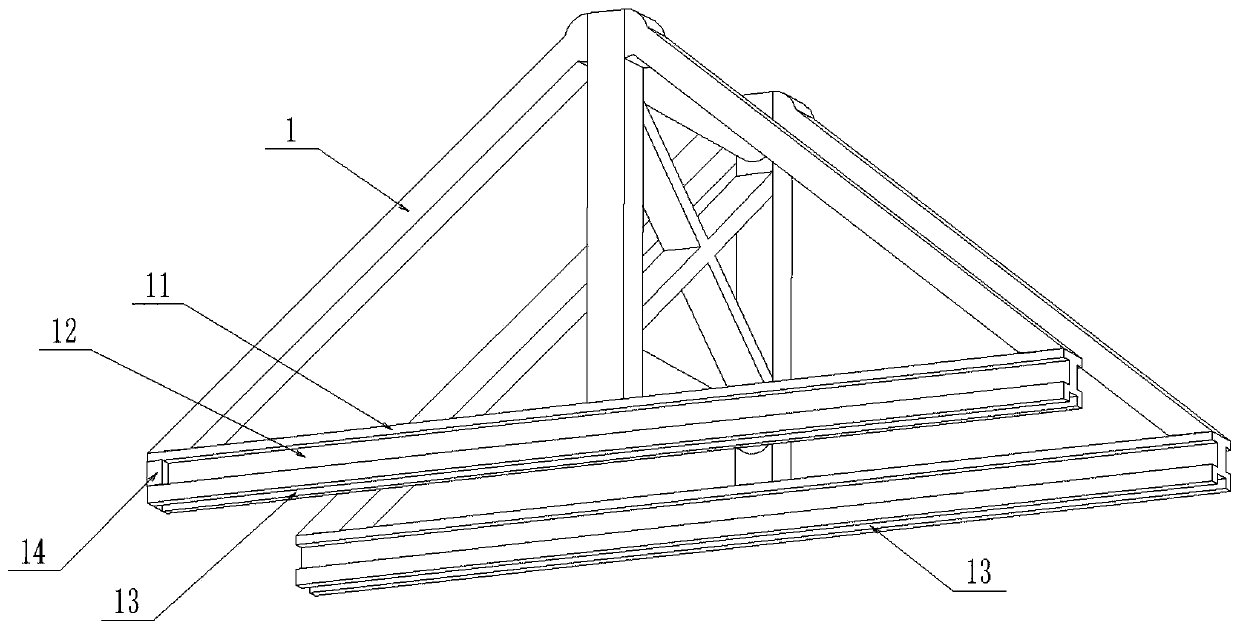

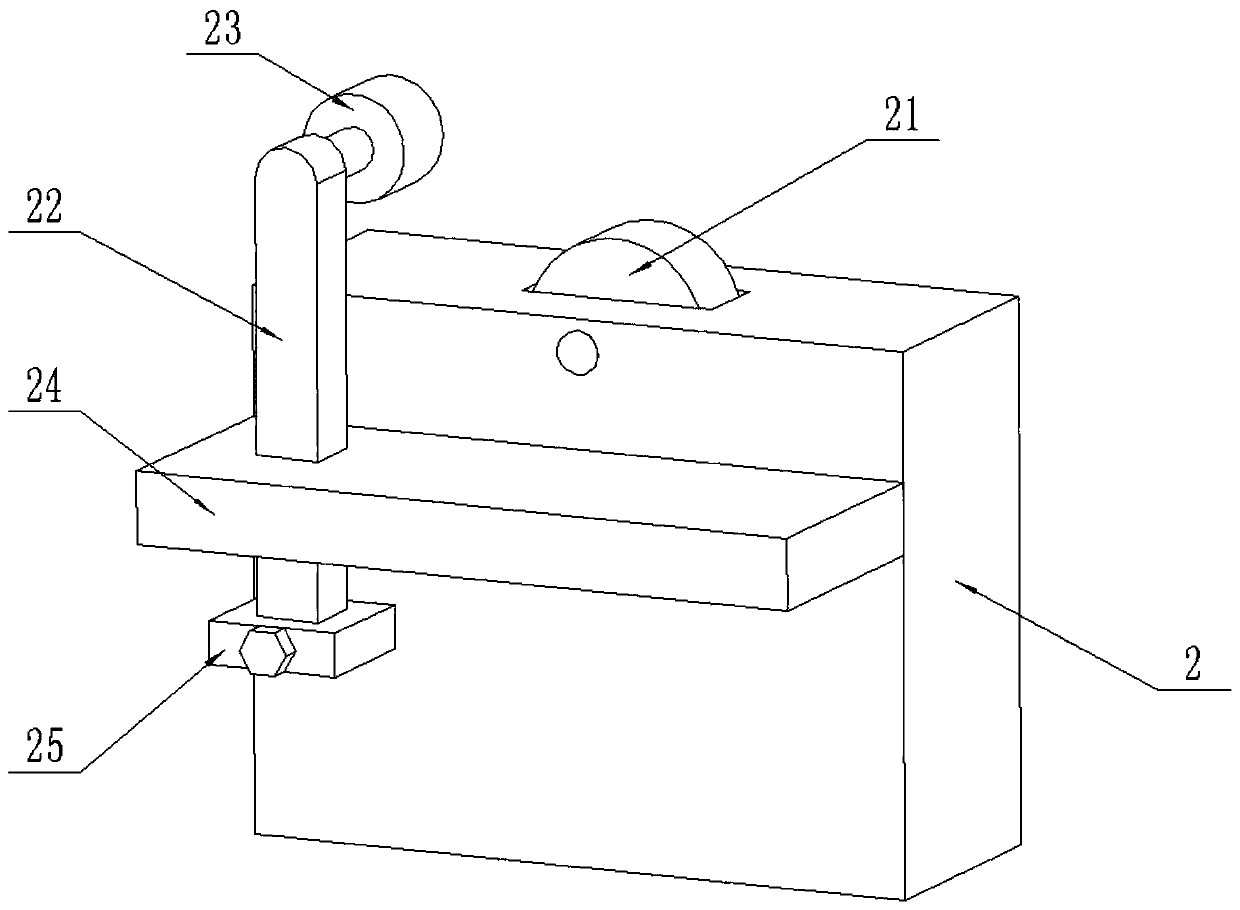

[0031] Combine below Figure 1-4 Illustrate the present embodiment, the walking type trackless triangular hanging basket construction method, comprises the following steps: (1) the front walking support seat 2 and the rear walking support seat 3 are set at the front and rear ends of the main truss longitudinal beam 11 of the triangular hanging basket, and the front walking support seat 3 The top of the supporting seat 2 is provided with a walking pressing wheel I21 and a walking pressing wheel II23, the walking pressing wheel II23 is located at the upper end of the walking pressing wheel I21, and the top of the rear walking supporting seat 3 is provided with a walking pressing wheel III31, The front end of the main truss girder 11 of the triangular hanging basket is clamped between the traveling pressing wheel I21 and the traveling pressing wheel II23, and the rear end of the main truss longitudinal beam 11 of the triangular hanging basket is pressed on the traveling pressing w...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com