Core-wall rock-fill dam

A technology of rockfill dam and core wall, applied in dams, barrages, barrages, etc., can solve problems such as adverse environmental impact and increase in economic costs, achieve significant economic effects, reduce waste materials, and solve engineering earth-rock balance problems Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

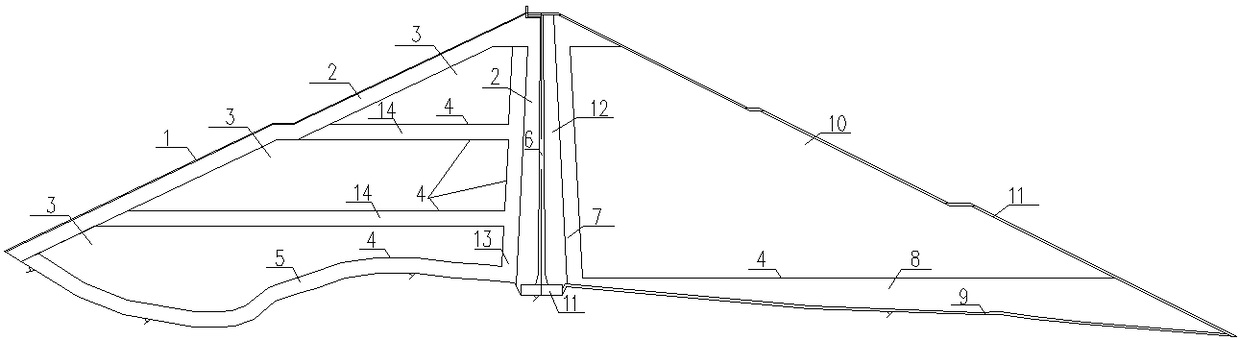

[0026] Such as figure 1 As shown, a core wall rockfill dam includes a core wall 6, and a first rockfill layer 5 is provided at the bottom of the core wall 6 on the upstream side. A first soft rock filling area 3 is arranged from bottom to top from the first rock-fill layer 5 . The non-bottom area of the first soft rock filling area 3 is covered with a first transition material layer 2 that completely wraps the outer surface of the first soft rock filling area 3 .

[0027] In the first soft rock filling area 3, there is a rockfill separation structure that can divide the first soft rock filling area 3 into blocks for stable support. The rock-fill separation structure includes a second rock-fill layer 13 that is set from bottom to top close to the downstream side of the first soft rock filling area 3 and is at the same height as the first soft rock filling area 3. At least one layer horizontally arranged in the filling area 3 divides the first soft rock filling area 3 into a...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com