Novel spray type glazing machine

A technology of spraying and ice-packing machines, which is applied in the direction of ice making, ice making, cooling machines, etc. It can solve the problems of inability to connect with other equipment, large turning radius of the mesh belt, time-consuming and laborious installation, etc., and achieves a small footprint , Reduce the radius of gyration and reduce the cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

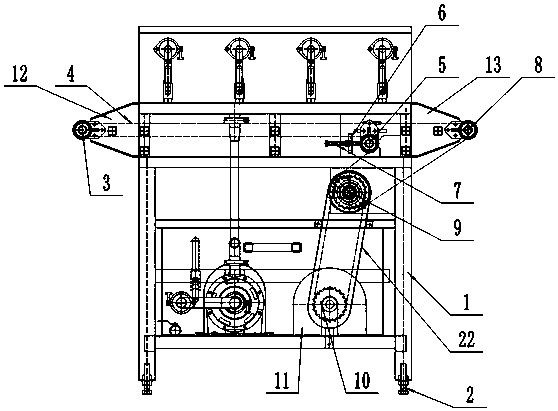

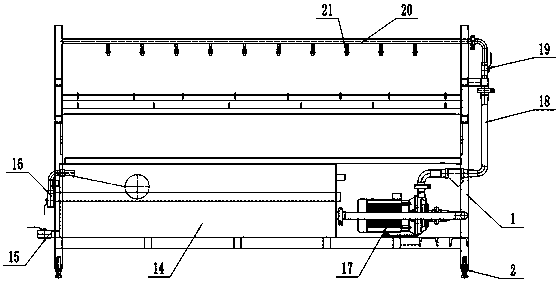

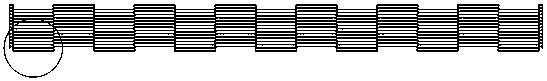

[0018] Such as Figure 1 to Figure 6 As shown, this specific embodiment adopts the following technical solutions: a new type of spray ice packer, including a frame 1, a horizontal adjustment foot 2, a first reversing wheel 3, a B-shaped mesh belt 4, a tensioning wheel 5, Mounting block 6, bolt 7, second reversing wheel 8, transmission gear 9, rotating gear 10, rotating motor 11, first mounting plate 12, second mounting plate 13, water tank 14, drain valve 15, water inlet valve 16, Water pump 17, water pipe 18, valve 19, sprinkler pipe 20, nozzle 21 and chain 22; The lower end of described frame 1 is provided with several horizontal adjustment pads 2; The upper end left side of described frame 1 is fixedly connected with a first Mounting plate 12; the upper right side of the frame 1 is fixedly connected with a second mounting plate 13; the first mounting plate 12 is movably connected with a first reversing wheel 3; on the second mounting plate 13 A second reversing wheel 8 is ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com