Venturi pipe flow measuring device and mounting method

A Venturi tube, flow measurement technology, applied in the volume/mass flow generated by mechanical effects, and the detection of fluid flow by measuring pressure difference, can solve the problems of high manufacturing cost, fluid leakage, complex process, etc., to reduce production costs , The effect of reducing pressure loss and reducing processing difficulty

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

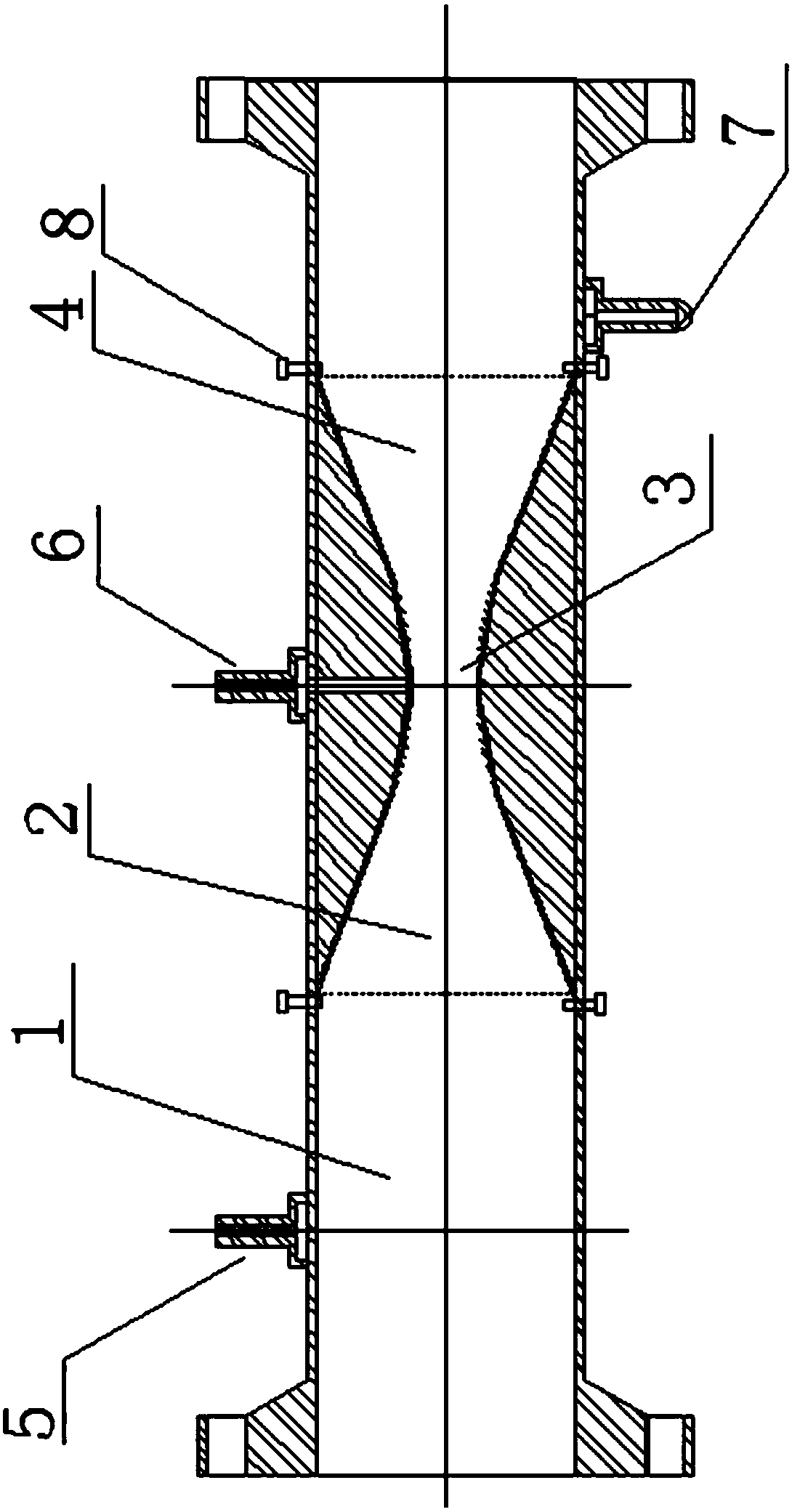

[0020] A Venturi tube flow measurement device, the flow measurement device includes an inlet cylinder section 1, a conical constriction section 2, a cylinder throat section 3 and a conical divergence section 4 arranged in sequence, on the inlet cylinder section 1 along There are positive pressure-taking holes 5 in the radial direction, and negative pressure-taking ports 6 are arranged in the radial direction in the cylindrical throat section 3, and the conical constriction section 2 of the Venturi tube, the cylindrical throat section 3 and the conical diffuser section 4 are integrated Molded casting, the outer diameter of the two ports of the conical constriction section 2 of the Venturi tube and the conical diffusion section 4 are adapted to the inner diameter of the inlet circular pipe section 1; the conical constriction section 2 of the Venturi tube, the cylindrical throat section 3 and the The section of the conical diffuser section 4 is a hyperbola, and the two ends of the...

Embodiment 2

[0023] A Venturi tube flow measurement device, the flow measurement device includes an inlet cylinder section 1, a conical constriction section 2, a cylinder throat section 3 and a conical divergence section 4 arranged in sequence, on the inlet cylinder section 1 along There are positive pressure-taking holes 5 in the radial direction, and negative pressure-taking ports 6 are arranged in the radial direction in the cylindrical throat section 3, and the conical constriction section 2 of the Venturi tube, the cylindrical throat section 3 and the conical diffuser section 4 are integrated Molded injection molded parts, the outer diameter of the two ports of the conical constriction section 2 and the conical diffusion section 4 of the Venturi tube are adapted to the inner diameter of the inlet circular pipe section 1; the conical constriction section 2 of the Venturi tube and the cylindrical throat section 3 The cross-section of the conical diverging section 4 is a hyperbola, and th...

Embodiment 3

[0026] A Venturi tube flow measurement device, the flow measurement device includes an inlet cylinder section 1, a conical constriction section 2, a cylinder throat section 3 and a conical divergence section 4 arranged in sequence, on the inlet cylinder section 1 along There are positive pressure-taking holes 5 in the radial direction, and negative pressure-taking ports 6 are arranged in the radial direction in the cylindrical throat section 3, and the conical constriction section 2 of the Venturi tube, the cylindrical throat section 3 and the conical diffuser section 4 are integrated Molded injection molded parts, the outer diameter of the two ports of the conical constriction section 2 and the conical diffusion section 4 of the Venturi tube are adapted to the inner diameter of the inlet circular pipe section 1; the conical constriction section 2 of the Venturi tube and the cylindrical throat section 3 The cross-section of the conical diffuser section 4 is a hyperbola, and the...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com