Threaded propulsion-type sample extractor

A technology of thread propulsion and extractor, which is applied in the preparation, sampling, and instrumentation of test samples, which can solve the problems of manual pressurized sampling and secondary pollution of extracted samples, and achieve the effect of avoiding secondary pollution

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

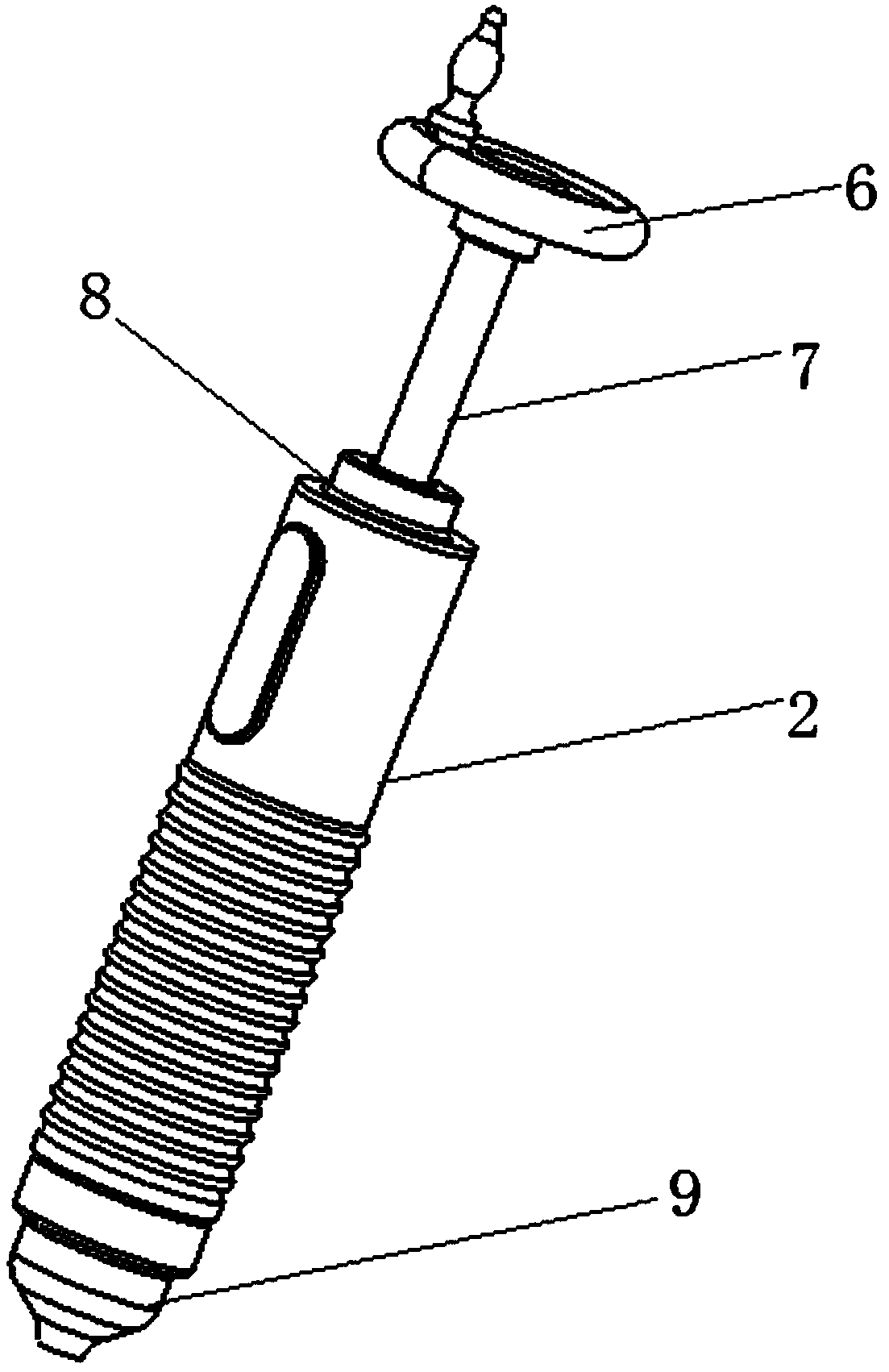

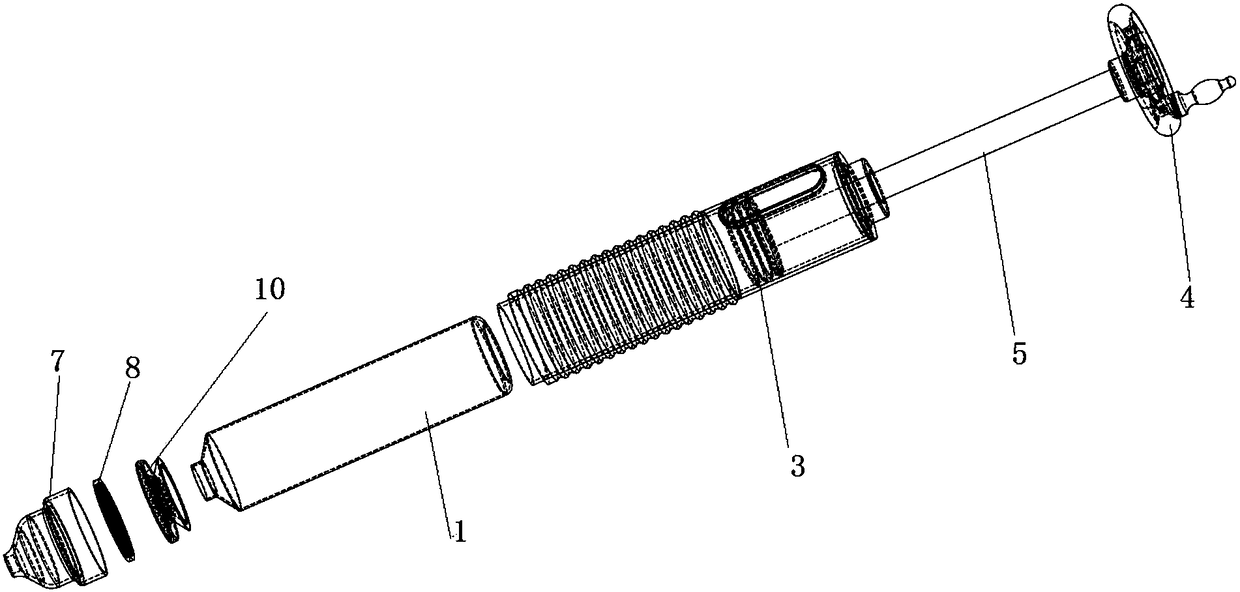

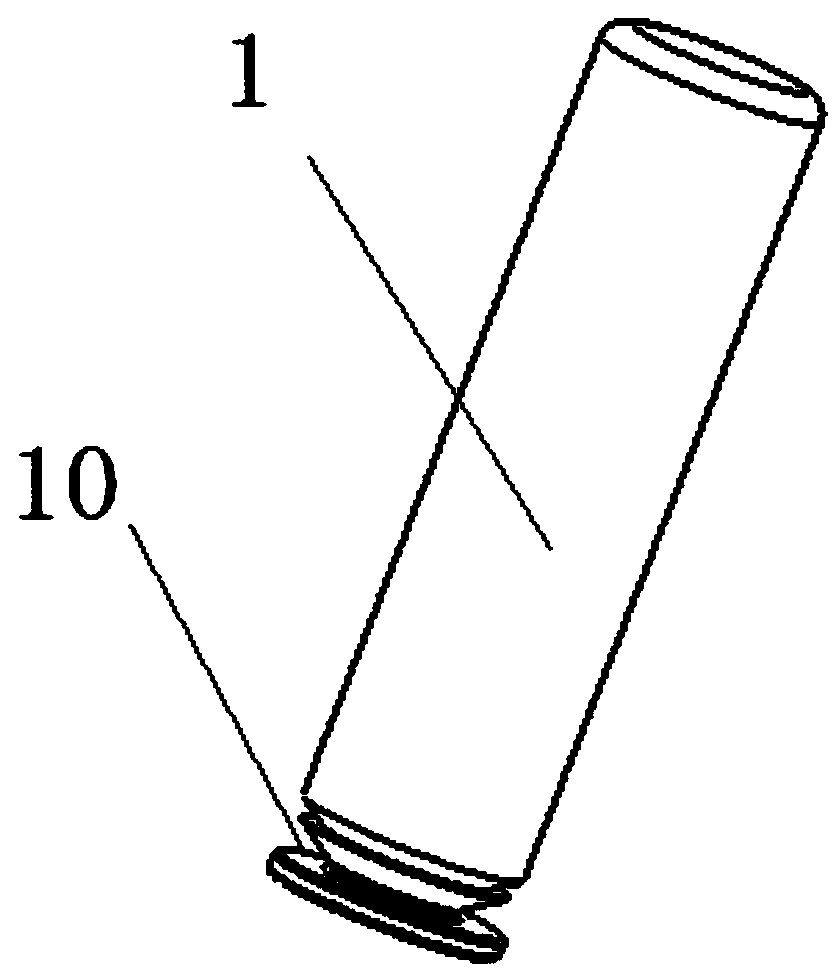

[0024] combine Figure 1 to Figure 4 , the present invention provides a screw pusher type sample extractor, comprising a retractable sample volumetric flask 1, a sample extractor housing 2, a pressure detection module 3, a screw type propulsion device and a filter device.

[0025] During operation, firstly, the original solution is poured into the retractable sample volumetric flask 1, and the retractable sample volumetric flask 1 is put into the sample extractor housing 2. Then the filter device is docked with the screw type propulsion device, and pressure is applied to the retractable sample volumetric flask 1 through the screw type propulsion device. Thereby forcing the retractable sample volumetric flask 1 to be compressed, the original solution therein passes through the filter membrane 9 placed in the filter device, the sample with a diameter greater than the filter membrane aperture will be filtered on the filter membrane, and the impurities and solution with a diameter...

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap