High speed rail cement sleeper detection system based on industrial vision

A technology for high-speed rail cement and detection system, which is applied in measurement devices, optical testing of flaws/defects, image data processing, etc. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

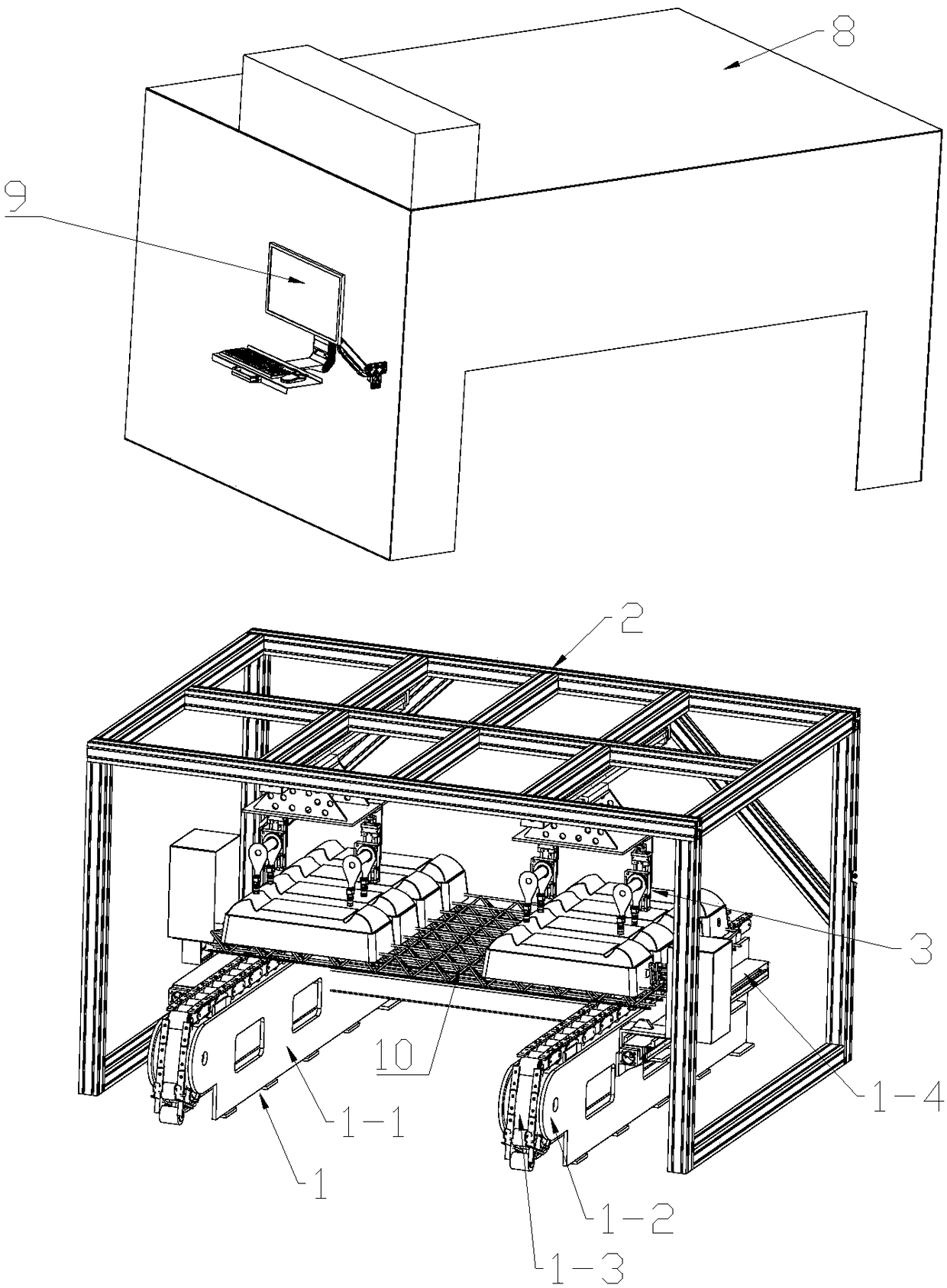

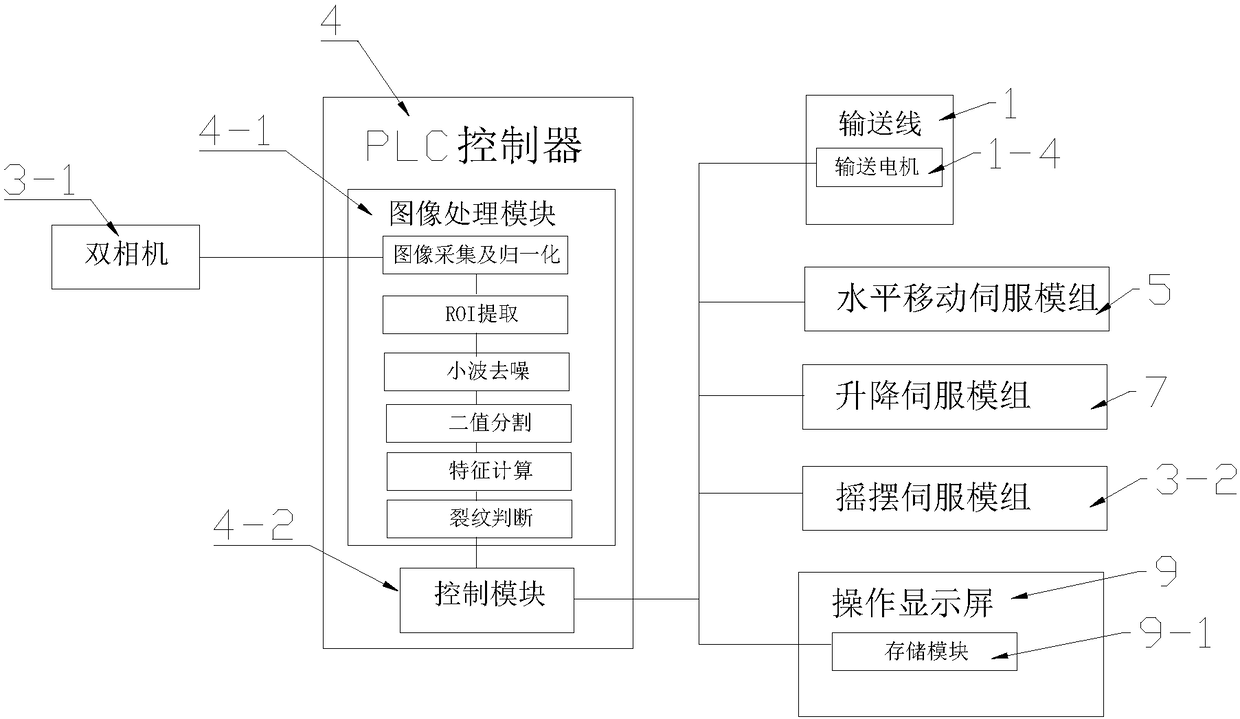

[0021] Such as Figure 1-3 As shown, a high-speed rail cement sleeper detection system based on industrial vision includes a conveying line 1 for conveying cement sleepers, a cover frame 2 covering the conveying line 1 , a The industrial camera group 3, the industrial camera group 3 is used to collect the surface image signal of the cement sleeper, and also includes a PLC controller 4, wherein:

[0022] The conveying line 1 comprises a conveying frame 1-1, a symmetrically arranged conveying wheel 1-2, a conveying belt 1-3 and a conveying motor 1-4, and the conveying belt 1-3 is wound around a pair of conveying wheels 1-2 , the conveying line 1 is powered by a conveying motor 1-4 to complete the transportation, and the paired conveying wheels 1-2 are arranged on both sides of the conveying frame 1-1, and the conveying motor 1-4 and the PLC controller 4 connection, the cement sleeper is set on the conveyor belt 1-3;

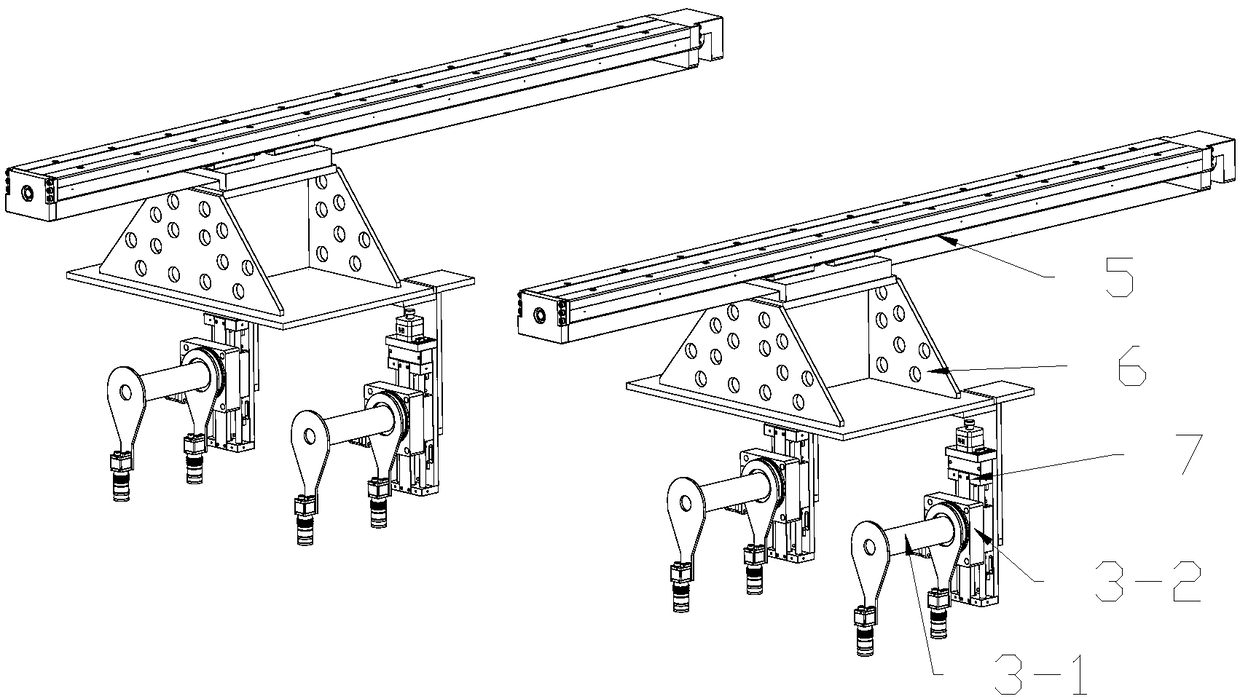

[0023] The industrial camera group 3 includes symmetrically...

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap