Staged wheel type robot moving path planning method

A wheeled robot and moving path technology, applied in the direction of instruments, non-electric variable control, two-dimensional position/channel control, etc., can solve the problems of deviation of the traveling path, loss of control of the wheeled robot, failure to reach the preset target state, etc. Achieve the effects of increasing fault tolerance, strong universality, and good stability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0034] The technical solutions of the present invention will be described in detail below in conjunction with the accompanying drawings and embodiments.

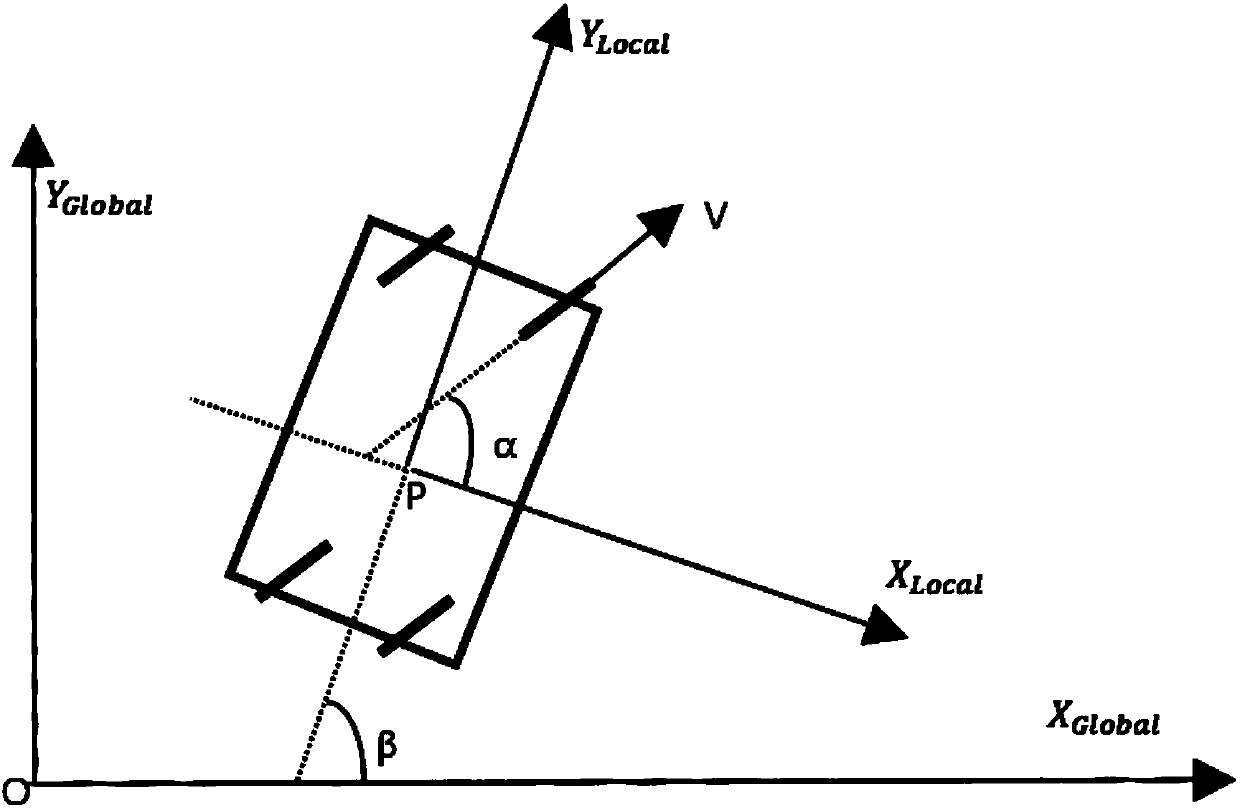

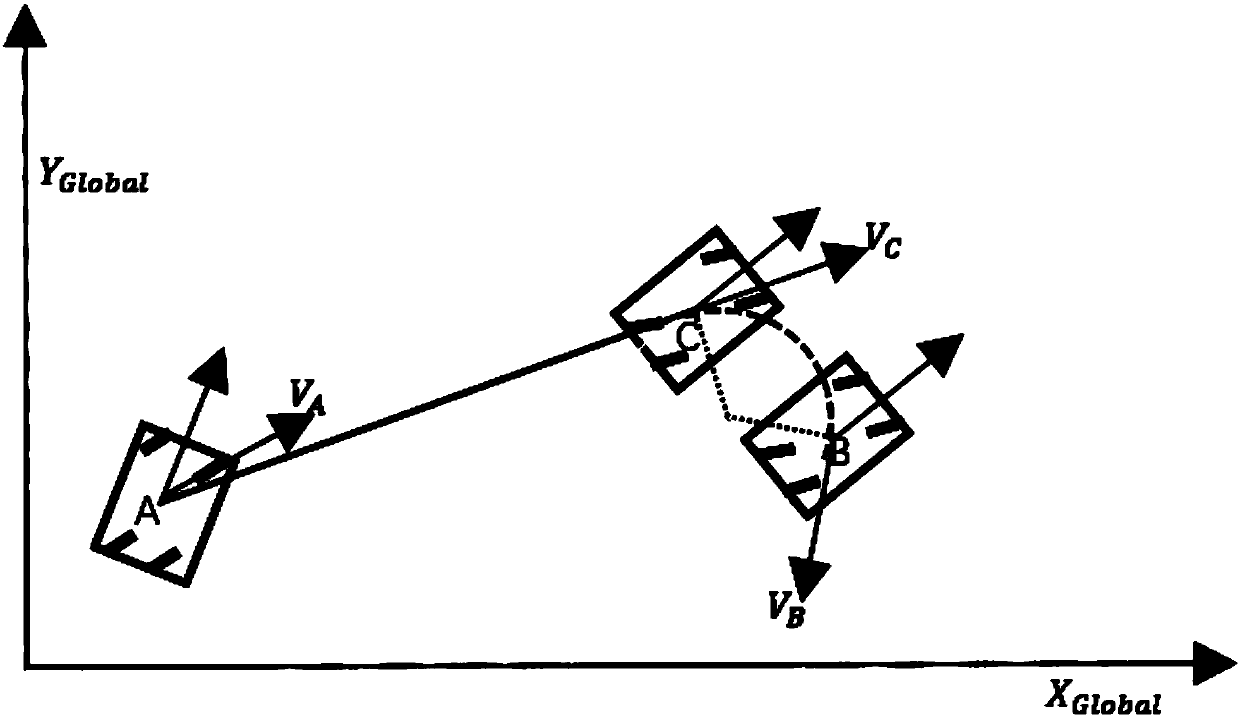

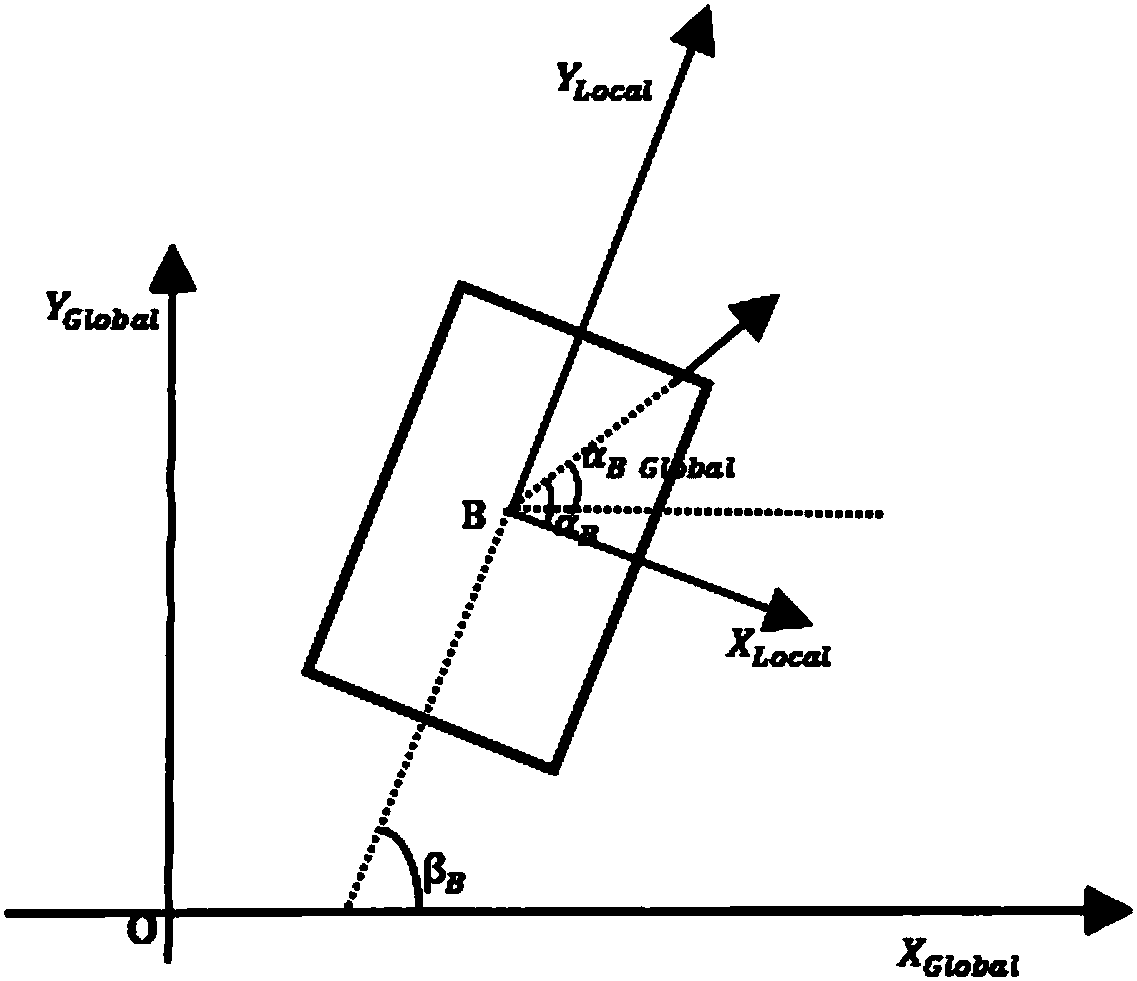

[0035] In the present invention, the position, speed, and posture of the wheeled robot are collectively called the full state of the wheeled robot. The wheeled robot can independently control the speed and direction at the same time. The process of state transition to a known target full state is divided into three stages. In order to solve the problem that the final velocity direction is inconsistent with the initial and final position vector directions during the initial and final full state changes, different from the traditional method that requires a wider space to cut in the velocity direction, this method can be used in a relatively narrow space Any full state change in the environment; on the other hand, this method can change the attitude, speed, and position synchronously, which is different from the currently wide...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com