Matching calculation method for centrifugal impeller and diffuser under pre-swirl air intake condition

A technology of centrifugal impeller and matching calculation, which is applied in the fields of calculation, instrument, special data processing application, etc., can solve the problems of matching research between centrifugal impeller and diffuser, etc., and achieve the effect of wide stable working condition range and high entropy efficiency.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific example

[0065] This example combines the design and matching process of an industrial pressure-sonic centrifugal compressor to demonstrate the matching calculation method of the centrifugal impeller and the diffuser under the pre-rotation air intake:

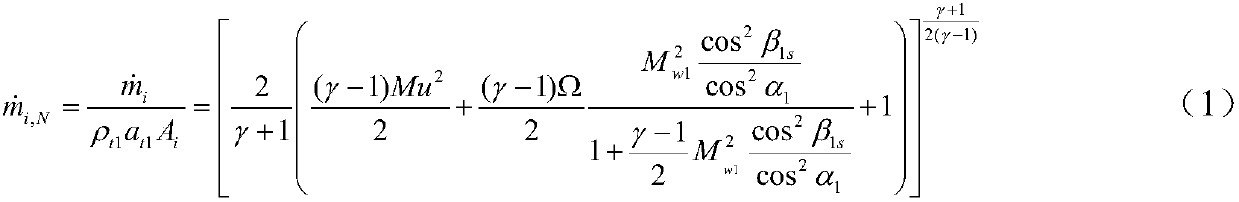

[0066] 1) Given air medium characteristic parameters: adiabatic index γ=1.4, gas constant R=287J / (kg k); given centrifugal impeller design parameters: centrifugal impeller inlet pre-rotation angle α 1 =30deg, the relative axial airflow angle β of the centrifugal impeller inlet wheel cover 1s =39.8deg, the relative Mach number M of the inlet wheel cover of the centrifugal impeller w1 =0.5114, the total pressure ratio ε=2.0

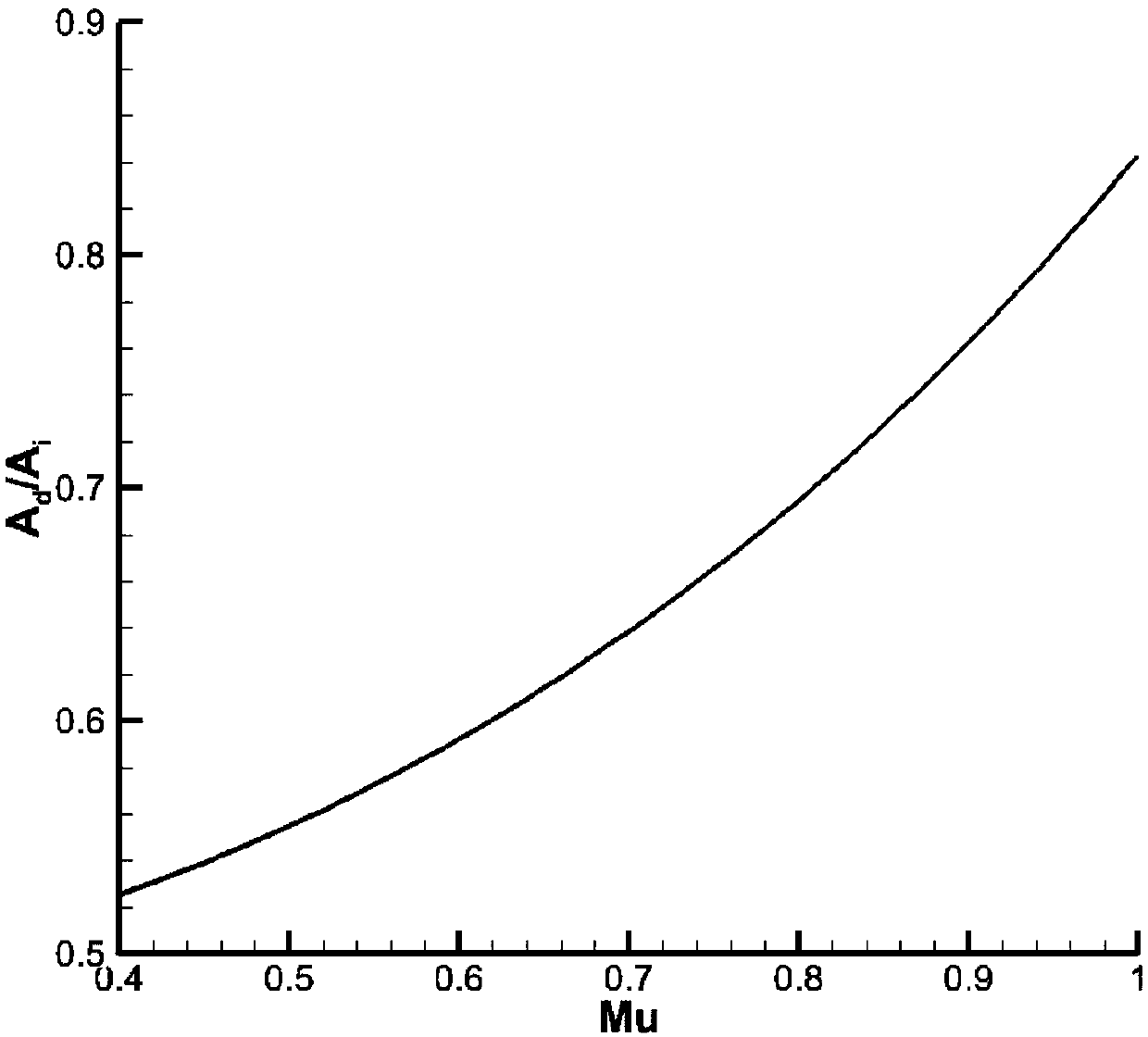

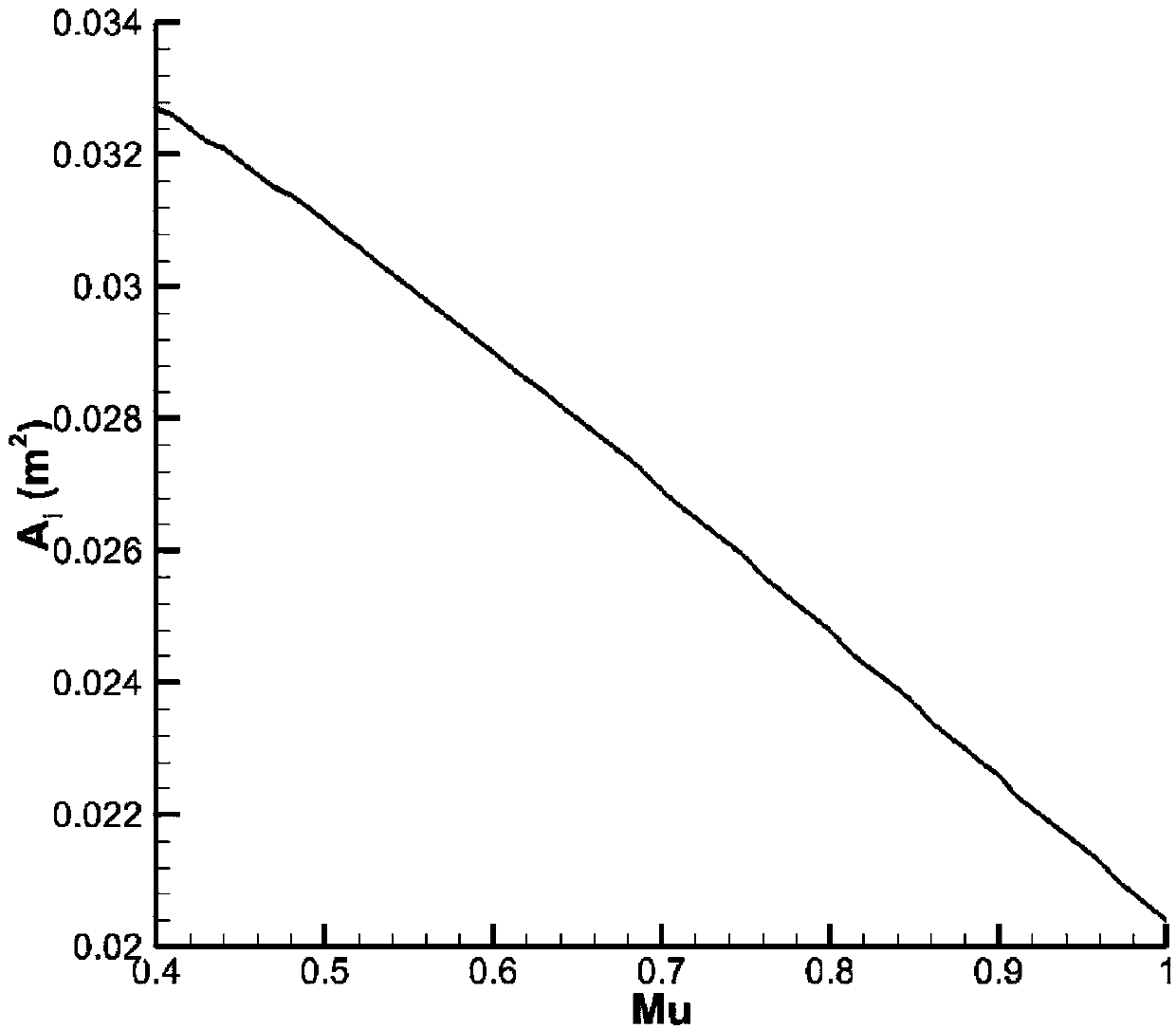

[0067] 2) Calculate the normalized impeller blocking flow according to the formula (1) of the present invention

[0068]

[0069] Normalized impeller blocking flow It is a function of the local machine Mach number Mu, which essentially reflects that the area of the blocked throat of the centrifugal impeller changes along...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com