Device capable of adopting secondary flow mechanism and improving non-azeotropic working medium Rankine cycle efficiency

A Rankine cycle and secondary flow technology, applied in steam engine installations, mechanical equipment, machines/engines, etc., can solve the problems of hindering the condensation of low-boiling point gases, increasing the resistance of mass transfer and heat transfer, and increasing the temperature of the gas-liquid interface. Overcome mass transfer and heat transfer resistance, enhance mixing, and reduce the effect of expansion ratio

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0028] Hereinafter, the present invention will be described in detail through specific embodiments in conjunction with the accompanying drawings.

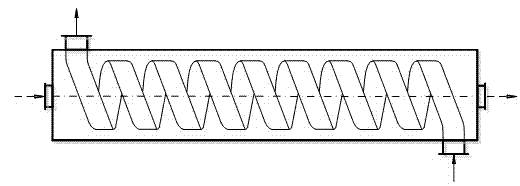

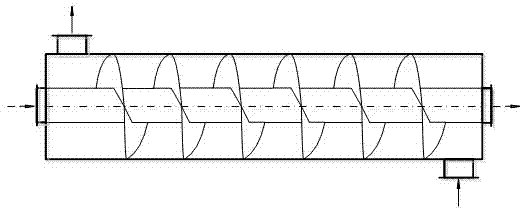

[0029] The steam generator 1 in this circulation device adopts a single-spiral heat exchanger, and the non-azeotropic mixed working medium is selected from two components, and the composition ratio of the refrigerant R152a:R245fa is 0.3:0.7.

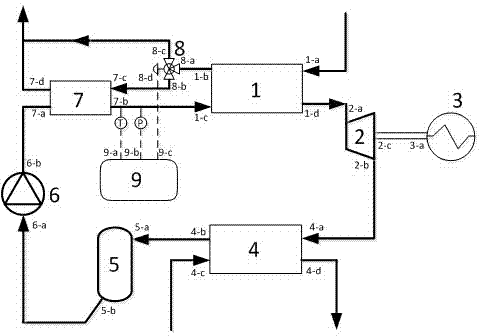

[0030] like figure 1 As shown in , 2, the present invention is a device for improving the efficiency of the non-azeotropic working fluid Rankine cycle by using a secondary flow mechanism, including a steam generator 1, this embodiment adopts a single-spiral steam generator, an expander 2, and a generator 3 , condenser 4, accumulator 5, working fluid pump 6, preheater 7, three-way valve 8, control mechanism 9; The first outlet 2-c of the expander is connected to the inlet 3-a of the generator, and the second outlet 2-b of the expander is connected to the refrigerant inlet of the condenser 4-...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com