Bearing assembly, compressor and heat pump equipment

A technology of bearing components and compressors, which is applied in the direction of mechanical equipment, pumps, pump components, etc., can solve the problems of low air injection volume and insufficient effect of improving the low-temperature heating capacity of compressors, so as to achieve sufficient air injection volume, reduce production costs, The effect of improving the heating capacity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

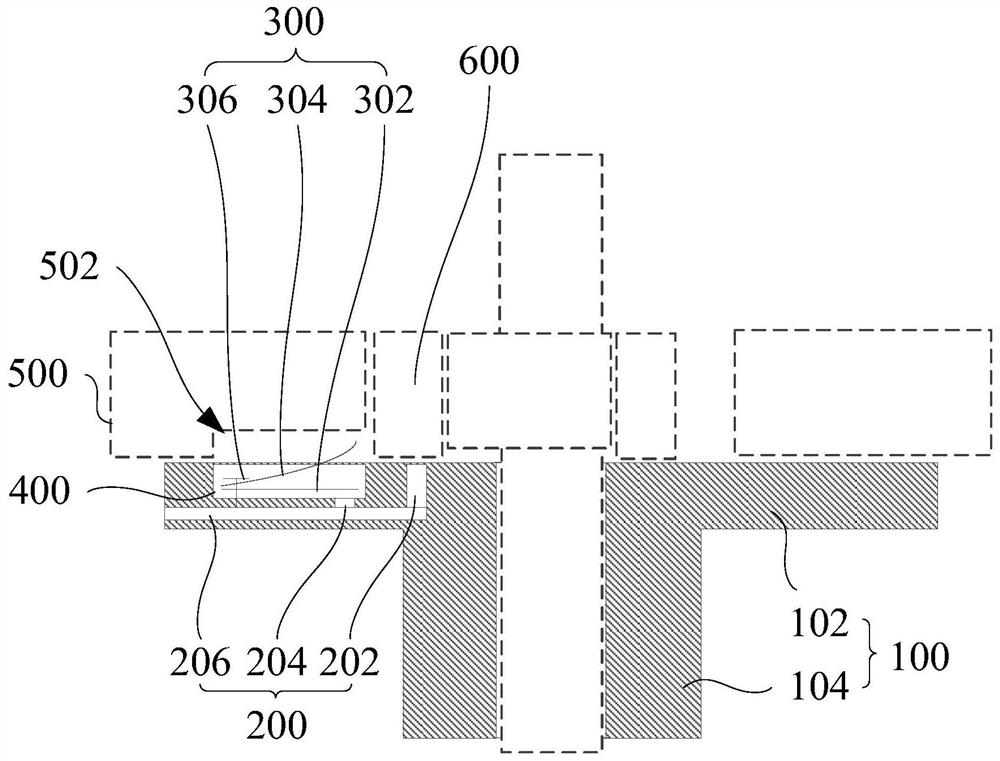

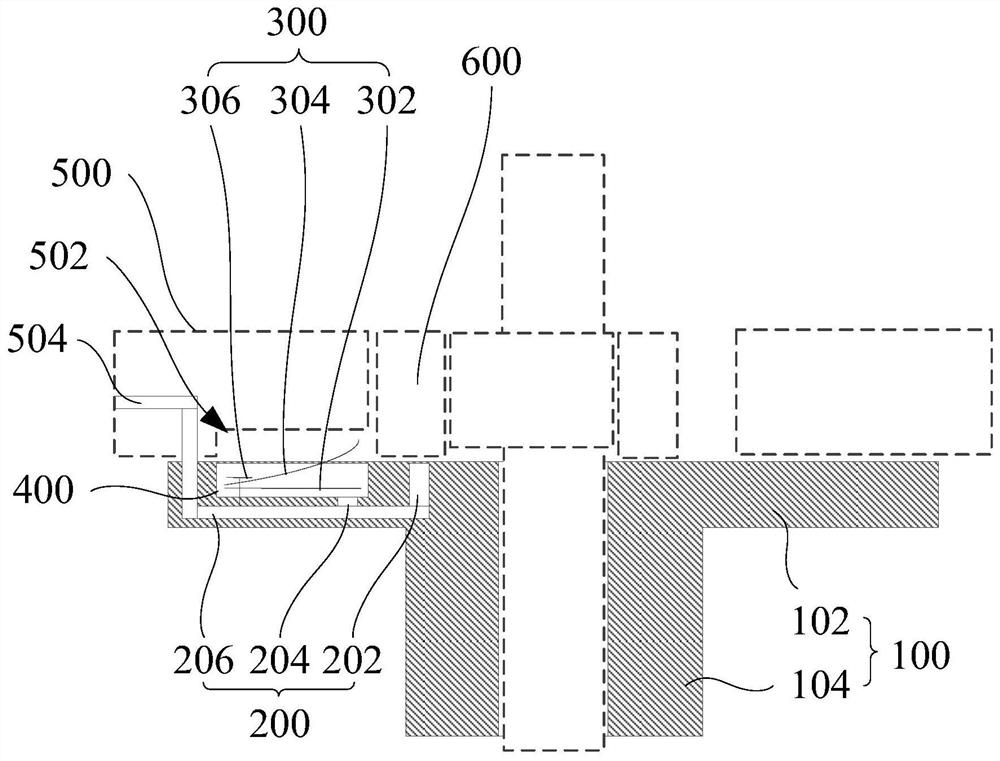

[0068] The embodiment of the first aspect of the present invention provides a bearing assembly for a compressor. Such as figure 1 As shown, the bearing assembly includes a bearing 100 and an air injection channel 200 . Wherein, the air injection channel 200 is arranged on the bearing 100, and the air injection channel 200 includes at least two air injection sub-channels, and the at least two air injection sub-channels can communicate with the exhaust chamber of the compressor.

[0069] The bearing assembly provided by the embodiment of the present invention can use the air injection channel 200 to deliver the medium-pressure gas to the exhaust chamber of the compressor by opening the air injection channel 200 on the bearing 100, thereby reducing the exhaust temperature of the compressor, and at the same time can Improve the heating capacity of heat pump equipment using the compressor under low temperature conditions. Since the bearing 100 is only a part of the compressor, by...

Embodiment 2

[0074] On the basis of Embodiment 1, this embodiment describes the plugging structure of the air injection channel 200. Further, at least two air injection sub-channels include the first air injection sub-channel 202 and the second air injection sub-channel 204, and the first air injection sub-channel 204 The jet end of the channel 202 can be blocked by the piston 600 of the compressor; the bearing assembly also includes a check valve 300 , which is arranged on the bearing 100 , and the check valve 300 can block the jet end of the second jet sub-channel 204 .

[0075] In this embodiment, the at least two air injection sub-channels specifically include the first air injection sub-channel 202 and the second air injection sub-channel 204 that are blocked in different ways, so as to form different air injection mechanisms. It is worth noting that, for the jet sub-channel, the jet sub-channel includes the intake end and the jet end, and the intake end of the jet sub-channel can be d...

Embodiment 3

[0092] On the basis of Embodiment 1 or Embodiment 2, Embodiment 3 provides a bearing assembly. The bearing 100 includes a first bearing segment 102 and a second bearing segment 104 distributed along the axial direction. The outer diameter of the first bearing segment 102 is Larger than the outer diameter of the second bearing segment 104 , the jet ends of at least two jet sub-channels extend to the end surface of the first bearing segment 102 away from the second bearing segment 104 .

[0093] In this embodiment, the bearing 100 specifically includes a first bearing section 102 and a second bearing section 104 with a large outer diameter and a smaller outer diameter. The first bearing section 102 with a larger outer diameter can take on the role of a flange, and is compatible with the compressor. The cylinders 500 are connected, and the end surface of the first bearing section 102 away from the second bearing section 104 is the end surface of the bearing 100 corresponding to th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com