Opthalmological optical element and method for constructing opthalmological optical element

A technology of optical elements and diffractive optical elements, applied in the field of ophthalmic optical elements, can solve problems such as chromatic aberration, and achieve the effect of reducing material and weight

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

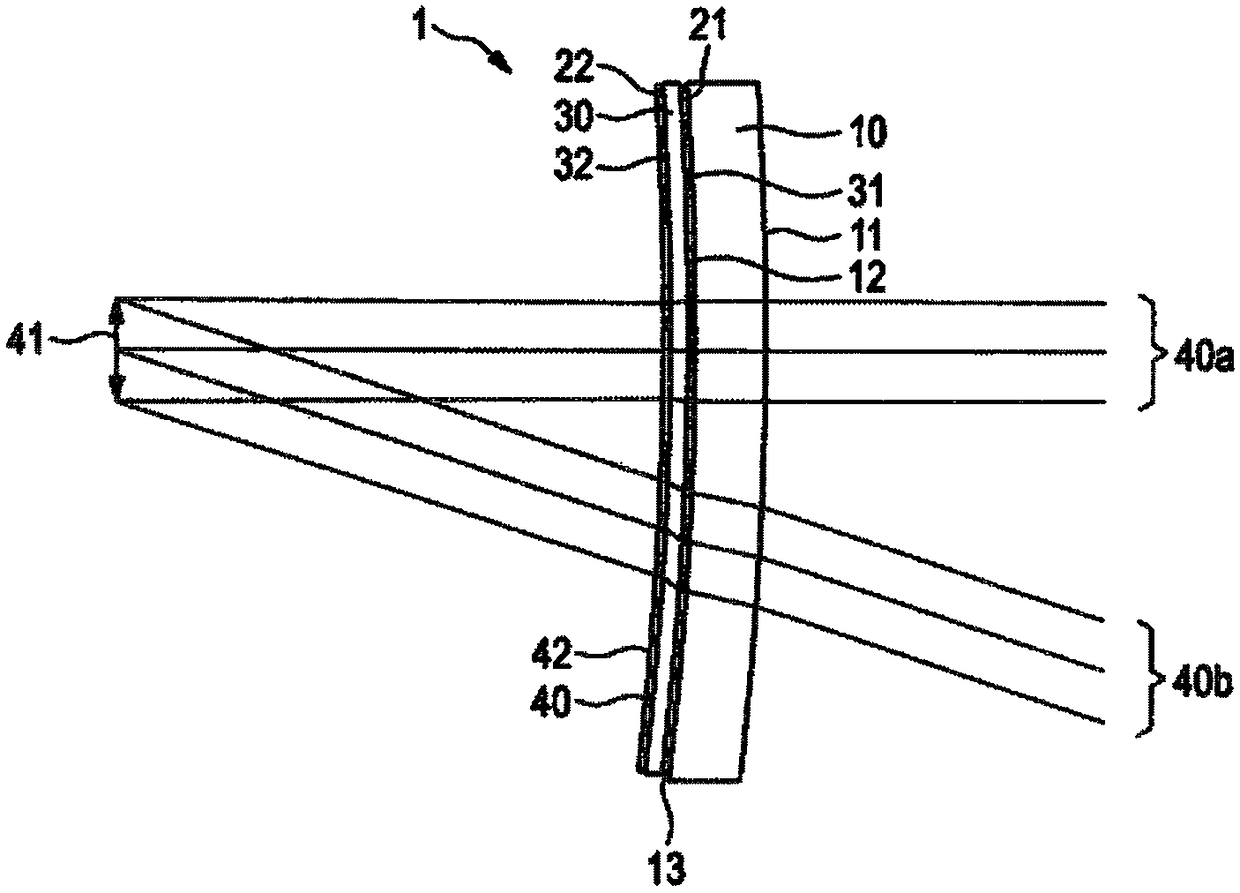

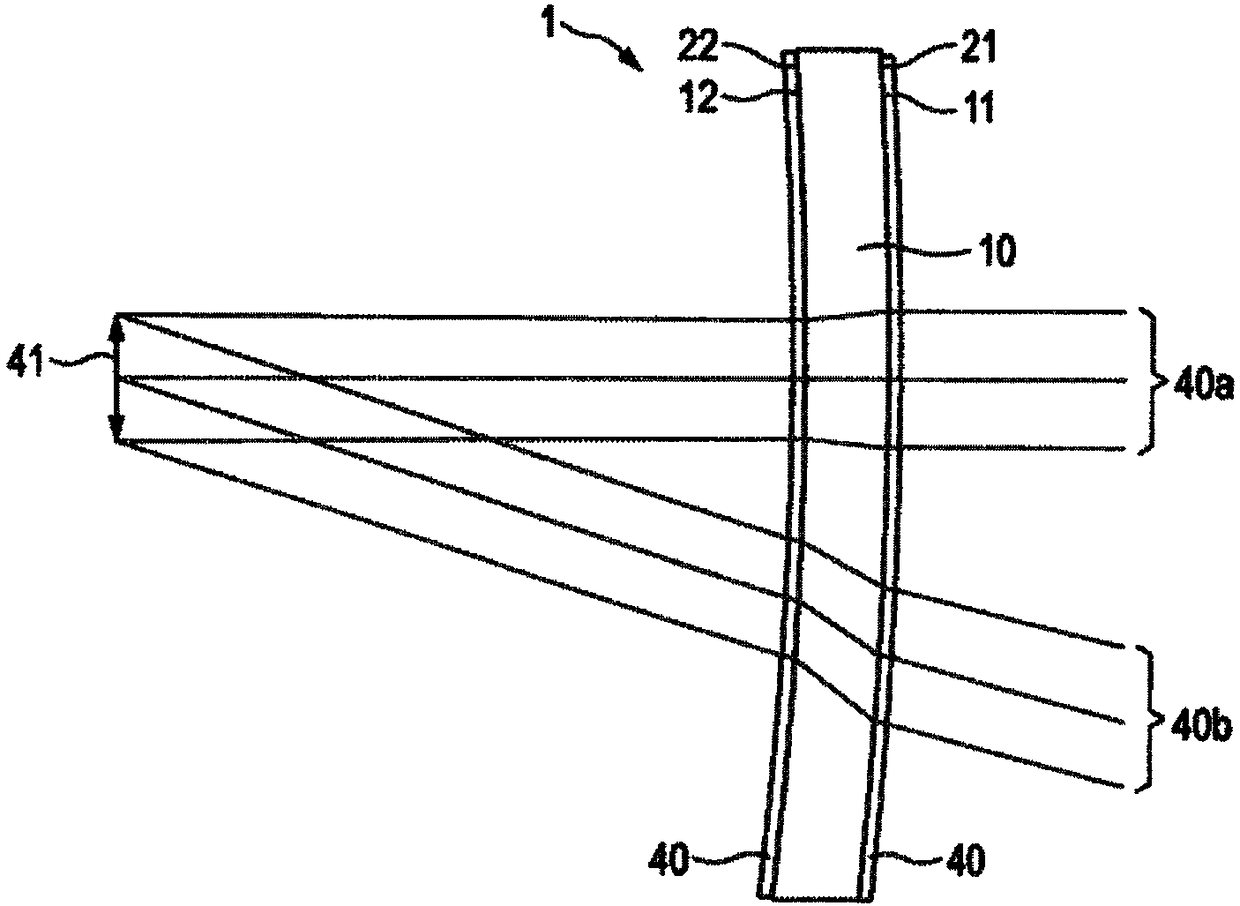

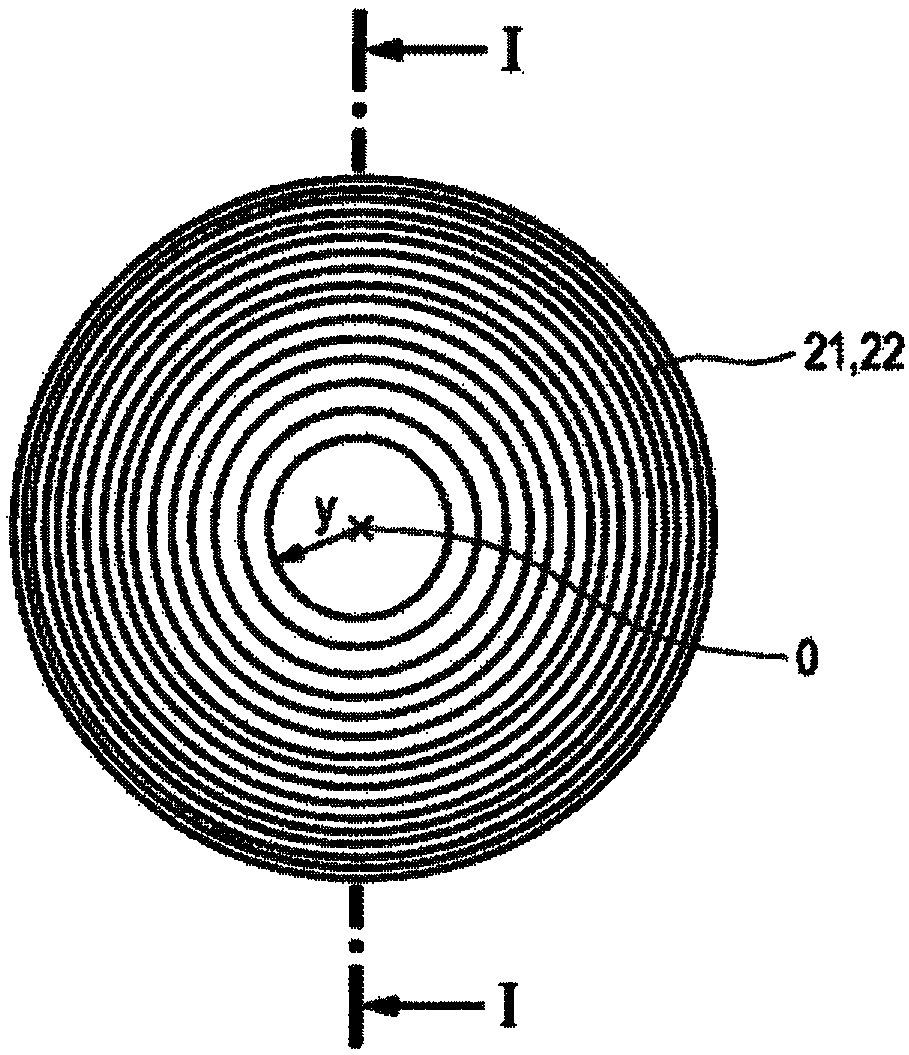

[0101] figure 1 A cross-sectional illustration of an ophthalmic optical element 1 , eg a spectacle lens, according to a first embodiment is shown. The ophthalmic optical element 1 has: a first refractive optical substrate 10, the first refractive optical substrate has a positive or negative first power; a first diffractive optical element (DOE) 21, the first diffractive optical element having a second optical power; and a second diffractive optical element 22 having a third optical power, wherein the first diffractive optical element 21 and the second diffractive optical element 22 have opposite optical powers, And wherein the first diffractive optical element 21 and the second diffractive optical element 22 interact in an at least partially achromatic manner. The first diffractive optical element 21 and the second diffractive optical element 22 may have approximately the same power in absolute value, but with opposite signs, and thus the first diffractive optical element 21...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com