Novel non-fried noodle production process

A non-fried noodle and production process technology, applied in the field of food processing, can solve problems such as high labor intensity, low speed efficiency, and difficulty in matching equipment speed, so as to reduce labor intensity, uniform humidity, improve drying efficiency and product quality Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

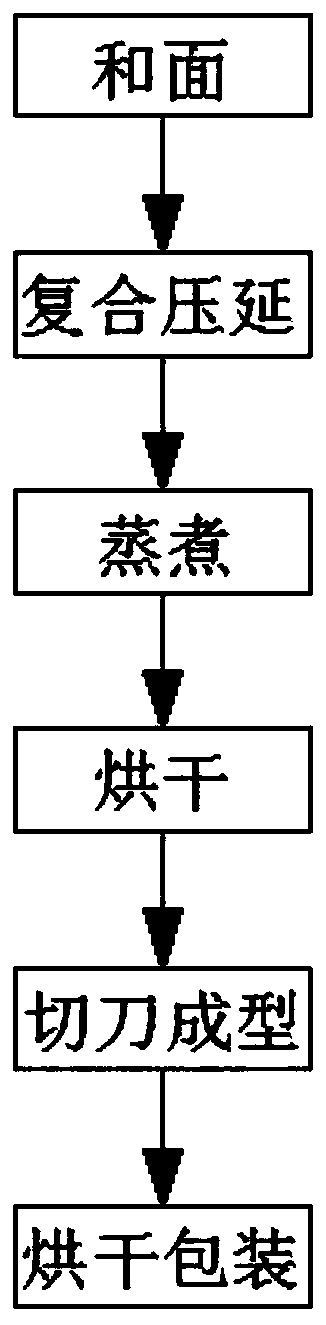

[0021] This novel non-fried noodle production technique comprises the steps:

[0022] S1: Kneading dough: put the raw materials and ingredients into a vacuum dough kneading machine with a vacuum degree of 500-600 mmHg, and knead the dough. The stirring rate of the vacuum kneading machine is 400 rpm, and the stirring time is 60 minutes;

[0023] S2: Composite calendering: In the calender, two noodle strips are respectively rolled by corrugated rollers to form two noodle strips, and then compounded to form one noodle strip. The calendered thickness of the noodle strips is 0.8 mm;

[0024] S3: Steaming: put the noodle strips in step S2 into a cooking box for cooking, the cooking time is 20 minutes, and the cooking temperature is 70 degrees Celsius;

[0025] S4: Drying: use a hot air blower to dry the surface of the noodle belt to remove the moisture on the surface of the noodle belt;

[0026] S5: Cutter forming: the noodle strip is cut into 2.5mm noodles by a vertical cutter, an...

Embodiment 2

[0029] This novel non-fried noodle production technique comprises the steps:

[0030] S1: Kneading dough: Put the raw materials and ingredients into a vacuum dough kneading machine with a vacuum degree of 500-600 mmHg to knead the dough. The stirring rate of the vacuum kneading machine is 600 rpm, and the stirring time is 80 minutes;

[0031] S2: Composite calendering: In the calender, two noodle strips are formed after being rolled by corrugated rollers, and then compounded to form one noodle strip. The calendered thickness of the noodle strips is 1.0 mm;

[0032] S3: Steaming: put the noodle strips in step S2 into a cooking box for cooking, the cooking time is 30 minutes, and the cooking temperature is 80 degrees Celsius;

[0033] S4: Drying: use a hot air blower to dry the surface of the noodle belt to remove the moisture on the surface of the noodle belt;

[0034] S5: Cutter forming: the noodle strip is cut into 2.5mm noodles by a vertical cutter, and then the noodles are...

Embodiment 3

[0037] This novel non-fried noodle production technique comprises the steps:

[0038] S1: Kneading dough: put the raw materials and ingredients into a vacuum dough kneading machine with a vacuum degree of 500-600 mmHg, and knead the dough. The stirring speed of the vacuum kneading machine is 500 rpm, and the stirring time is 70 minutes;

[0039] S2: Composite calendering: In the calender, two noodle bands are formed after being rolled by corrugated rollers respectively, and then compounded to form a noodle band, and the calendered thickness of the noodle bands is 0.9 mm;

[0040] S3: Steaming: put the noodles in step S2 into a steaming box for steaming, the cooking time is 25 minutes, and the cooking temperature is 75 degrees Celsius;

[0041] S4: Drying: use a hot air blower to dry the surface of the noodle belt to remove the moisture on the surface of the noodle belt;

[0042] S5: Cutter forming: the noodle strip is cut into 2.5 mm noodles by a vertical cutter, and then the...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com