Laminating machine and gluing device thereof

A gluing device and gluing technology, which is applied to the device for coating liquid on the surface, paper, paper making, etc. The effect of efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

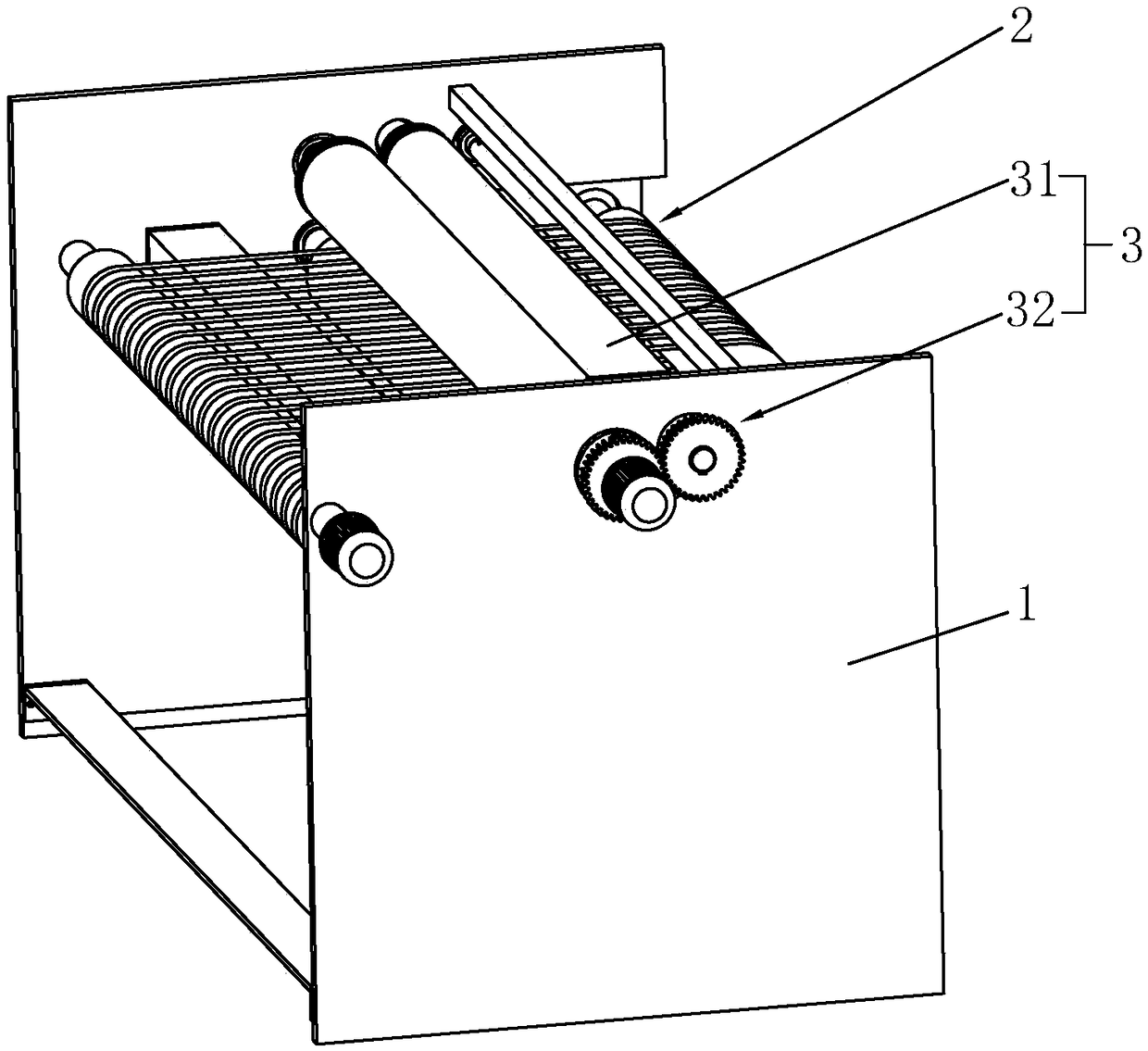

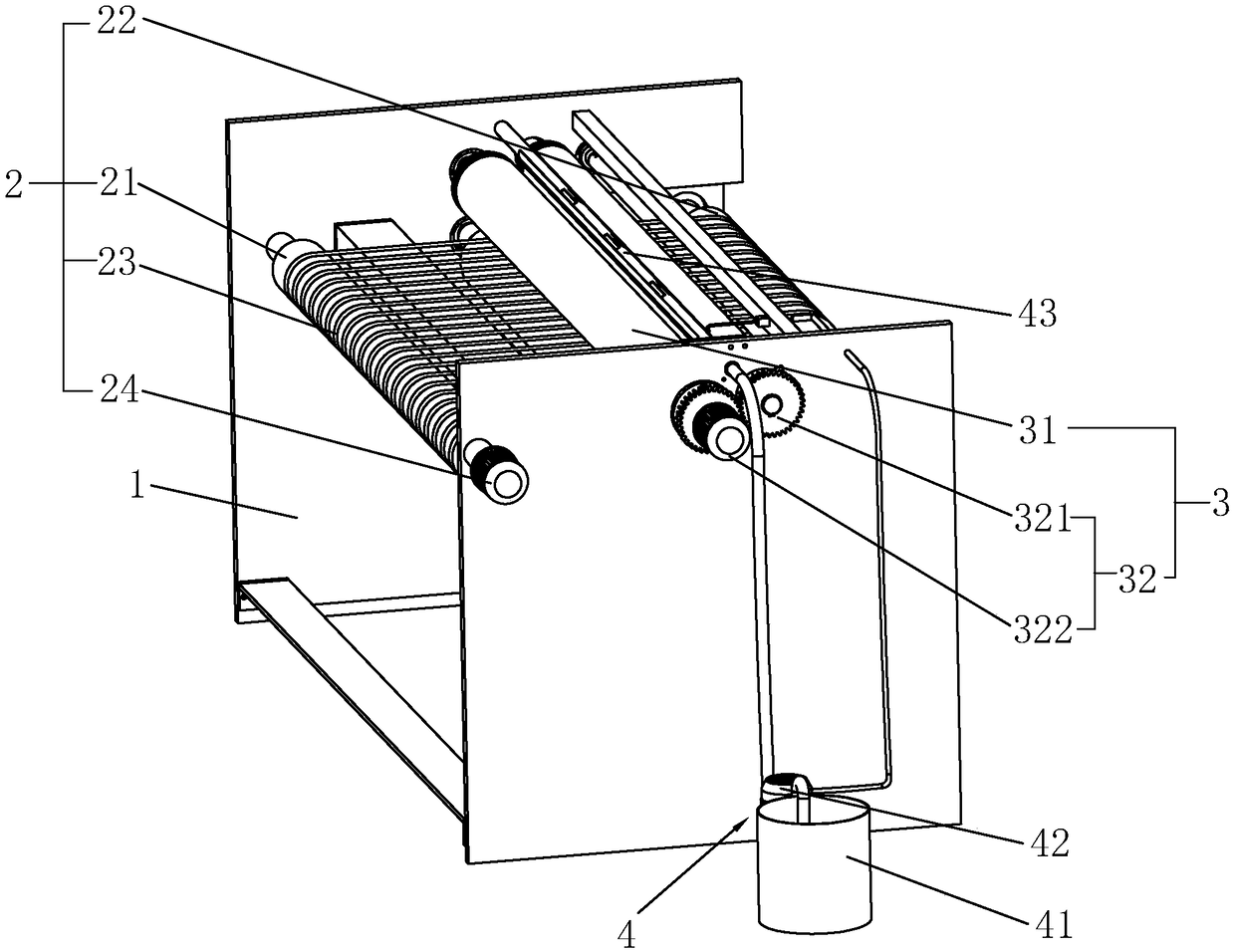

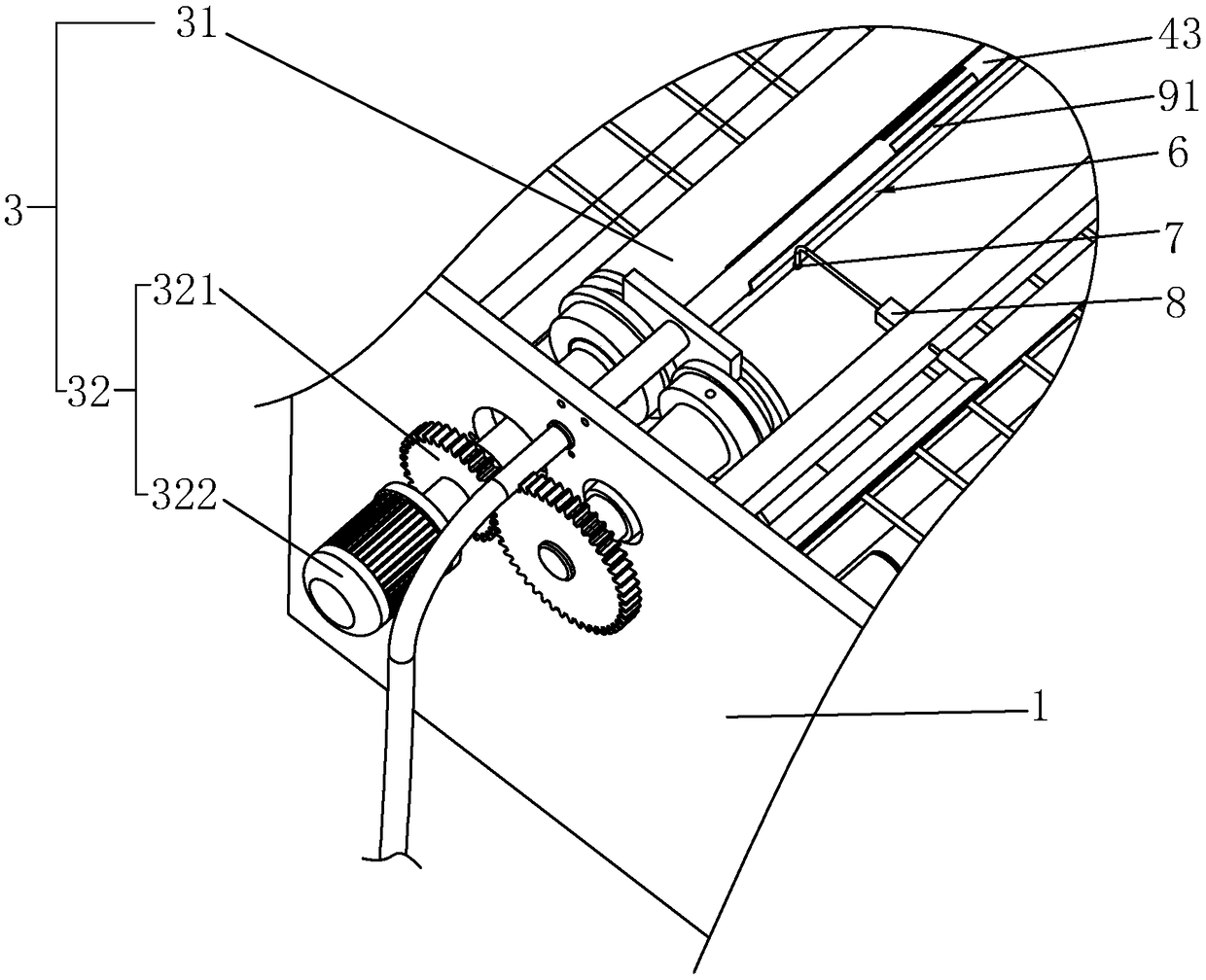

[0035] A gluing device, such as figure 2 As shown, it includes a frame 1 , a paper transport mechanism 2 , a gluing mechanism 3 and a glue feeding device 4 . The paper conveying mechanism 2 is arranged on the frame 1 and used for conveying the paper. The gluing mechanism 3 is installed on the frame 1 and located above the paper conveying mechanism 2 , and the gluing mechanism 3 is used for gluing the paper on the paper conveying mechanism 2 . The glue feeding device 4 is arranged on the frame 1 and is opposite to the glue applying mechanism 3 , and the glue sending device 4 is used for automatically injecting glue into the glue applying mechanism 3 .

[0036]The paper transport mechanism 2 includes a driving roller 21 , a driven roller 22 , a conveyor belt 23 and an actuator motor 24 . The driving roller 21 is rotatably connected to the frame 1, and the rotation axis of the driving roller 21 is perpendicular to the conveying direction of the paper. The driven roller 22 is ...

Embodiment 2

[0045] A laminating machine, such as Figure 5 As shown, the gluing device as described in the first embodiment is included.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com