Automatic gear spring press-fitting machine for car tail door lock production line

A technology of locking production lines and press-fitting machines, applied in metal processing, metal processing equipment, manufacturing tools, etc., can solve the problems of labor-intensive, low work efficiency, time-consuming and labor-intensive, etc., achieve the effect of reasonable design and avoid cost waste

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

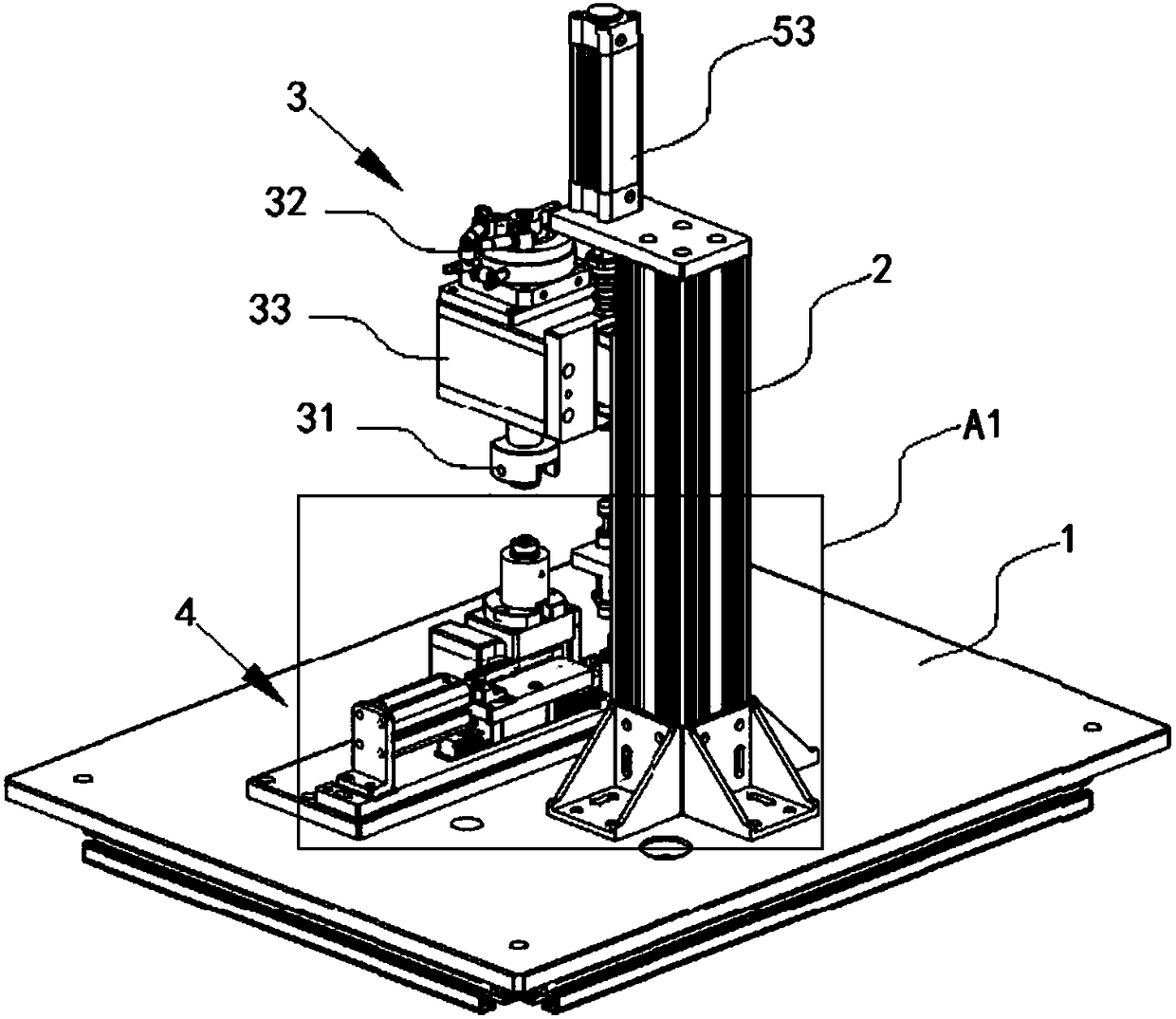

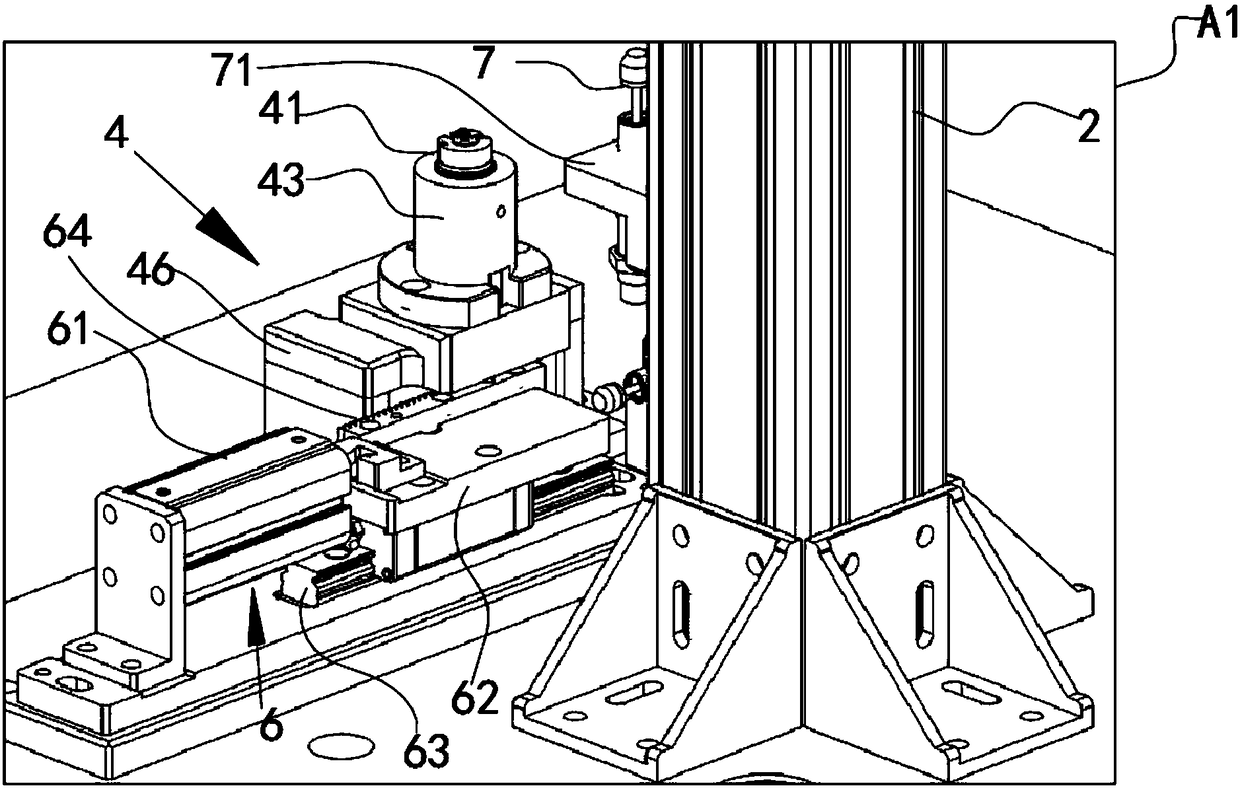

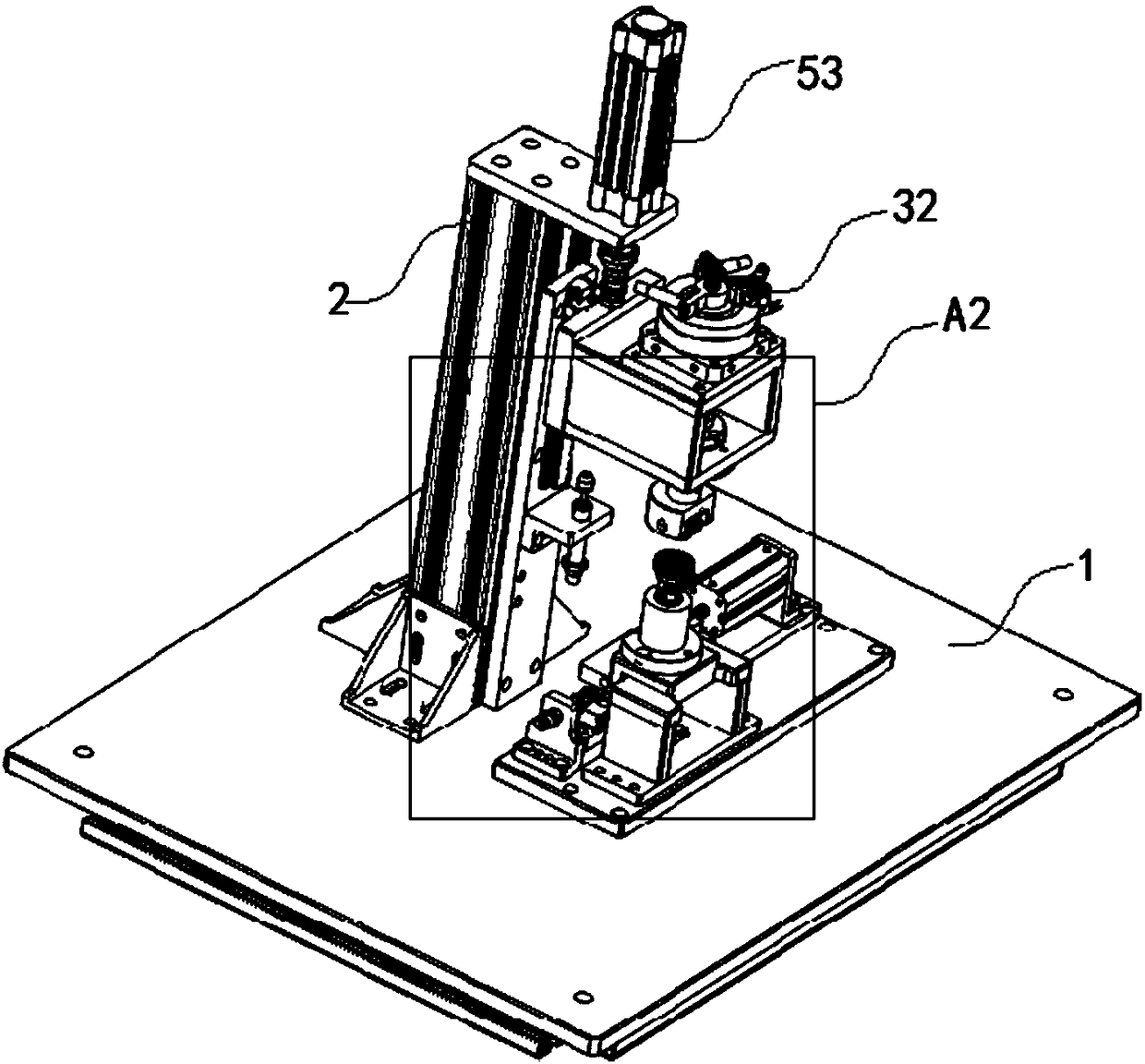

[0031] Embodiment: a kind of gear spring automatic pressing machine for automobile tailgate lock production line, such as Figure 1-Figure 8 As shown, it includes a press-fitting station, a base 1 and a support 2, the press-fitting station includes an upper pressing mechanism 3 and a spring bearing mechanism 4, the upper pressing mechanism is connected to the bracket, and the spring bearing mechanism is installed on the base, The upper pressing mechanism includes a pressure head 31 and a rotary cylinder 32 that drives the pressure head to rotate, the rotary cylinder is fixedly connected above the pressure head and the lower end of the rotary cylinder is connected to the pressure head;

[0032] Also be provided with the lifting unit that drives described upper pressing mechanism to move up and down, described lifting unit comprises lifting slider 51, lifting track 52 and lifting cylinder 53, will be provided with the side that press-fitting station is defined as the front, descr...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com