Assembling clamp for hole drilling of rod-like object

A technology for long strips and objects, which is applied in the field of clamping fixtures for drilling long strips of objects. It can solve problems such as poor operation effect, difficult centering positioning, and low efficiency, and achieves extended service life, easy lifting, and stable lifting. sexual effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0030] The principles and features of the present invention are described below in conjunction with the accompanying drawings, and the examples given are only used to explain the present invention, and are not intended to limit the scope of the present invention.

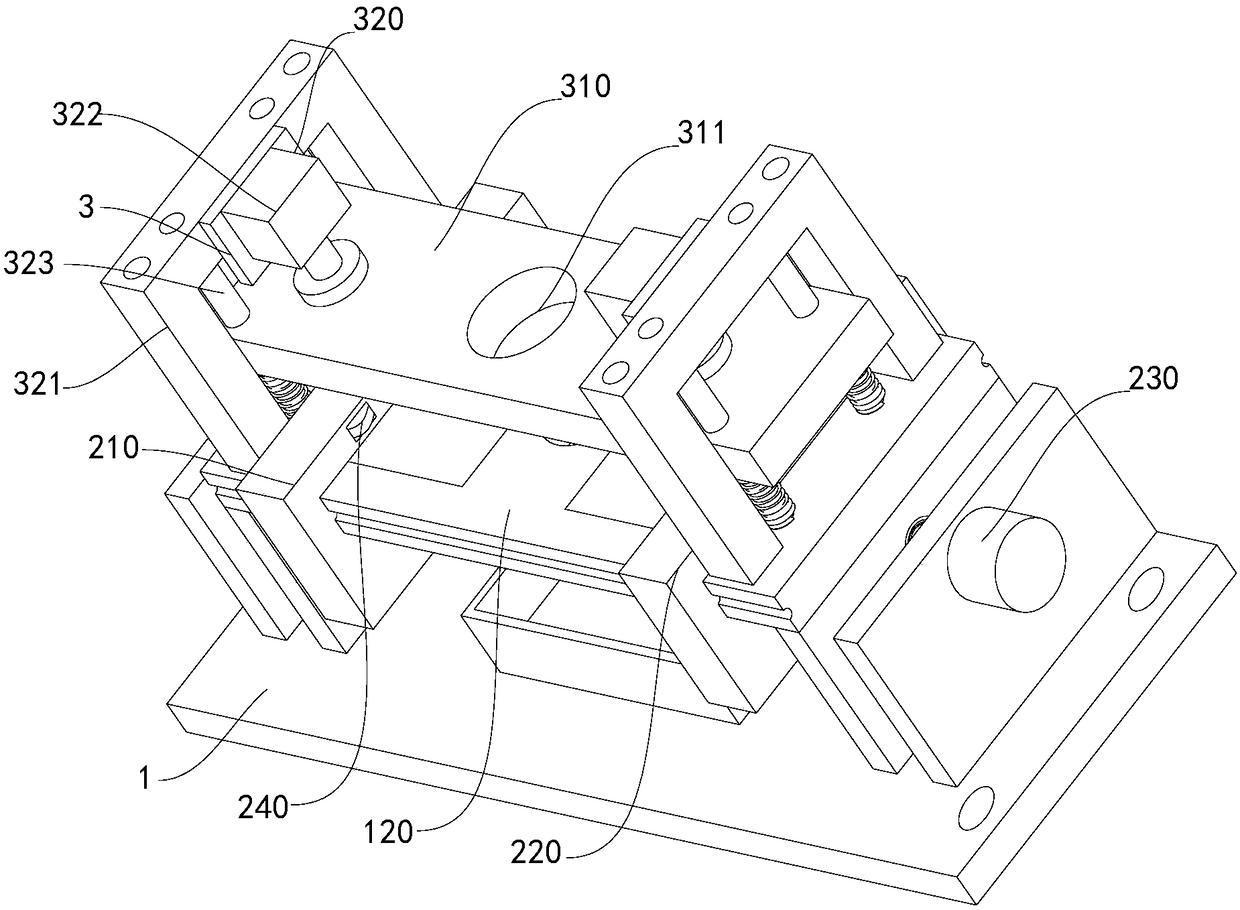

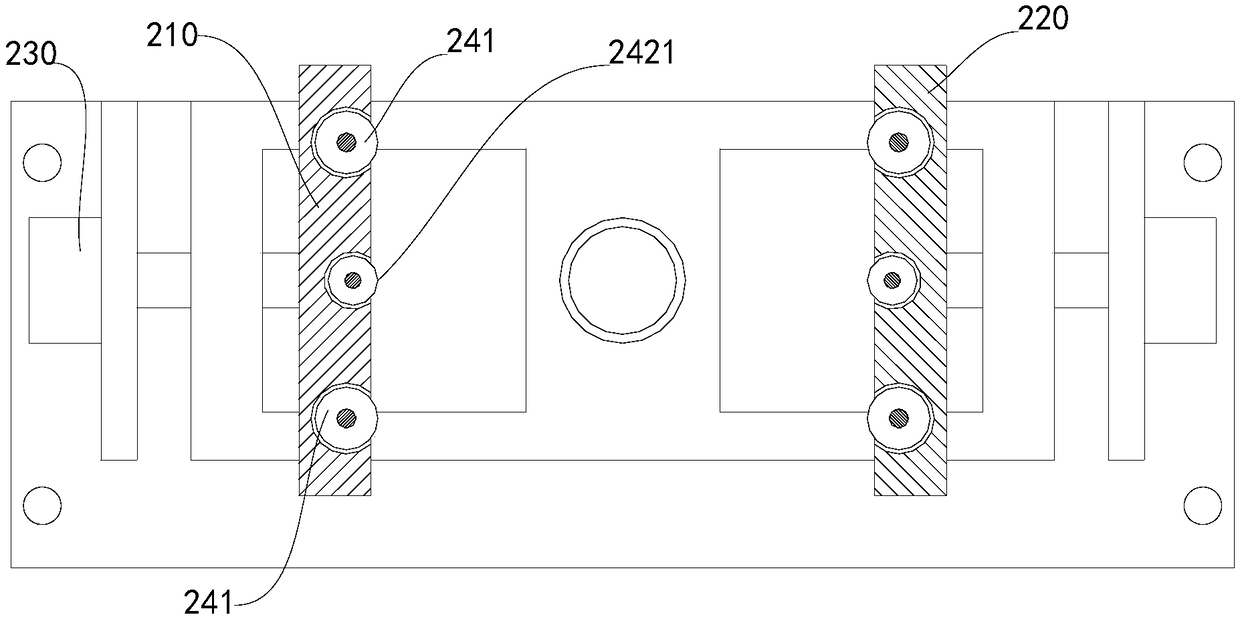

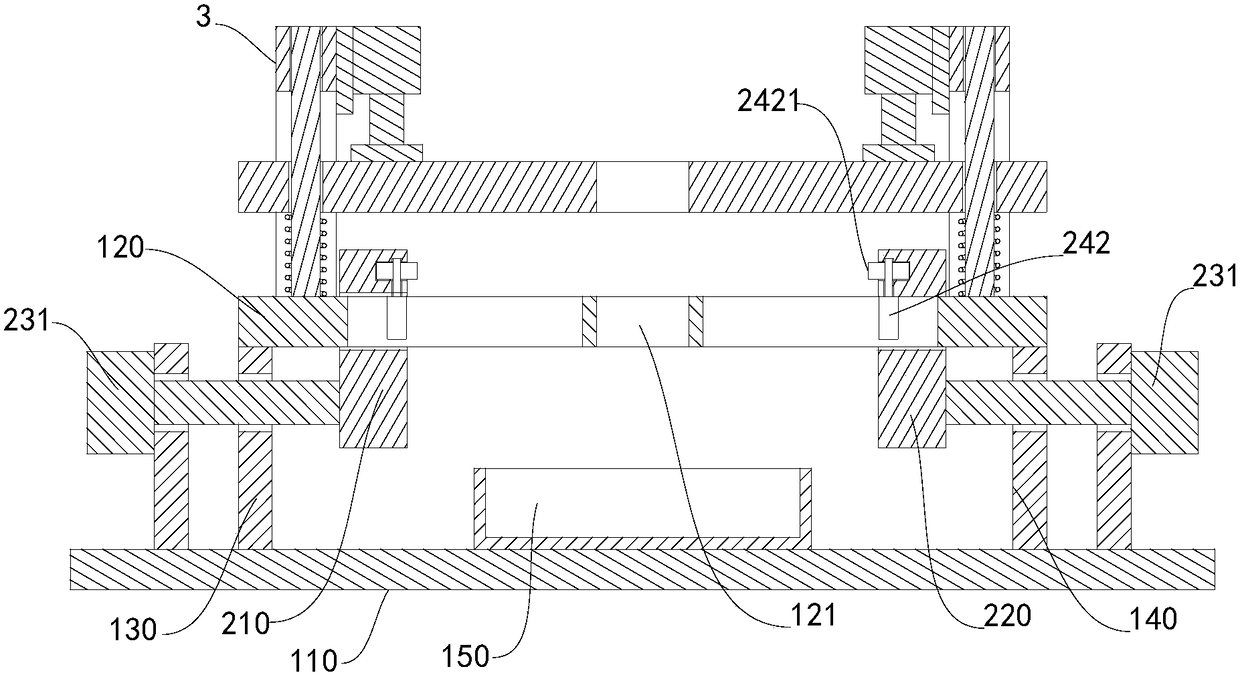

[0031] like figure 1 , figure 2 , image 3 As shown, a clamping jig for drilling a strip-shaped object includes a base 1 and an alignment mechanism 2, wherein the alignment mechanism 2 includes a first clamping block 210, a second clamping block 220, a first adjustment assembly 230 and The length measuring assembly 240, the first adjusting assembly 230 is arranged on the base 1, the first clamping block 210 is arranged on the first adjusting assembly 230, the second clamping block 220 is arranged on the first adjusting assembly 230, the first adjusting assembly 230 can Let the first clamping block 210 and the second clamping block 220 approach and move away from each other in the horizontal direction. On the sid...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com