A demolition blasting test blasting method

A test explosion, consistent technology, applied in the direction of blasting, can solve the problems of poor safety, difficult to achieve ideal results, increased workload, etc., to achieve the effect of small amount of engineering, obvious test explosion situation, easy to observe

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0027] The present invention will be further described in detail below in conjunction with the accompanying drawings and specific embodiments.

[0028] A certain place wants to demolish an old factory building by blasting. In the early stage of design work, it is necessary to determine the usage of explosives for demolition construction. Therefore, it is necessary to conduct a test blast to determine the amount of explosives.

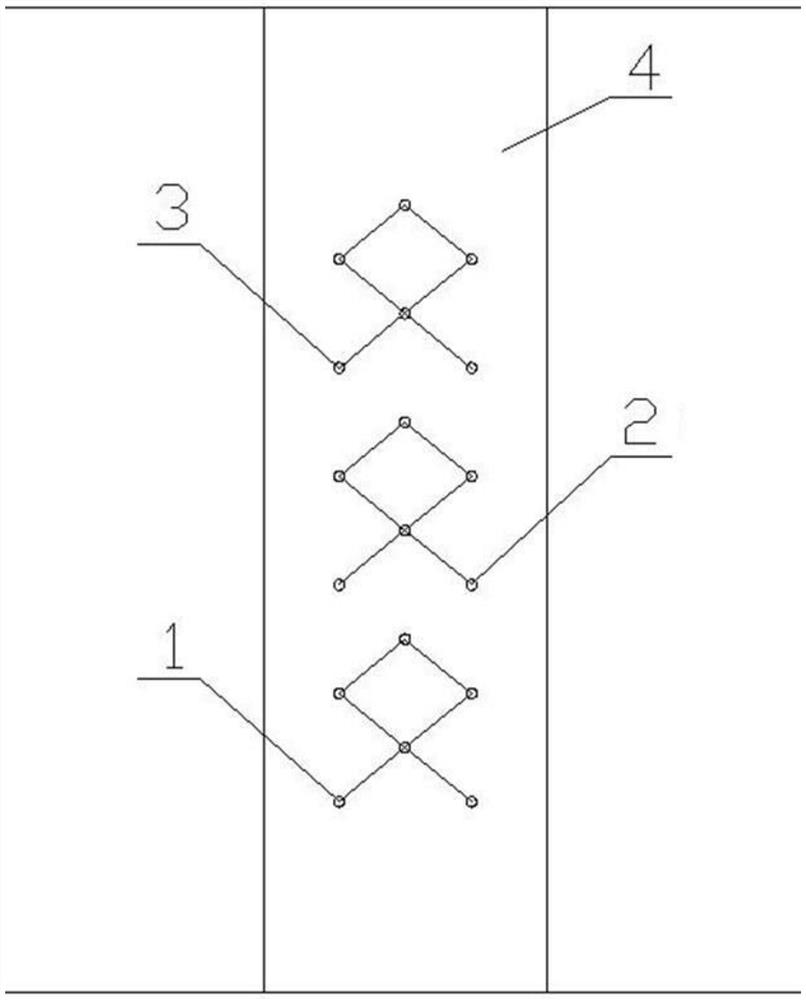

[0029] Before the explosion test, it is necessary to select a component in the factory building as the explosion test component. The principle of selection is that the component will not affect the structural stability of the factory building after being broken by blasting. According to the structural characteristics of the factory building, the column 4 in the factory building is selected as the blasting test component.

[0030] Such as figure 1 As shown, the blasting test holes are drilled on the column 4. In this embodiment, three groups of blasting...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com