Ultrasonic detection method for bonding defects of web and girder after mold clamping of wind power generation blades

A technology for wind power generation blades and detection methods, which is applied in the direction of using sound waves/ultrasonic waves/infrasonic waves to analyze solids, instruments, and analysis materials, etc., which can solve the problem of affecting the mechanical properties and integrity of blades, reducing the working life of blades, large dispersion of product quality, etc. problems, to achieve the effect of improving monitorability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment

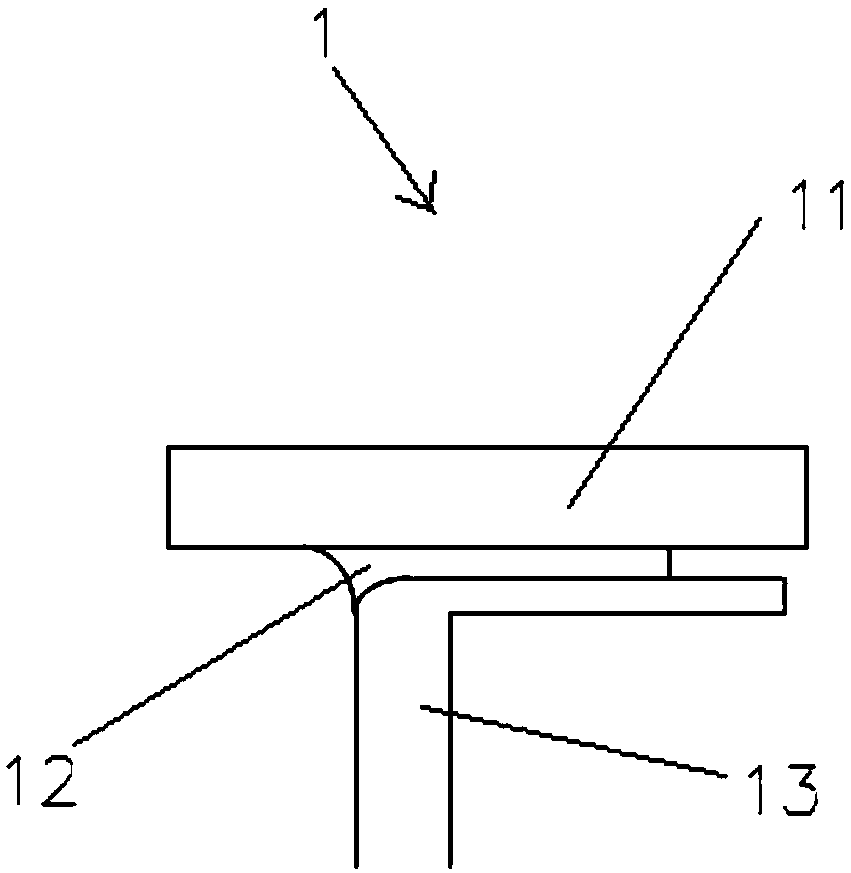

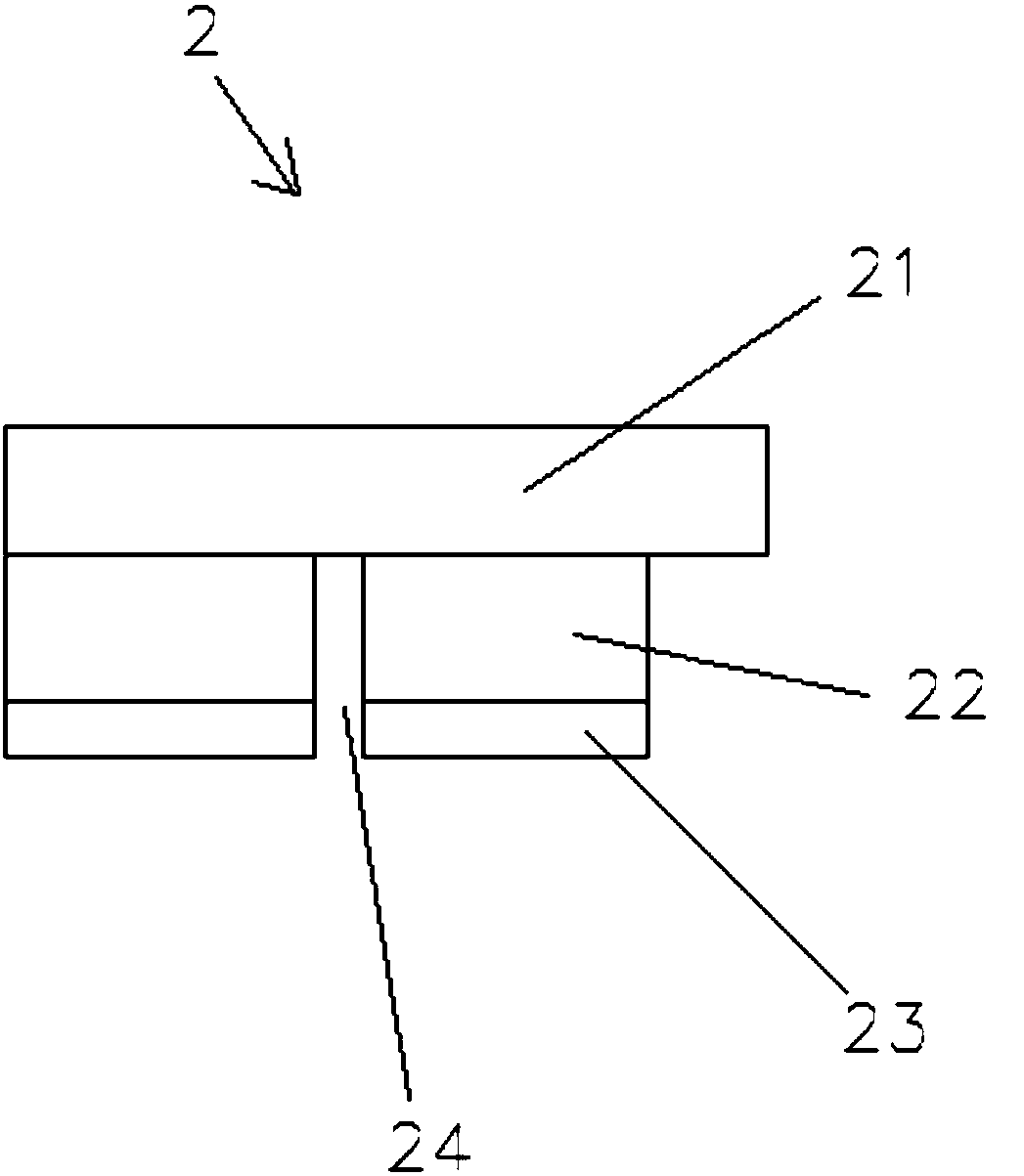

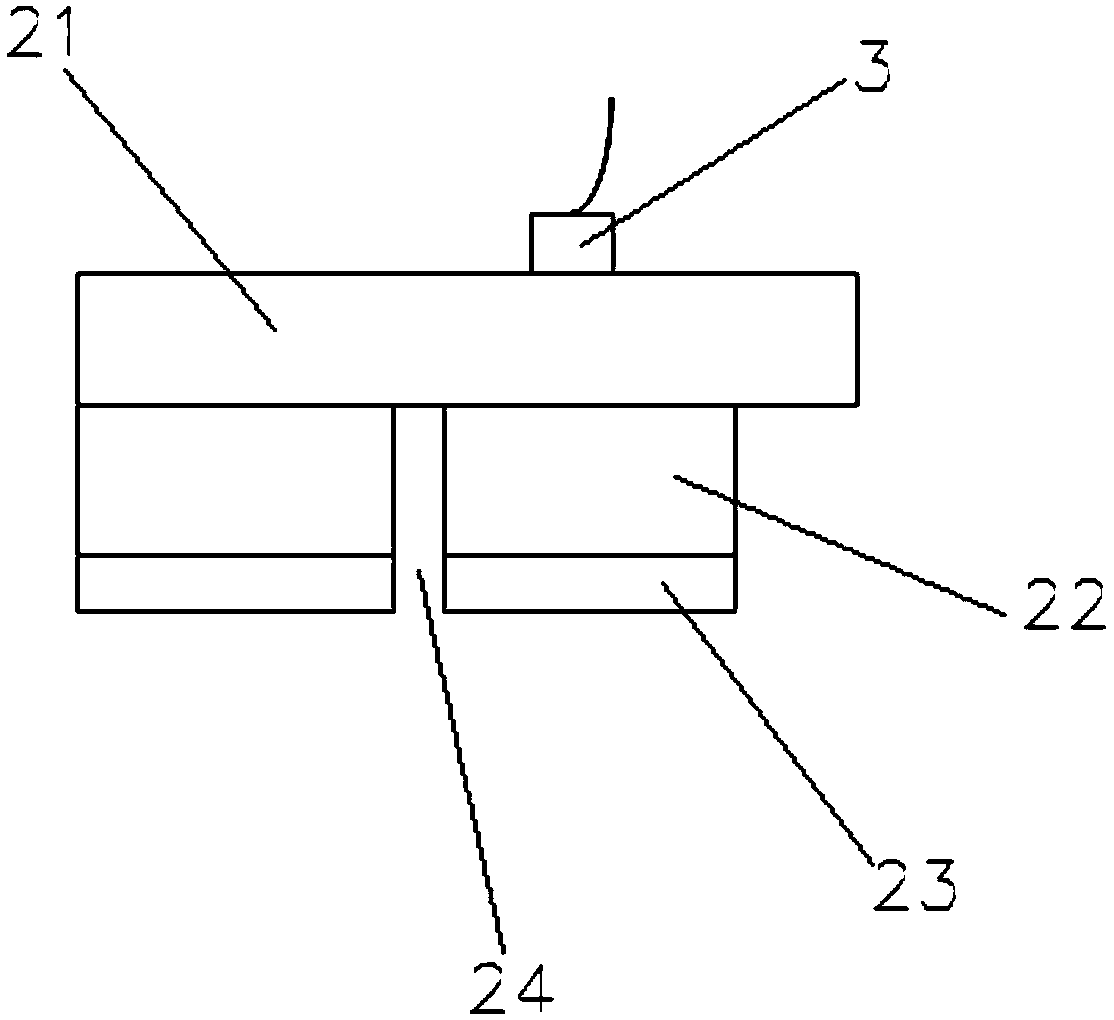

[0034] Specific embodiment: the web to be inspected and the beam bonding workpiece 1 ( figure 1 shown) includes a blade shell 11, an adhesive layer 12, and a web 13, and the blade shell 11 and the web 13 are bonded by an adhesive (adhesive layer 12), so as to improve the blade's tolerance to shear force; Test block 2 ( figure 2 shown) also includes the blade shell 21, the adhesive layer 22, the web 23 and the through hole 24, wherein the material of the blade shell 21, the adhesive layer 22, and the web 23 of the test block 2 is consistent with the web to be inspected and The materials of the blade shell 11 , the adhesive layer 12 and the web 13 in the beam bonding workpiece 1 are the same. There is a through hole 24 at the position of the adhesive layer 22 and the web 23 on the test block 2, and the through hole 24 meets the minimum process defect requirement. According to step 5 of the present invention, the probe 3 is placed on the test block 2 to calibrate the ultrasoni...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com