An intelligent vegetable washing and cutting all-in-one machine suitable for tall cabbage

A technology of high-stalk cabbage and an all-in-one machine, applied in the direction of cleaning methods, applications, cleaning methods and utensils using liquids, can solve economic losses, reduce production efficiency, uneconomical and environmental protection, etc., to ensure cleanliness and sanitation, ensure material quality, and the effect of improving cleaning efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0033] The present invention will be described in further detail below in conjunction with the accompanying drawings and specific embodiments.

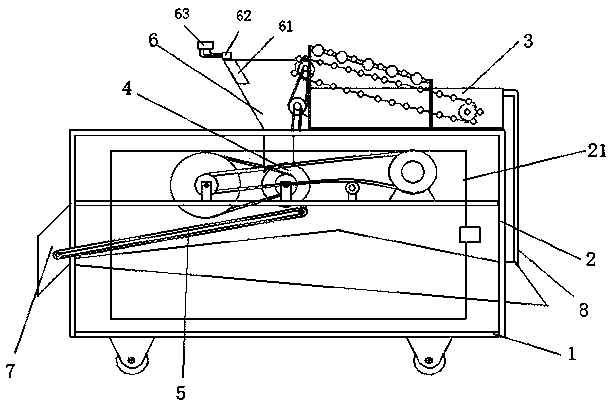

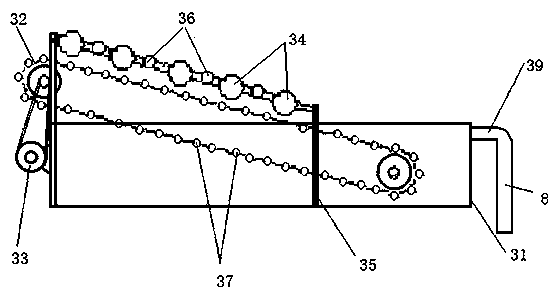

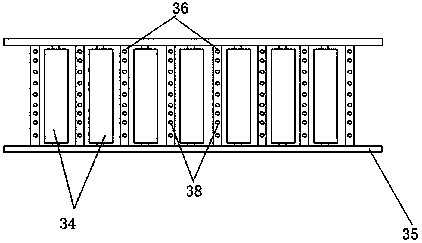

[0034] Such as figure 1 An intelligent vegetable washing and cutting machine suitable for high-stem cabbage is shown, including a frame 1, a cover body 2, a cleaning mechanism 3, a slicing mechanism 4, an output mechanism 5, a material inlet 6 and a material outlet 7, Wherein, the cover body 2 is located above the frame 1, the slicing mechanism 4 and the output mechanism 5 are located in the cover body 2, the cleaning mechanism 3 is located at the material inlet 6 at the upper end of the cover body 2, and the front and rear ends of the cover body 2 are provided with There are movable windows 21, and the stems of high-dried cabbage are long. First, they are cleaned by the cleaning mechanism 3, and then transported to the material inlet 6 and entered into the slicing mechanism 4 for cutting. The cut materials are then transported to the...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com