Automatic oil suction device

A driving device and oil pumping technology, applied in the direction of measuring device, sampling device, sampling, etc., can solve the problems of affecting operation, low efficiency, prolonging oil pumping time, etc., and achieve the effect of preventing chronic diseases and high efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

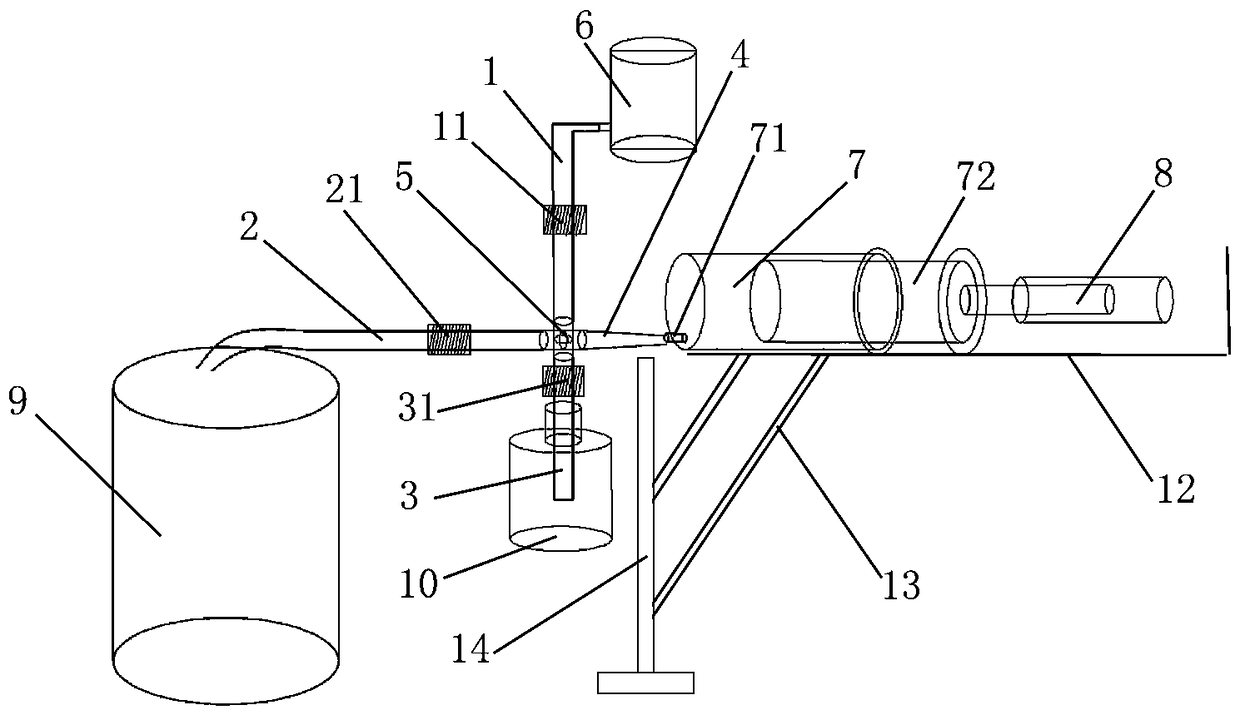

[0016] The present invention will be described in further detail below in conjunction with the accompanying drawings.

[0017] Such as figure 1 As shown, the present invention includes a four-way valve 5, the four ports of the four-way valve 5 are respectively connected with an air inlet pipe 1, a liquid discharge pipe 2, a sampling pipe 3 and a sampling pipe 4, and the air inlet pipe 1 is provided with a first A valve 11, and the outlet end of the inlet pipe 1 is connected with a carrier gas source 6, the discharge pipe 2 is provided with a second valve 21, and a waste liquid recovery container 9 is placed at the outlet of the discharge pipe 2 to recycle waste liquid, to avoid residual oil pollution, the sampling tube 3 is provided with a third valve 31, the outlet end of the sampling tube 4 is connected to the injection port 71 of the syringe 7, in order to ensure the tightness of the connection between the sampling tube 4 and the syringe 7, In this embodiment, the sampling...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com